KVH Industries TracPhone V11 hts User manual

Other KVH Industries Antenna manuals

KVH Industries

KVH Industries SAILOR 4300 Quick guide

KVH Industries

KVH Industries TracVision L3 User manual

KVH Industries

KVH Industries TracPhone V3IP User manual

KVH Industries

KVH Industries TracVision HD7 User manual

KVH Industries

KVH Industries TracPhone V7-IP User manual

KVH Industries

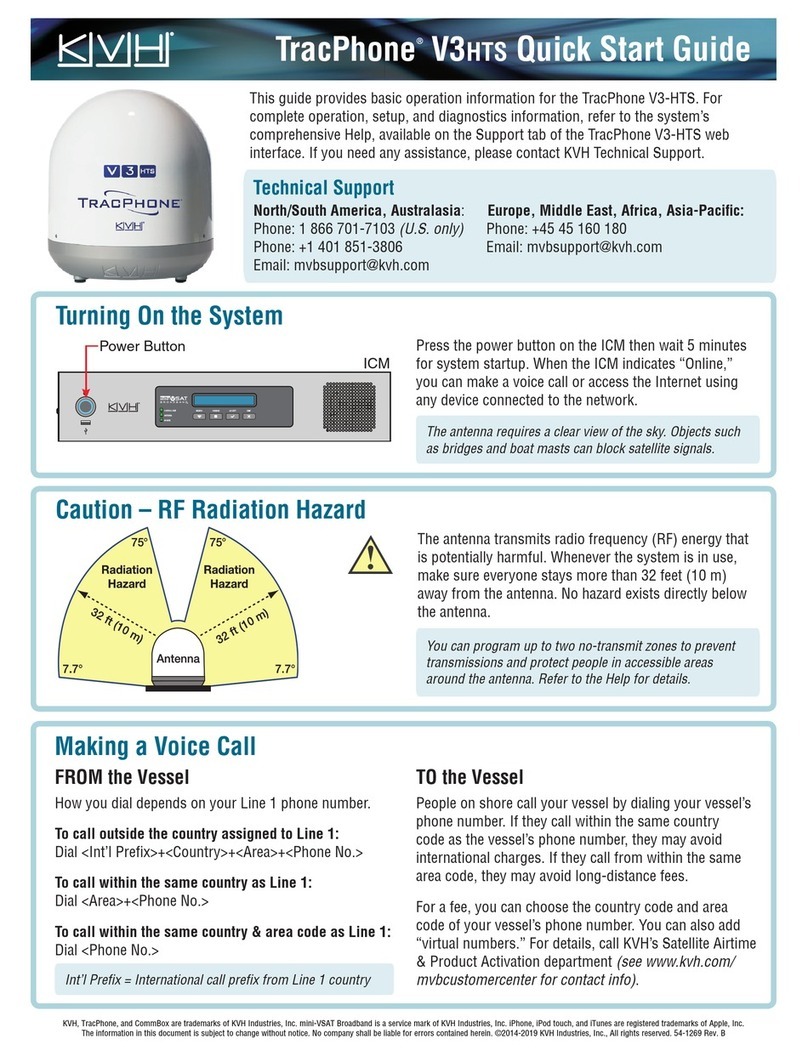

KVH Industries TracPhone V3HTS User manual

KVH Industries

KVH Industries TracPhone V30 Installation and operating instructions

KVH Industries

KVH Industries TracVision TV1/RV1 Guide

KVH Industries

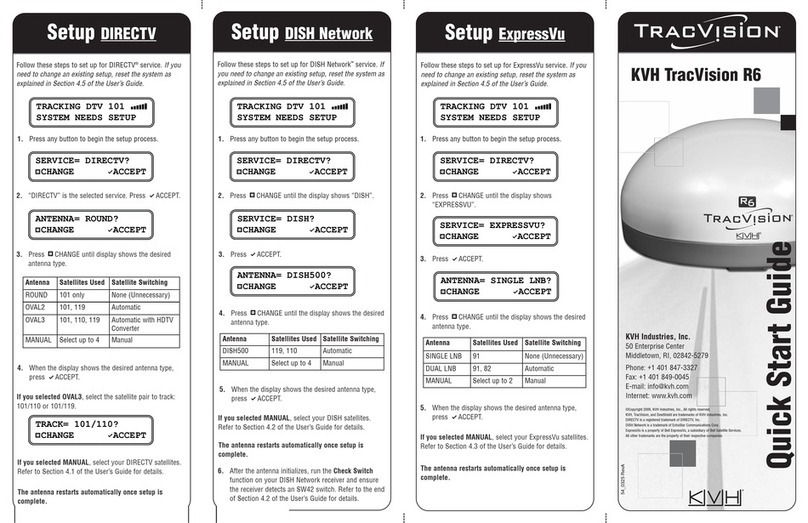

KVH Industries TracVision R6 DX User manual

KVH Industries

KVH Industries TracVision 6 User manual

KVH Industries

KVH Industries TracVision 6 User manual

KVH Industries

KVH Industries FB250 User manual

KVH Industries

KVH Industries TrackPhone V7 User manual

KVH Industries

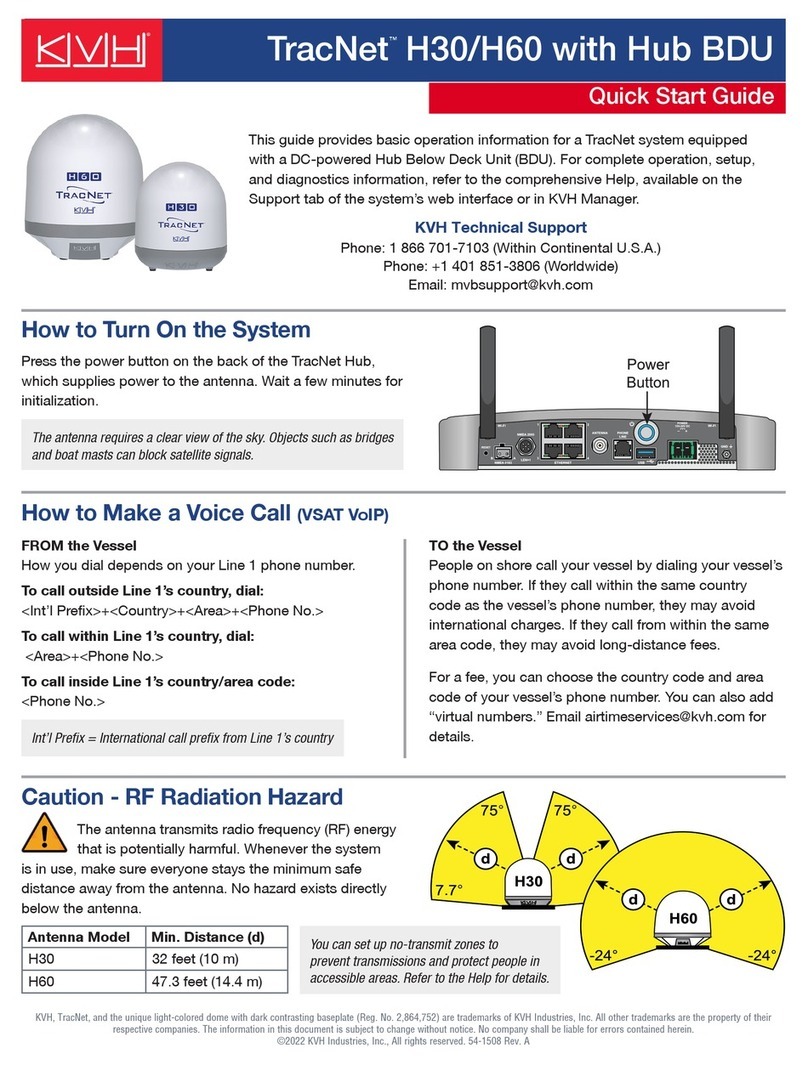

KVH Industries TracNet H30 User manual

KVH Industries

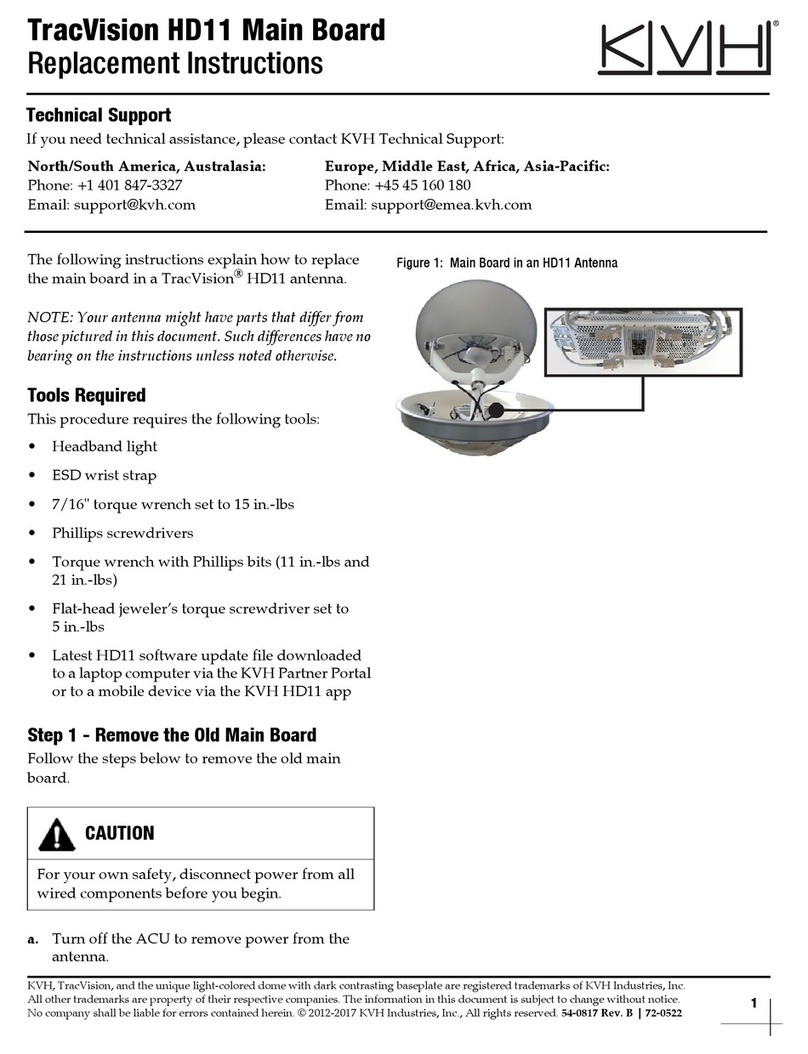

KVH Industries TracVision HD11 Guide

KVH Industries

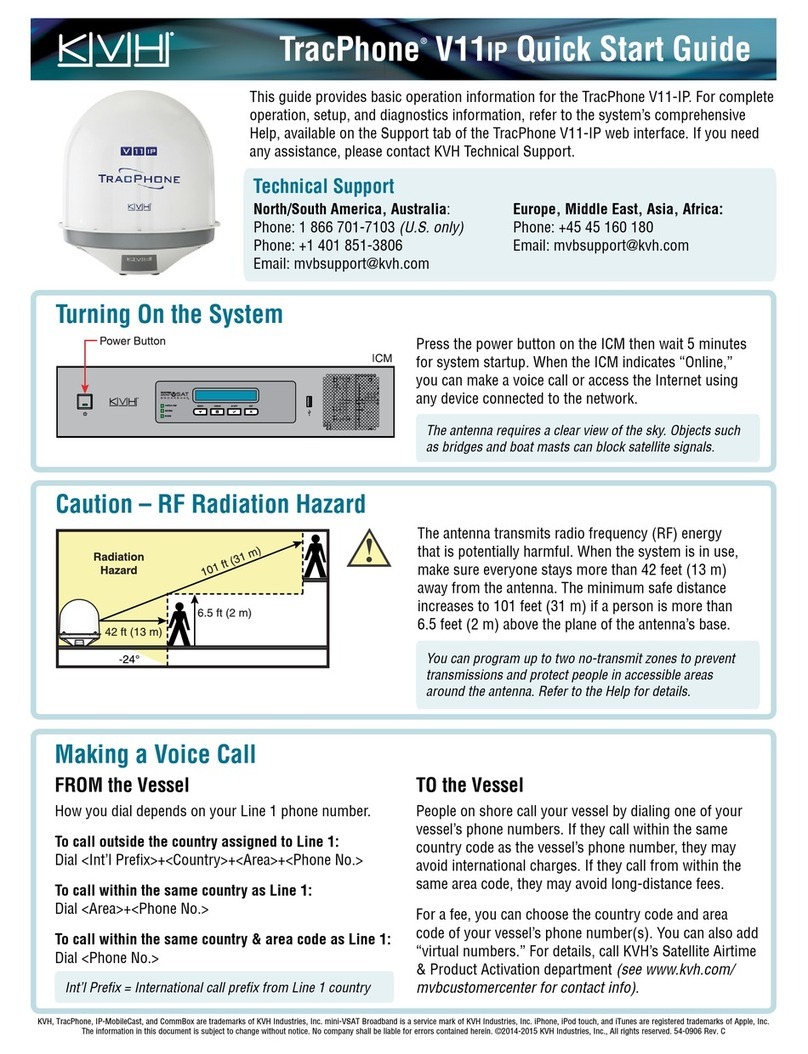

KVH Industries TracPhone V11IP User manual

KVH Industries

KVH Industries TracVision R5SL Guide

KVH Industries

KVH Industries TracVision UHD7 User manual

KVH Industries

KVH Industries TracVision HD7 LNB Guide

KVH Industries

KVH Industries 5616 User manual

Popular Antenna manuals by other brands

Alfa Network

Alfa Network APA-L01 Specifications

Naval

Naval PR-422CA Operation manual

Feig Electronic

Feig Electronic ID ISC.ANTH200/200 Series manual

TERK Technologies

TERK Technologies TV44 owner's manual

Directive Systems & Engineering

Directive Systems & Engineering DSE2324LYRMK quick start guide

HP

HP J8999A instructions

CommScope

CommScope CMAX-OMFX-43M-I53 Installation instruction

Ramsey Electronics

Ramsey Electronics DAP25 Kit assembly and instruction manual

COBHAM

COBHAM SAILOR 800 VSAT Replacement procedure

Trango Systems

Trango Systems AD900-9 Specification sheet

Steren

Steren ANT-100 user manual

IWCS

IWCS iriBelt II Quick start user guide