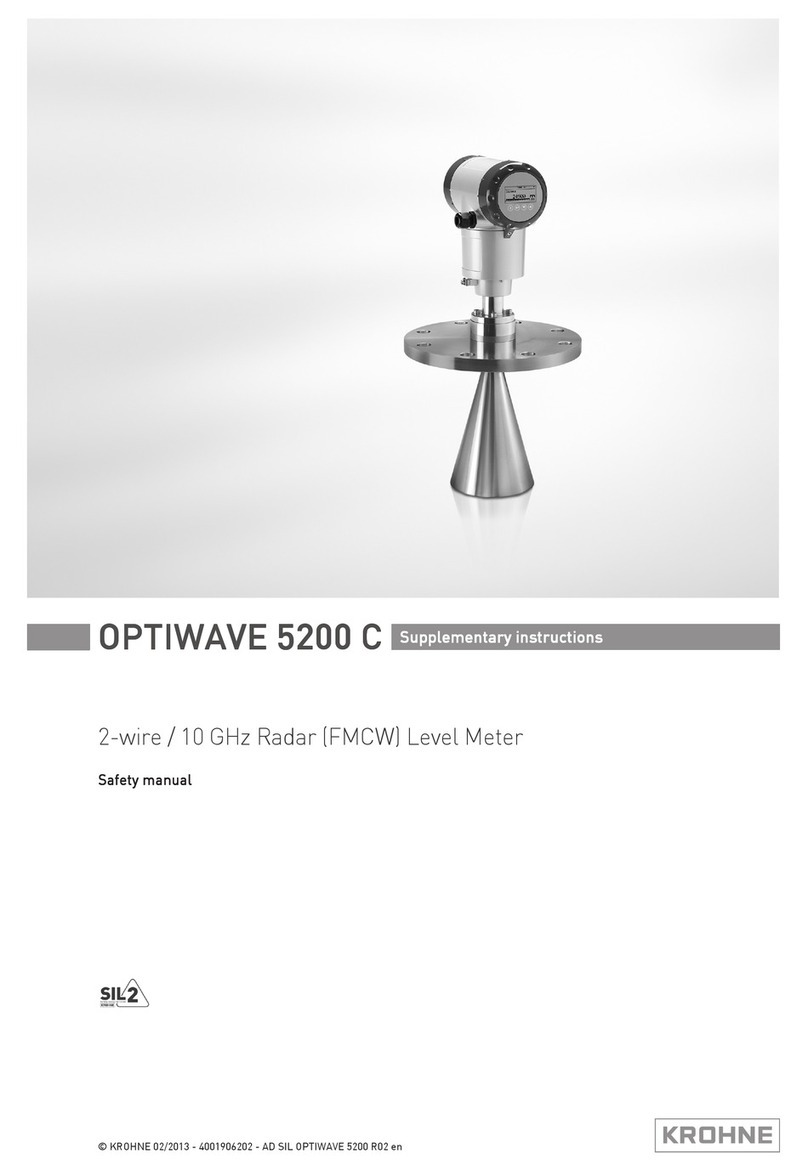

It is designed for industrial use in all areas of process

technology and is used in liquids.

Typical applications are overfill and dry run protection.With a

tuning fork of only 40 mm length,OPTISWITCH 5200 C,5250

Ccan be also mounted,e.g.in pipelines from DN 25.The

small tuning fork allows the use in vessels,tanks and pipes.

Thanks to its simple and robust measuring system,OPTI-

SWITCH 5200 C,5250 Cis virtually unaffected by the

chemical and physical properties of the liquid.

It functions also under difficult conditions such as turbulence,

air bubbles,foam generation,buildup,strong external vibration

or changing products.

Fault monitoring

The electronics module of OPTISWITCH 5200 C,5250 C

monitors continuously the following criteria via the frequency

evaluation:

lstrong corrosion or damage of the tuning fork

lno vibration

lline break to the piezo drive

If a fault is detected or in case the power supply fails,the

electronics takes on a defined switching condition,i.e.the

output transistor blocks (safe condition).

OPTISWITCH 5200 C,5250 Cfulfills the requirements of

IEC 61508 and 61511 of SIL2(see Supplement).

The tuning fork is piezoelectrically energised and vibrates at its

mechanical resonance frequency of approx.1200 Hz.The

piezos are fixed mechanically and are hence not subjected to

temperature shock limitations.The frequency changes if the

tuning fork is covered by the medium.This change is detected

by the integrated oscillator and converted into a switching

command.

OPTISWITCH 5200 C,5250 Cis a compact instrument,i.e.it

can be operated without external evaluation system.The

integrated electronics evaluates the level signal and outputs a

switching signal.With this switching signal,a connected

device can be operated directly (e.g.a warning system,aPLC,

a pump etc.).

The exact range of the power supply is stated in the Technical

data in the Supplement.

Physical principle

Power supply

8OPTISWITCH 5200 C,5250 C-with transistor output

Product description

30432-EN-050622