KOBE INDUSTRIAL POWER TOOLS

have been specifically designed to help you work SAFELY

and EFFICIENTLY. Your care and good judgement are the best protection against injury, but always ensure

that the appropriate safety equipment is worn. All possible hazards cannot be covered here, but the most

relevant ones have been highlighted.

SAFETY INSTRUCTIONS

2

GENERAL OPERATING HAZARDS

ALWAYS use the Hot Air Gun with care as misuse

could cause a fire.

ALWAYS disconnect from the electrical power

supply before cleaning or carrying out user

maintenance.

ALWAYS wear non-skid safety footwear when

working outdoors.

ALWAYS ensure the maintenance of electrical

components, including plug fitting, is carried out

by a suitably qualified person.

ALWAYS store the tool in a dry, secure place away

from children.

NEVER use electrical power tools when they are

damp or in a damp or wet environment.

NEVER operate the Hot Air Gun when tired or

under the influence of alcohol or prescription/non-

prescription drugs.

NEVER operate if any parts are missing or

damaged.

WORKPLACE HAZARDS

ALWAYS beware of fire and ignition hazards.

Exercise care when using the Hot Air Gun in the

proximity of flammable materials. Heat may also

be conducted to flammable materials that are out

of sight. This tool is not intended for use in a

flammable or combustible atmosphere.

ALWAYS keep the electric cable away from heat,

oil and sharp edges.

ALWAYS use a RCD (Residual Current Device) to

provide protection against electric shock.

ALWAYS make sure the area in which you are

working in has a good flow of air. Toxic gases may

occur when working on plastics, paints, varnishes

or similar materials.

PERSONAL PROTECTION

ALWAYS wear approved eye protection during

operation.

ALWAYS wear gloves to protect hands from cuts

and burns.

SPECIFIC OPERATING HAZARDS

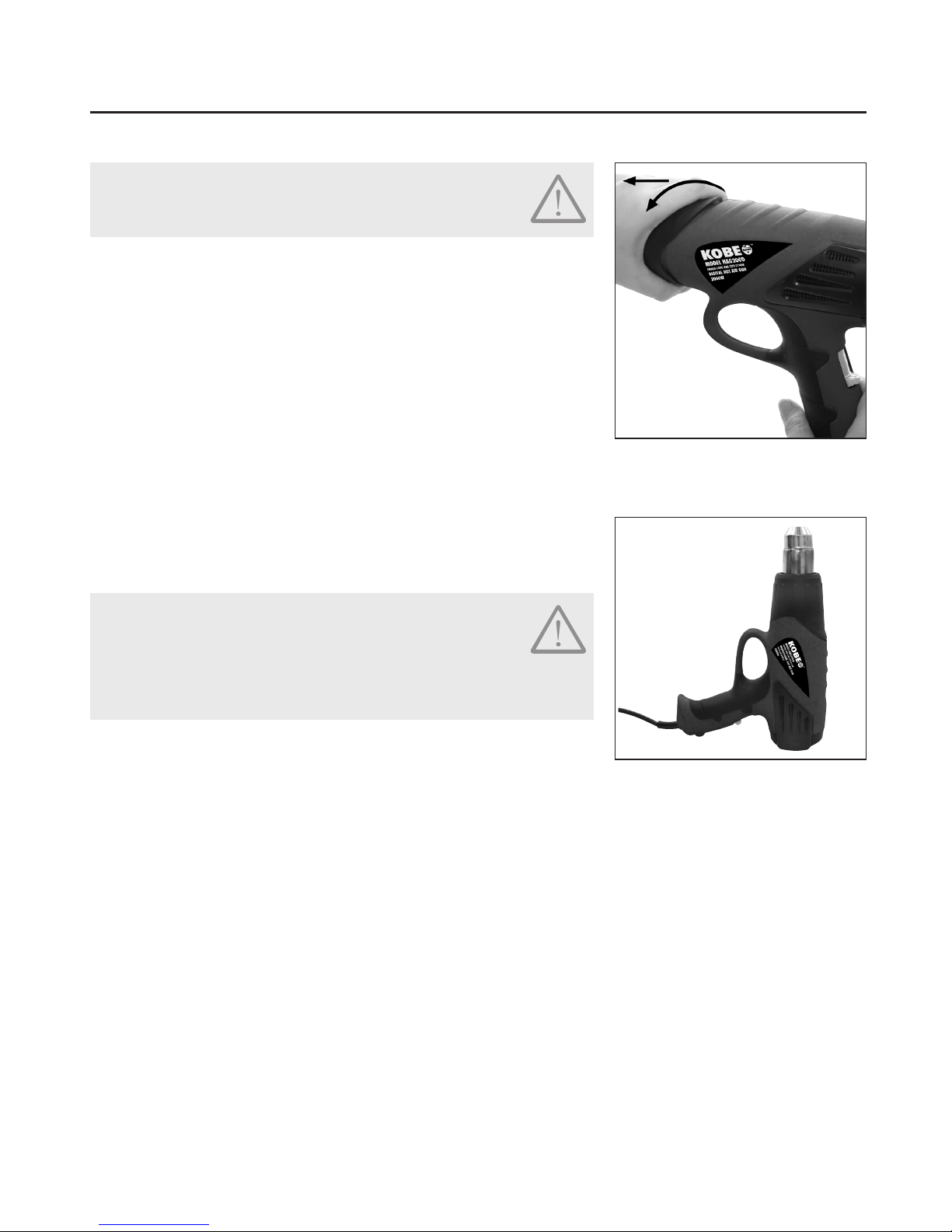

ALWAYS ensure the Hot Air Gun is switched OFF

before connecting it to the power supply.

ALWAYS use recommended attachments or parts.

ALWAYS ensure the electric cable is not damaged

before connecting the Hot Air Gun to the electricity

supply.

ALWAYS place the tool in its freestanding (see Fig 5,

on page 5

)

position after use and allow

to cool before putting it away. The nozzle reaches

temperatures in excess of 600°C.

NEVER use the Hot Air Gun as a hair dryer.

NEVER direct the flow of hot air at persons or

animals.

NEVER point the heat gun directly at a window or

other glass surfaces.

NEVER leave the Hot Air Gun running whilst

unattended.

NEVER direct the Hot Air Gun onto the same spot

for any prolonged period.

NEVER make any alterations to the Hot Air Gun

and only use it for the task for which it has been

designed.

NEVER insert objects inside the air intake.

NEVER position too close to the work piece as the

air flow will be restricted and may cause the Hot

Air Gun to overheat. Position the nozzle at least

25mm away from the work surface.

NEVER carry the tool by the power cord.

NEVER unplug the tool by pulling on the power

cord.

NEVER allow children to use the unit.

You have purchased a quality industrial product that is designed for high performance

and long service life. If correct use, safety and maintenance procedures are observed

this machine will last for many years.