CAUTION

If position of nozzle is lower than liquid level in the drum,

liquid may leak from nozzle due to Siphon phenomenon.

Put out this pump from drum before storage.

HOW TO USE

CAUTION AFTER USE

MAINTENANCE .CHECK

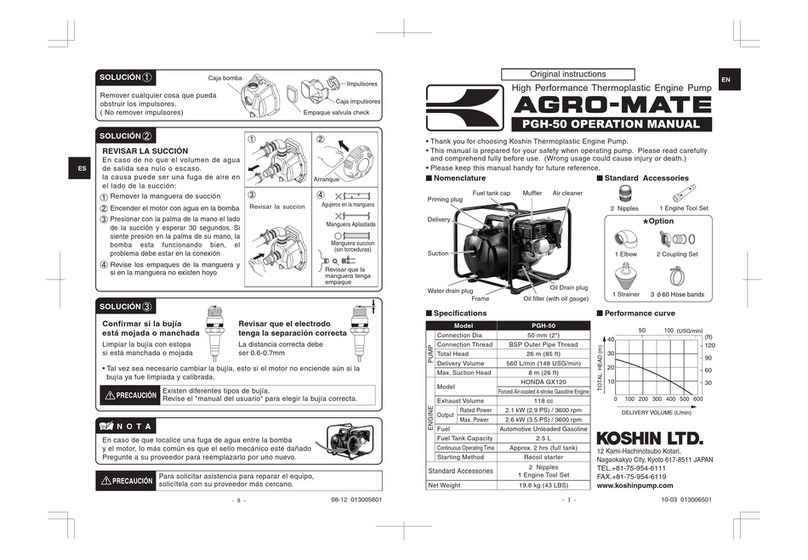

1Insert suction pipe into Drum.

Fix Drum screw onto the collar.

Turn Drum Nut to fix.

2Make sure Power Switch is

"OFF" and Lever Lock of

Nozzle is released,

then, connect power plug.

3Put Power Switch "ON" and grip the Lever of Nozzle.

4If you use Lever Lock, pump will transfer oil continuously.

Release lever lock when stop continuous operation.

1. After using pump, switch power to "OFF". Release Lever Lock of Nozzle, then,

remove electric plug from socket.

2. Remove pump from the drum. Remove oil in the suction pipe, hose, and nozzle.

Wipe off excess oil on the surface of the pump with a duster.

3. Storage

Please keep pump clean, in low humidity, well-ventilated, indoor, away

from sunlight.

4. Clean Strainer if you do not use this pump for long time.

(Refer Maintenance, Check)

[Cleaning of Strainer .Impeller]

If dust obstruct Strainer or Impeller, it may cause inferior suction, inferior

flow, shorten pump's life and damage of motor. Make sure electric plug

is removed from socket and check following points regularly.

Casing

Strainer

Remove

Impeller

Casing

Strainer

Remove

Impeller

[Replacement of Fuse]

A fuse may burn out to protect motor damage if surplus current enters

the motor. It is necessary to replace a fuse in this case.

①Remove Strainer by turning towards

indicated direction, remove all dirt

and dust.

②Remove Casing and clean up dust

inside the Impeller.

③After cleaning, re-assemble

by reverse course.

Do not be near fire during operation

DANGER

TROUBLE SHOOTING AND MAINTENANCE

First, put the pump into drum and then,

make the switch ON. If position of nozzle is

lower than liquid level

in the drum, liquid may

leak from nozzle due to

Siphon phenomenon.

Put out this pump from

drum before storage.

Condition Possible Cause Measure

A

B

Oil leakage

Tighten hose cap firmly

Remove liquid inside hose

and keep position of hose

higher than the pump before

storage

Tighten screw

Cleaning

Straighten hose

Fill liquid into the drum

Shorten the hose.

Turn power switch to "Off"

and re-start

Check electric plug and

socket.

Ask repair by local

distributor / dealer

Reduce extension cord length

Take corrective action for the

cause of the blown fuse and

replace the fuse.

(Refer to MAINTENANCE .

CHECK)

Open pump and clean

SPARE PARTS

CAUTION

After fixing the pump to the drum, please do not operate pump or

drum at oblique condition.

CAUTION

Please lay down the pump during storage to avoid inversion.

CAUTION

After use, do not put pump on the ground directly. If dust gather at

the strainer, it may cause future inferior suction or damage.

CAUTION

Please do not dismantle or repair the pump by yourself.

Please ask for repair work from your local distributor /dealers.

DANGER

If do not release the lever lock, the outflow of oil does not stop.

To avoid a oil overflow, please operate carefully

PROHIBITED

When Power Switch is "ON" and motor is running, please do not

leave pump with Lever Lock for more than 3 minutes. (It might cause

damage or accident.)

CAUTION

When you loosen "Drum Nut", hold the pump body by another hand.

Otherwise, pump body may drop suddenly and cause injury or damage.

CAUTION

During maintenance and check, always turn switch to "OFF" and remove

electric plug from socket. Otherwise may cause accident or injury.

For spare parts information, visit http://www.koshinpump.com

No discharge

(No suction)

Pump does

not work

Dirt & dust inside pump

Voltage drop when using extension

cord

Motor does not work

Air-Lock inside pump

Hose is too long ( in case of extension)

No liquid, not enough flow In the drum

Strainer is clogged with dust

Bending hose

Sealing failure of packing caused by

screw loosening.

Hose cap is not tightened enough

Leakage due to Siphon phenomenon

Disconnection of power cord

(Check power lamp is light "ON" or not.)

Electric plug does not sit well Into the

socket (Check power lamp is light

"ON" or not.)

Burn out Fuse

*In such case, power lamp is light "ON"

No discharge

(No suction)

or, small

discharge

volume -

pump is

working.

Oil leakage

from connection

part of hose

Oil leakage

from nozzle

A B

①Remove fuse cover by + screw driver,

turn counterclockwise.

②Remove fuse, check if it is "burn out"

then, replace with new 4 A fuse.

Do not use fuse other than 4A.

③Please re-assemble by reverse course.

Remove

Fuse Remove

Fuse

+Screw driver

+Screw driver

CAUTION

If the fuse blows frequently, the oil seal of the motor may be worn

out, and kerosene or light oil may have entered the motor and the

fuse may blow due to overload.

Please ask for repair work from your local distributor / dealers.

Drum Nut

Drum Screw

tightentighten loosenloosen

Fixing = Continuous

Release = Stop

Lever Lock