- 7 -

SPECIAL SAFETY RECOMMENDATIONS

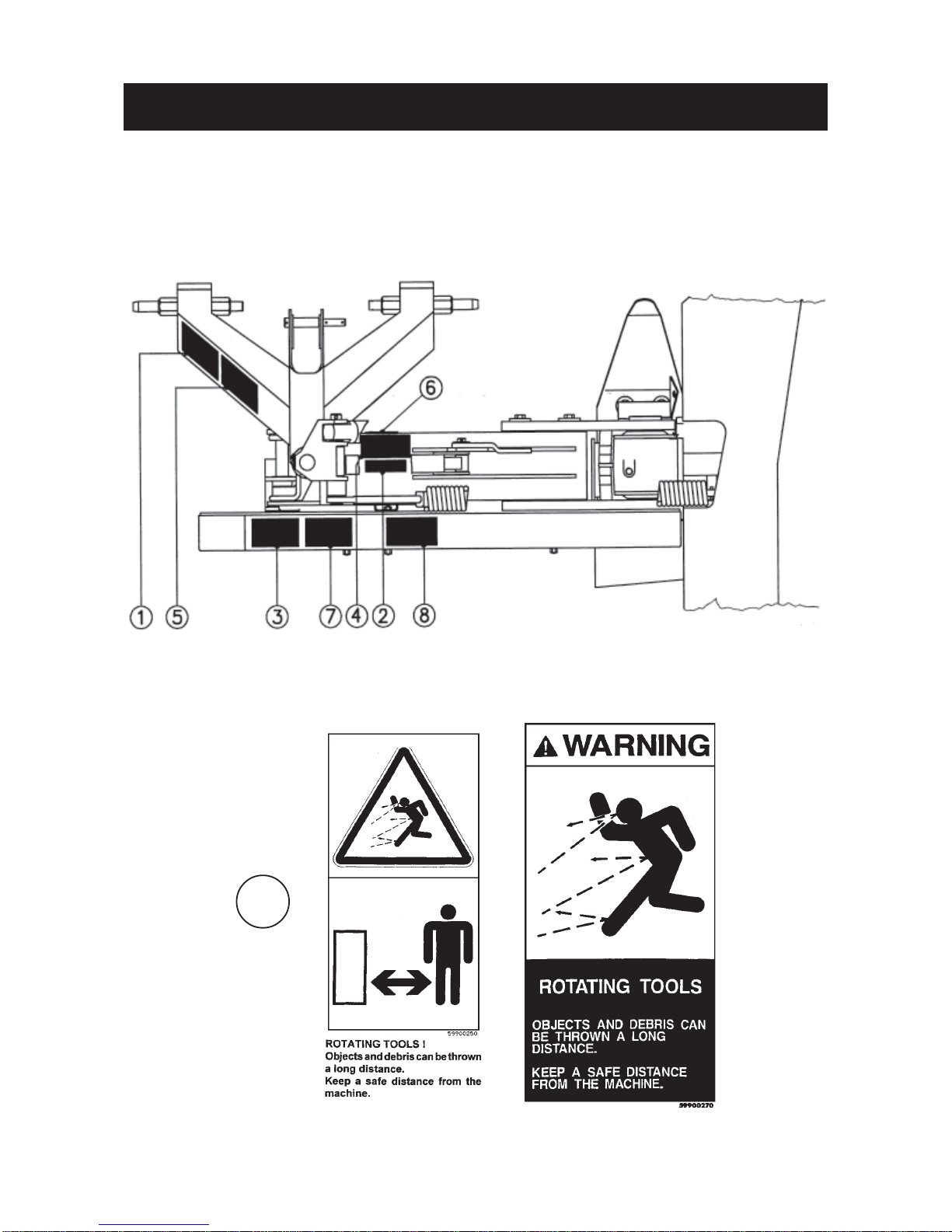

1. Use a tractor equipped with an enclosed cab with windows made of safety glass and kept closed. It is

recommendedtofitpolycarbonatescreensinsidethetractorsafetycab'ssideandrearwindowsortoinstallmesh

guardson the exteriorof them.

2. Stay a safe distance away from the mower when discs are rotating.

3. For safe machine operation, it is imperative that cutting tools be fitted in accordance with the manufacturer’s

recommendations. Use only the tool outfit supplied with the machine.

4. Eachtimebeforeusingthemower,inspectconditionofcuttingelements(knives,discs).Replaceanymissing,

wornordamagedcutting elements immediately. Use onlygenuineKUHNspareparts.

5. Toavoidcreatingdangerousoutofbalanceforces,alwaysreplacemissing,damagedorwornknivesinpairs.

6. When replacing knives or discs, systematically inspect their securing elements as per the manufacturer’s

recommendations.

7. Regularly inspect the disc mower’s protection cover. Worn or damaged protection covers must be replaced

immediately.

8. Protectiondevices(suchasguards,shieldsetc.)areintendedtopreventstones,rocksorotherforeignobjects

frombeingprojected.Theyalsopreventaccesstothemachine’sdangerzones.Therefore,itisimperativethat

protectiondevicesare put in placeandproperly secured each timebeforeusing the machine.

9. Crushingandshearingzoneswhichcouldcauseseriousbodilyinjurywhenchangingthemachinefromtransport

towork positionandviceversamayexist. Topreventpossibleinjury,beextra carefulwhenmaneuveringand

ensure that everyone is at a safe distance away from the machine.

10.PTOdrivetothemowermustneverbeengagedunlessthecutterbarskidshoesareincontactwiththeground

andtheprotectivecoverisfoldeddown.

11.Groundof thepastures to bemown must befree of foreignobjects.

12.Even when the machine is used in accordance with its purpose, objects may be projected. It is therefore

imperativethateveryonebekeptawayfromthedangerzone,thatextracarebetakenandthatextra precaution

(suchassafetyindicators)betakenwhenmowingpasturesalongsideroadsornearpublicareas(parks,schools

etc.).

13.Nevermowinreverse.

14.WhendisengagingthePTOdrive,movingpartscontinuetorotateforsometime.Waitforallmovingpartstocome

toacompletestopbefore approaching the machine.

15.Ifanobstructionishit,stopthetractorimmediately,disengagePTOdrive,turnoffengine,removeignitionkey

and wait for all moving parts to come to a complete stop.

Checktheentiremachineforanydamagebeforeresumingwork.

16.Itisstronglyrecommendedtohaveyourmachinecheckedbyyourdealeraftereachseason,especiallyblades

and discs and their fixing devices (nuts, bolts etc.).