Contents

? KUKA Roboter GmbH 2005 / SM KR30-3 09.05.00 en Page 3 of 140

Contents

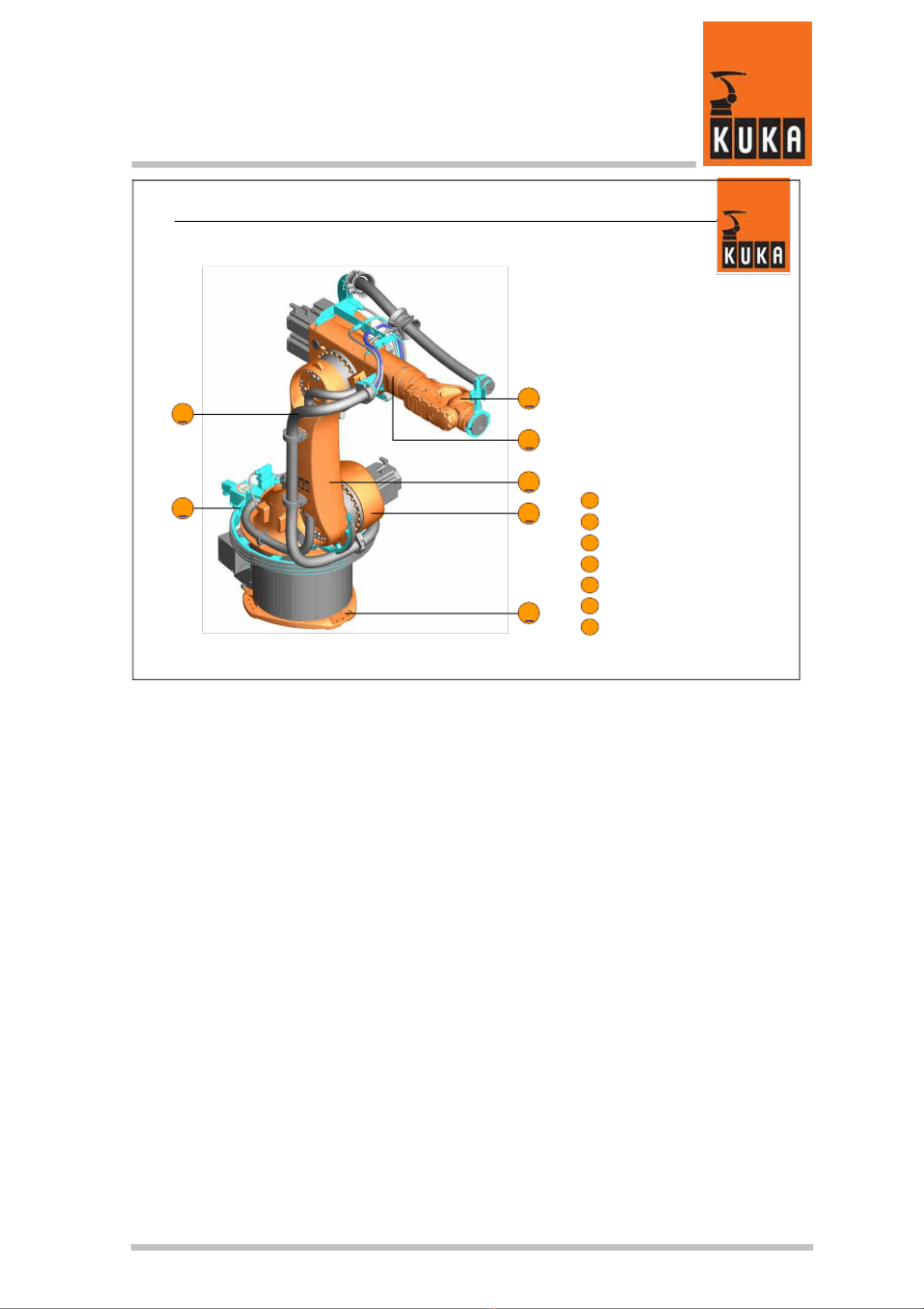

1. Overview Robot............................................................................. 5

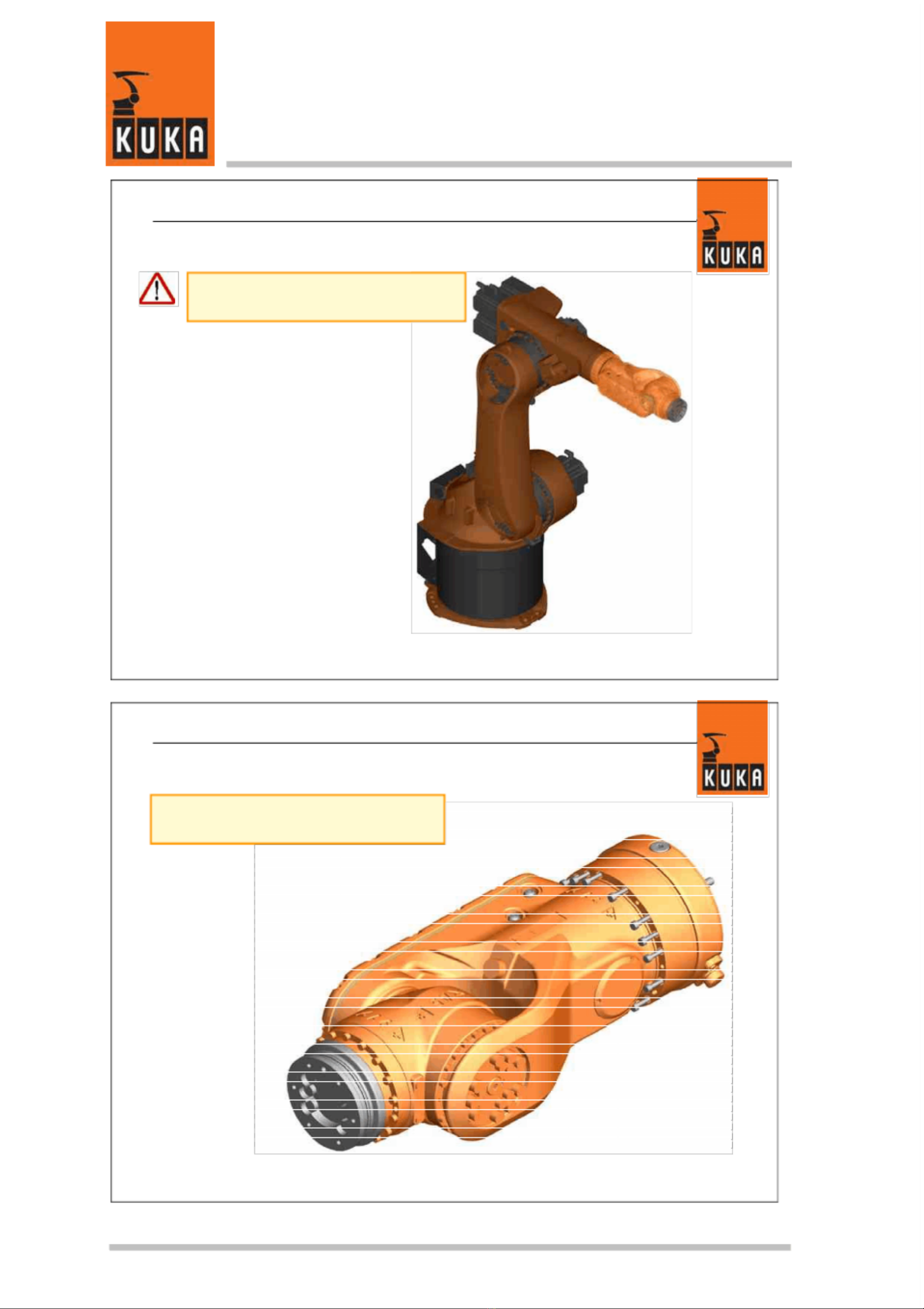

2. Disassembly .................................................................................. 9

2.1. Wrist ....................................................................................... 9

2.2. Arm....................................................................................... 13

2.3. Link arm ............................................................................... 21

2.4. Rotating column ................................................................... 27

2.5. Base unit .............................................................................. 35

2.6. Energy supply ...................................................................... 37

2.7. Axis monitoring..................................................................... 51

3. Assembly..................................................................................... 55

3.1. Base unit .............................................................................. 55

3.2. Rotating column ................................................................... 57

3.3. Link arm ............................................................................... 63

3.4. Arm....................................................................................... 69

3.5. Wrist ..................................................................................... 75

3.6. Energy supply ...................................................................... 81

3.7. Axis monitoring..................................................................... 95

4. Maintenance................................................................................ 99

4.1. Wrist axes ............................................................................ 99

4.2. Basic axes..........................................................................109

5. Exercises...................................................................................113

6. Tightening torques table............................................................139