Contents

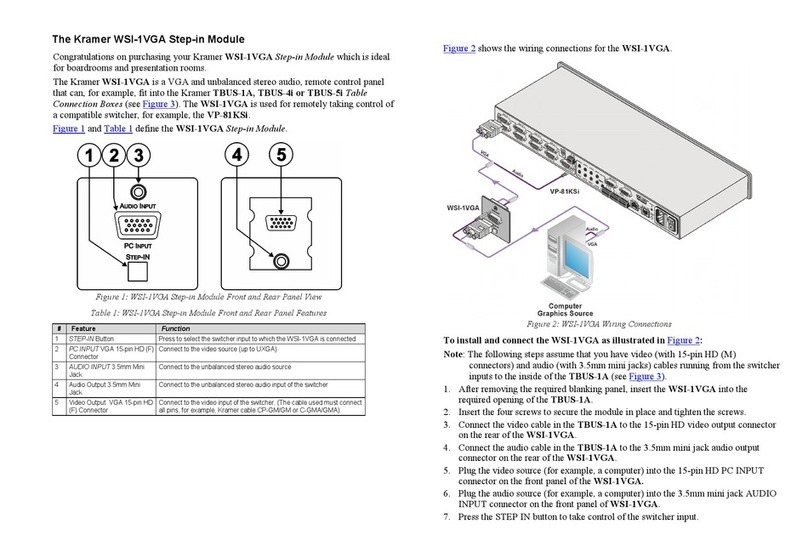

1Introduction 1

2Getting Started 1

2.1 Achieving the Best Performance 2

2.2 Safety Instructions 2

2.3 Recycling Kramer Products 2

3Overview 3

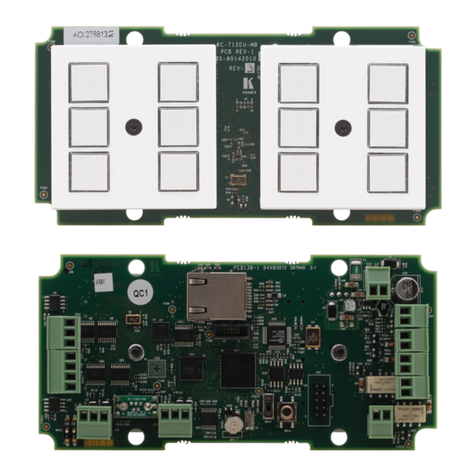

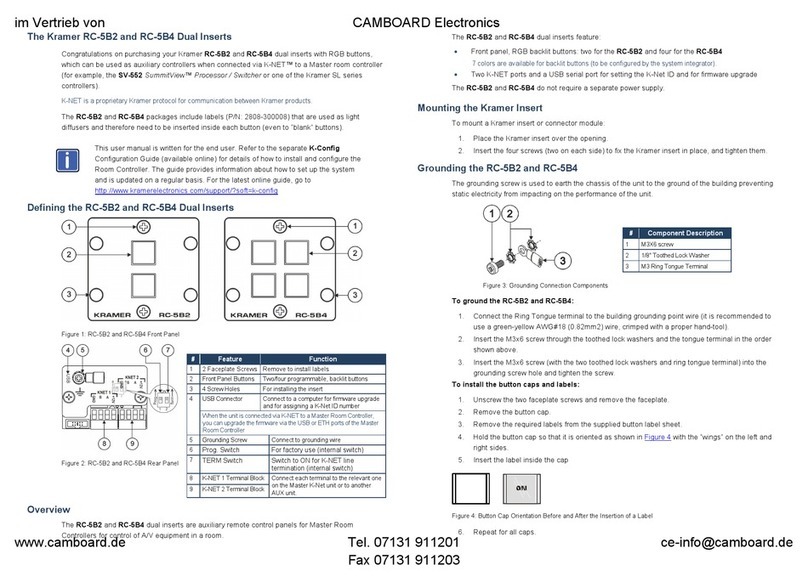

4Defining the RC-53DLC 4

4.1 RC-53DLC for the US 4

4.2 RC-53DLC for Europe 6

4.3 Grounding the RC-53DLC 8

5Using the RC-53DLC K-NET™ Auxiliary Control Panel 9

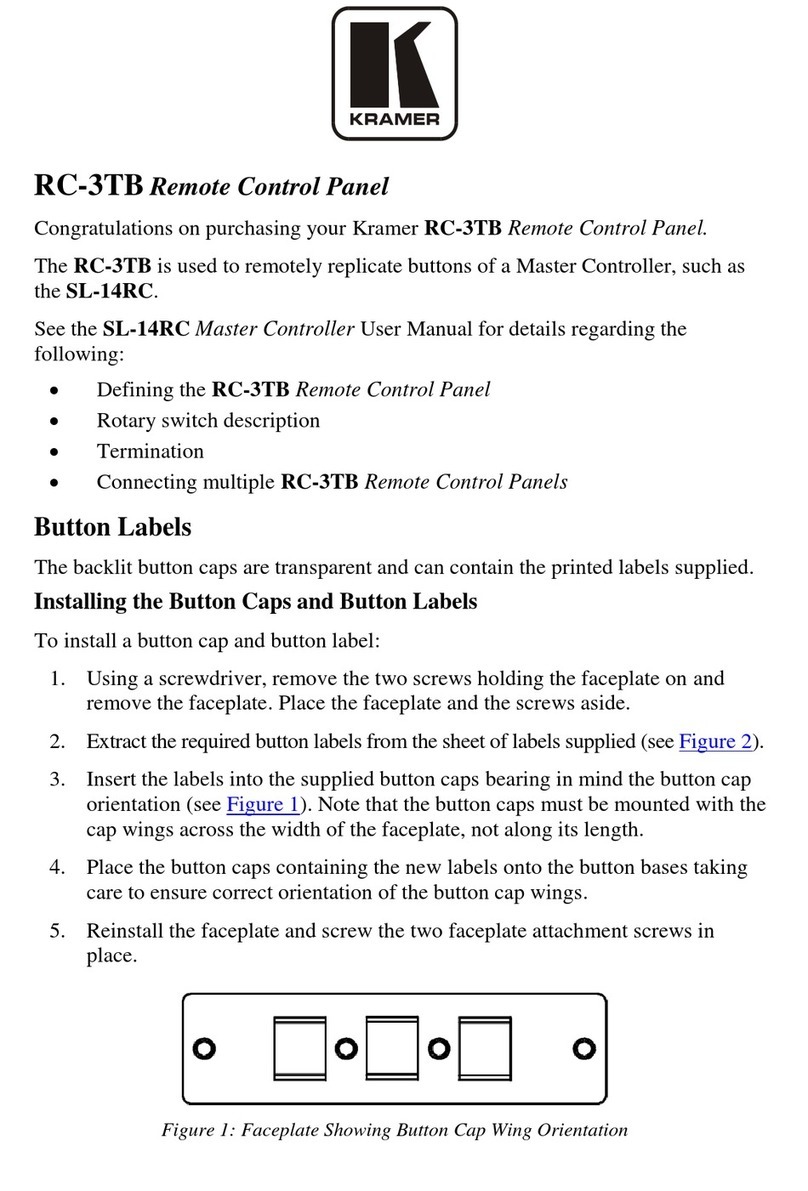

6Installing the RC-53DLC Faceplate, Button Caps and Labels 10

7Operating the RC-53DLC K-NET™ Auxiliary Control Panel 12

8Technical Specifications 13

Figures

Figure 1: RC-53DLC US Version –Front Panel 4

Figure 2: RC-53DLC US Version –Rear Panel 5

Figure 3: RC-53DLC European Version –Front Panel 6

Figure 4: RC-53DLC European Version–Rear Panel 7

Figure 5: Grounding Connection Components 8

Figure 6: RC-53DLC connected to the SV-551 SummitView™ Processor / Switcher 9

Figure 7: Sample Button Label Sheet 10

Figure 8: Button Cap Orientation 10

Figure 9: Inserting the Label 10

Figure 10: Placing the Button Cap 11

Figure 11: RC-53DLC Labels Setup 12

Tables

Table 1: RC-53DLC K-NET™ Auxiliary Control Panel – Front Panel Features 4

Table 2: RC-53DLC US Version –Rear Panel Features 5

Table 3: RC-53DLC European Version –Front Panel Features 6

Table 4: RC-53DLC European Version –Rear Panel Features 7

Table 5: Grounding Component Descriptions 8

Table 6: The Commands Configuration 12

Table 7: Technical Specifications of the RC-53DLC K-NET™ Auxiliary Control Panel 13