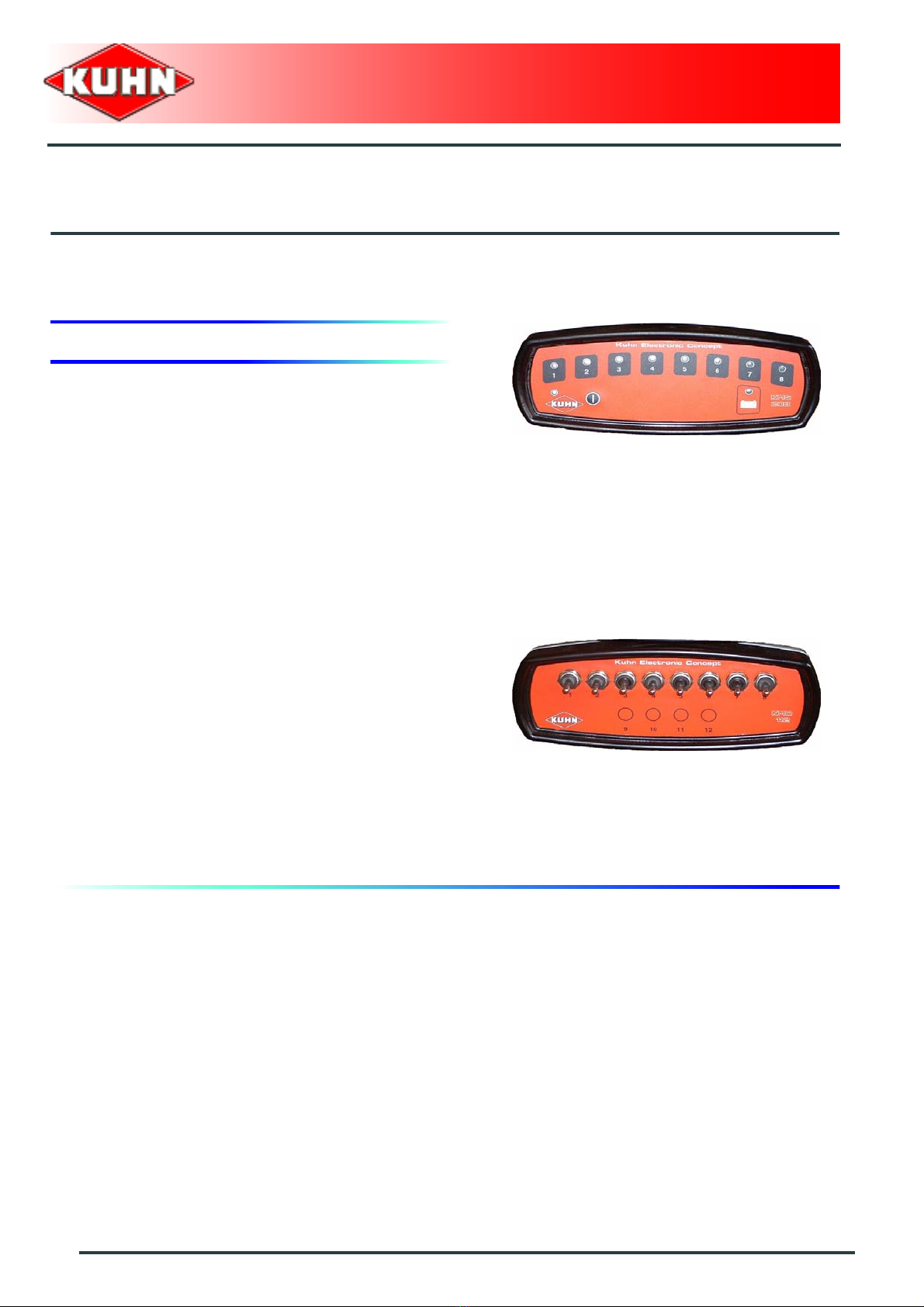

Precision Seed Drills

2

KMS208-KMD112

Contents

$CONTENTS

Dear Owner..................................................................................................................... 1

Contents.......................................................................................................................... 2

Safety .............................................................................................................................. 3

Description of symbols used in this document ............................................................................ 3

General description ......................................................................................................................... 4

Description ....................................................................................................................................... 4

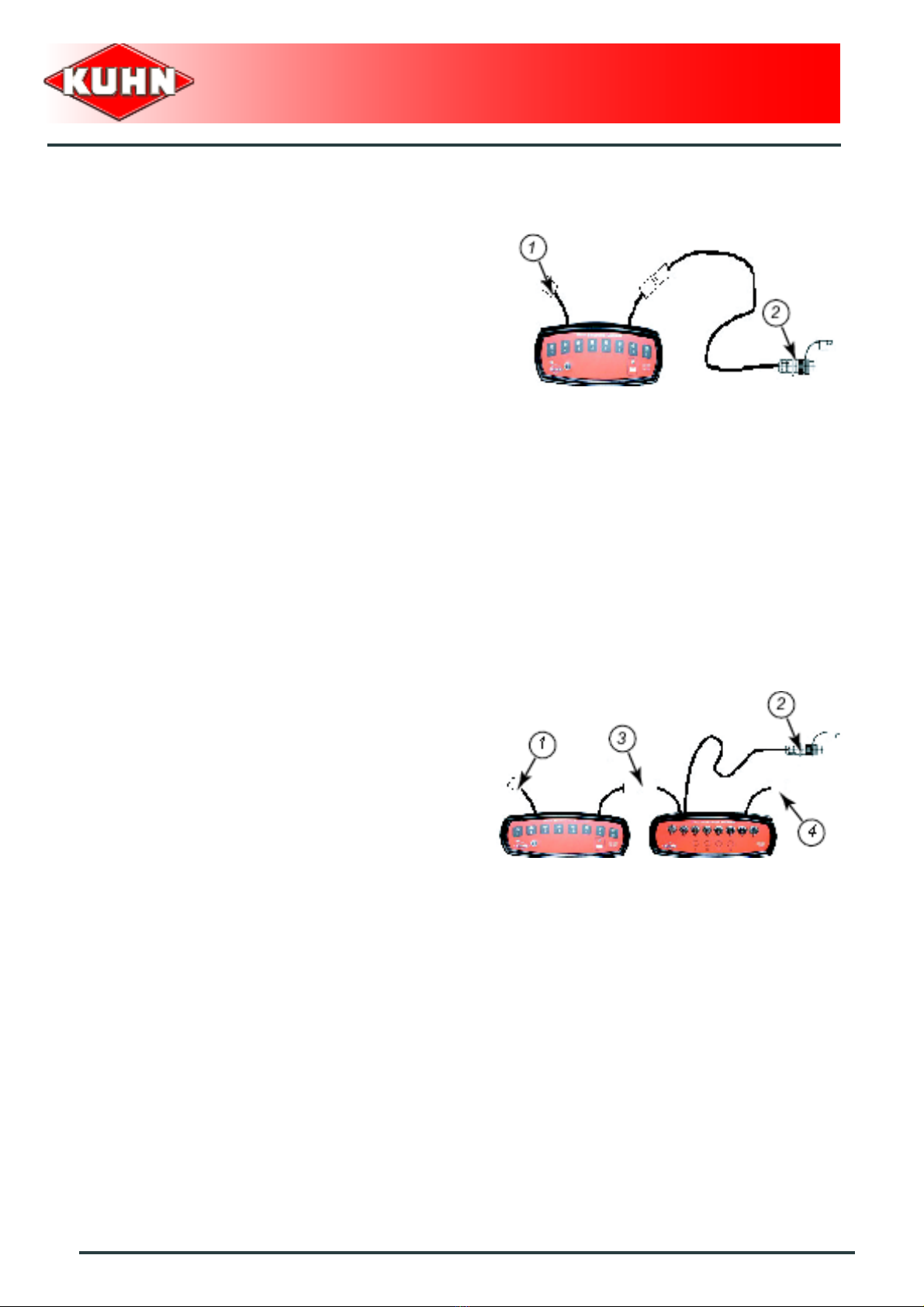

Description of the connection ........................................................................................................ 5

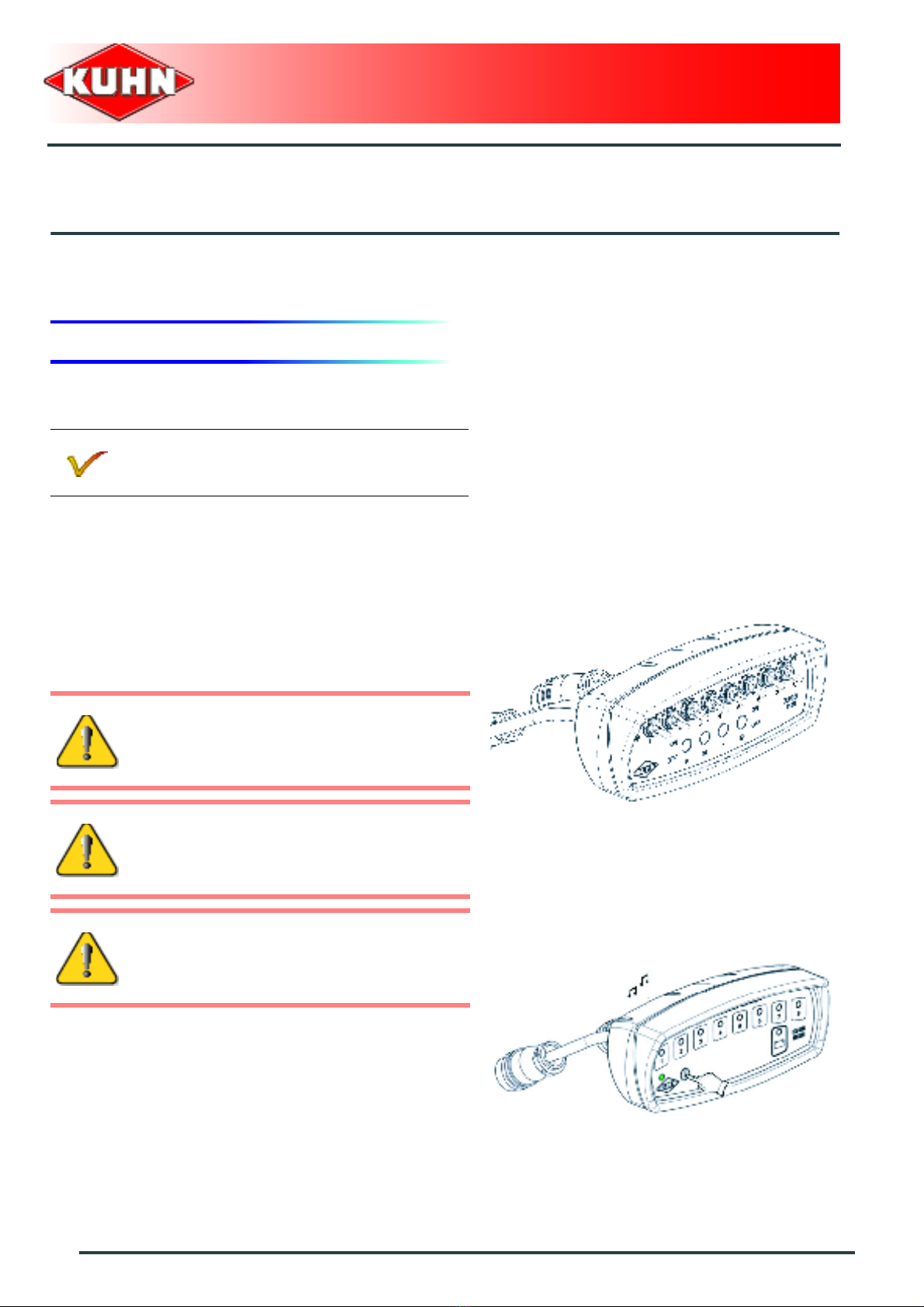

Putting into service........................................................................................................ 8

Operation.......................................................................................................................................... 8

Trouble shooting guide ................................................................................................................. 18

Wiring diagram of the main cell harness..................................................................................... 22

Wiring diagram of the main declutching mechanism harness.................................................. 23

Connector connection................................................................................................................... 24

Installation diagram ..................................................................................................... 25

KMS208 on MAXIMA...................................................................................................................... 25

KMS208 and KMD112 on MAXIMA................................................................................................ 26

KMS208 and KMD112 on PLANTER ............................................................................................. 27

KMS208 on PLANTER.................................................................................................................... 28

Limited warranty .......................................................................................................... 29