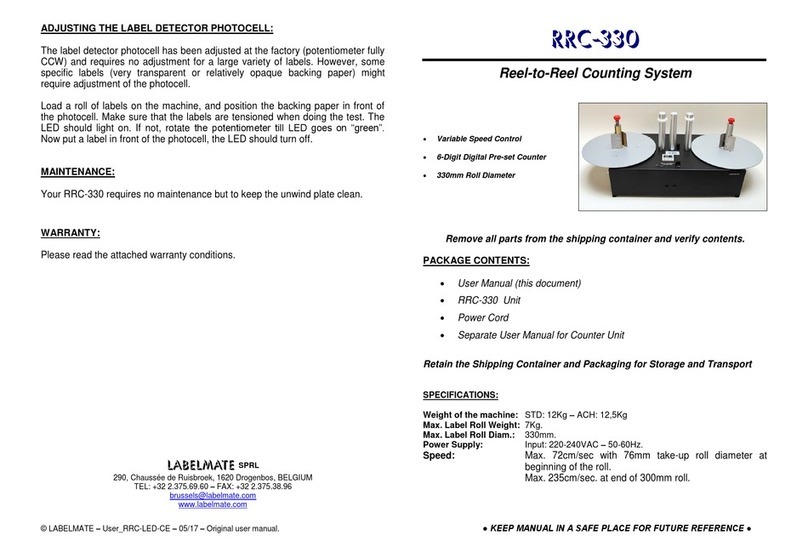

SPECIFICATIONS:

Size: (Overall envelope) HWD – 13”x33”x9” (330x584x229-mm).

Power: Power Supply: 100-240vac 50-60Hz, Output 24vdc, 4.17A.

Roll Width: 6.5” (170-mm). Depending on Roll Diameter.

Core Diameter: RRC-330-US Unwind & Rewind: 3” (76-mm).

RRC-330-USA Unwind: 3” (76-mm), Rewind: 1”-4”

(25-100-mm).

SET-UP:

Plug the Power Supply Output Cable to the Power Jack on the

Rear Panel of the Unit. Plug the Power Supply into a suitable AC Power

Outlet. Rotate the SPEED Control to minimum (full counter-clockwise

position). Place the Power Switch on the rear of the Unit to the “ON / 1”

position.

OPERATION:

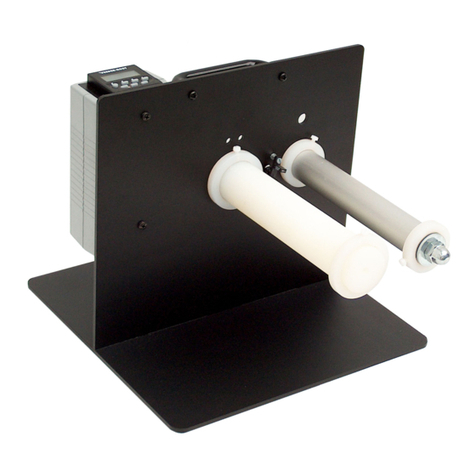

Place the “STOP / RUN” Switch in the STOP Position. Place

your roll of labels on the Supply Roll Spindle on the left side of the unit.

Note that you can “Wind-In” or “Wind-Out” depending on which way you

place the Label Roll on the unit, either right-side-up or upside-down.

Place an empty label core (not included) over the Take-Up

Spindle, thread the labels behind the Guide Rollers and through the

sensors, and secure the Label Web to the empty label core using a piece

of tape. Reset the Counter to zero, and start the unit by switching the

“STOP/RUN” Switch to “RUN”. The machine will stop when out of labels or

when the preset Label Count is reached. To re-start, switch the “STOP/

RUN” Switch to “STOP”. Reload and rethread the unit following the same

procedure as before.

The plastic Ring on the first Rotating Paper Guide can be used if

the supply roll is unevenly wound. Setting the Ring at the proper height will

help correct the unevenness of the Roll on the rewind side. It is

recommended to lower the speed if the supply roll is very uneven.

Select - Ultrasonic (transparent) or Optical (opaque) label count.

SELF-TEACHING ULTRASONIC SENSOR

To begin counting labels, once the labels have been threaded

through the Sensor press and hold the “T” button until the green and

yellow LED’s flash simultaneously. Release the “T” button and advance the

label stock through the sensor until the LED’s stop flashing and only the

green LED is shining. Manually rotate the Supply Roll in a counter-

clockwise direction until the first label you want to count is properly

positioned. Reset the Counter to 0 and start the unit.

WARNING

This product is for indoor use only.

Not for use in wet locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services. IMPORTANT NOTE REGARDING BIDIRECTIONAL REWINDING

The Take-Up Spindle on the right side of the unit can rotate in

either direction depending on the direction selected by the Direction Switch

on the left-hand panel of the unit. DO NOT FLIP THE DIRECTION SWITCH

WHILE THE UNIT IS RUNNING AS THIS MAY IRREPARABLY DAMAGE THE UNIT.

Always stop the unit first before switching the rewind direction.

RRC-330-A ONLY: USING THE ADJUSTABLE CORE HOLDER (ACH):

Unlock the three Locking Levers underneath the take-up Flange by

turning them clockwise. (The Lever Arms may be repositioned if necessary

by pulling straight down and rotating to the desired position.) While holding

the Take-Up Flange, rotate the black plate underneath the Take-Up Flange

to bring the “Fingers” together or spread them apart. Place your Take-Up

Core approximately half way down over the “Fingers” and rotate the black

plate again to bring the “Fingers” in contact with the Core. Lock the

Locking Levers by turning them counter-clockwise. Push the Take-Up

Core all the way down on the “Fingers”. The Core should now be held

tight. If not, redo the foregoing operation.

NOTE:

Keep the Unwind Plate clean of particles and label adhesive.

END-OF-ROLL and/or OPTICAL PHOTOCELL ADJUSTMENT:

The sensitivity of the Photocell that detects the end of Labels

(stops the RRC) should be calibrated for the label web and labels being

counted. Here’s how: Place the RRC STOP / RUN Switch in the STOP

Position. Place a Label Liner ONLY (no label) in the Label Sensor Gap. (1)

Using a small flat-bladed screwdriver, adjust the Photocell Adjust Control

until the green Photocell Adjust LED illuminates. –or– (2) Adjust Photocell

Adjust control for 3- to 5-VDC at the Photocell Test Jack 3.5-mm Plug.

Remove the label liner from the Sensor Gap and observe that the voltage

falls to 0.25VDC or less. Either method yields identical results.

SENSOR SELECT OPTION

Flip the switch on the back of the unit to select OPAQUE - for

opaque labels and opaque backing only, using the photocell sensor OR

select TRANSPARENT - for transparent labels and transparent backing

using the Ultrasonic sensor.

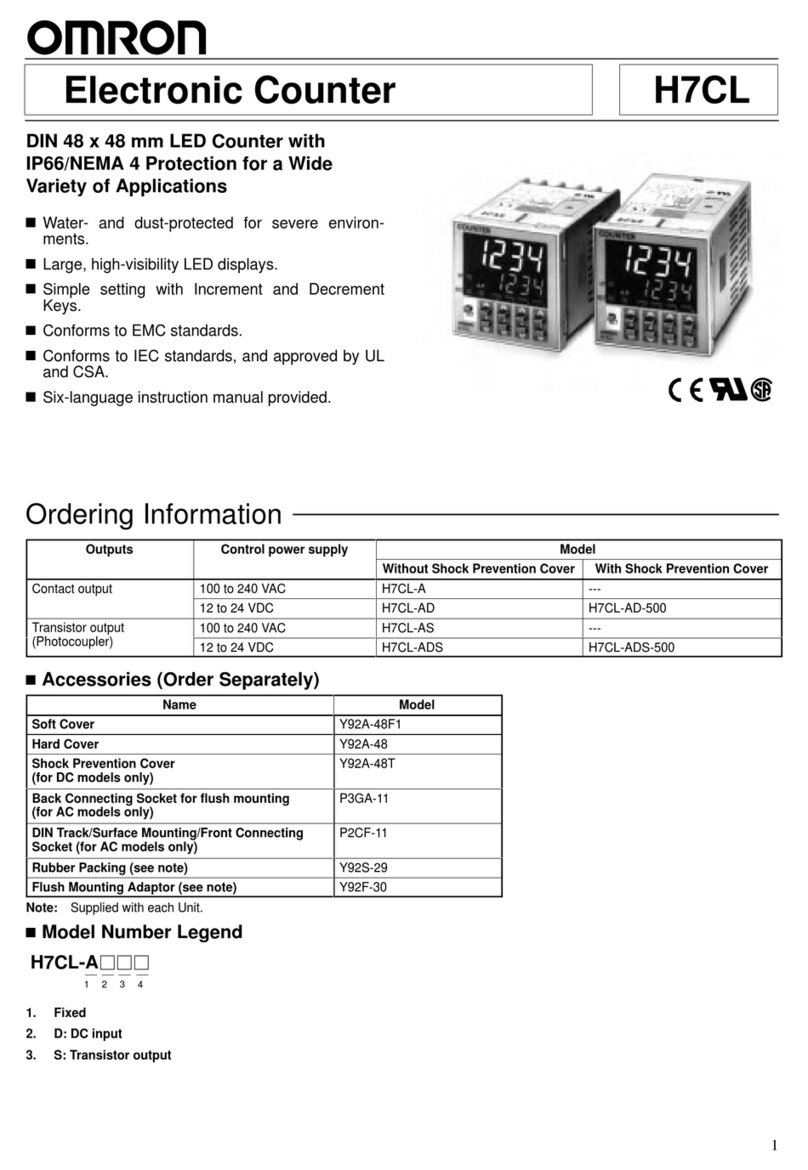

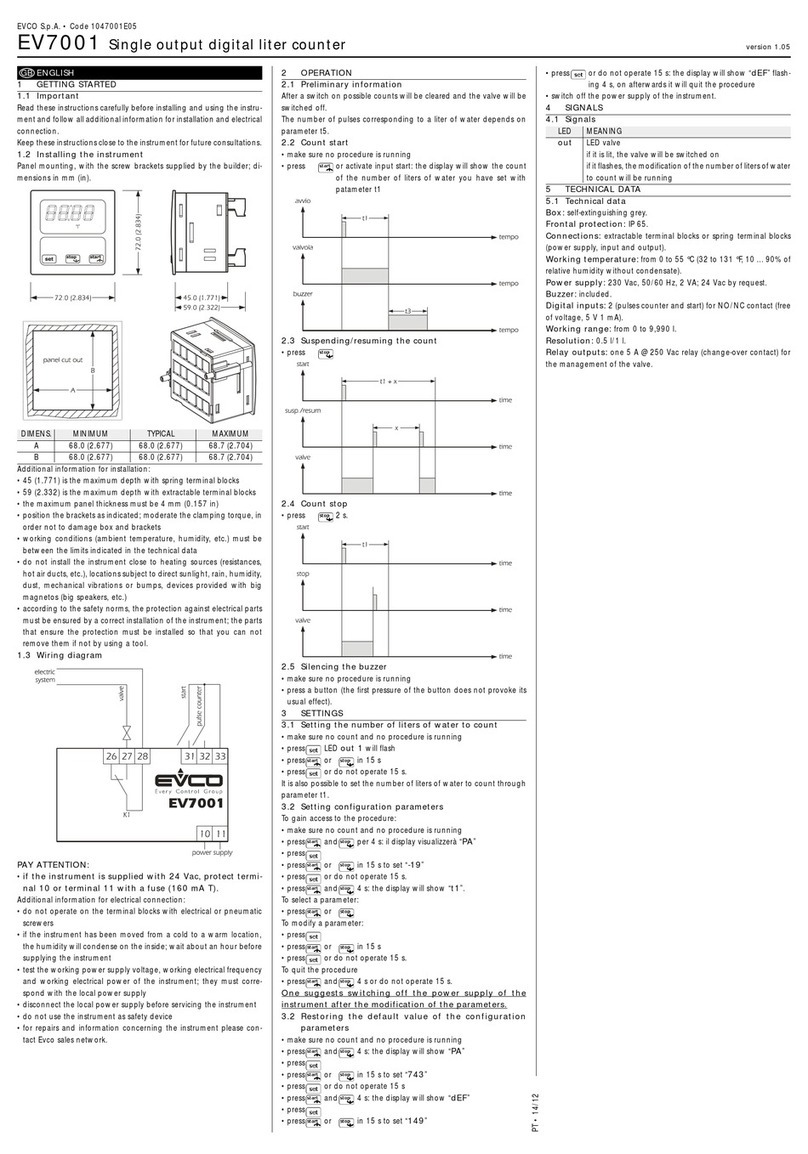

Please refer to the included Counter Specification sheet for details of the

digital Counter operation and to the Sensor Set-up Instruction Sheet for

details of adjusting the Sensor Mode and sensitivity in the event you are

counting difficult labels.

SPECIFICATIONS:

Size: (Overall envelope) HWD – 13”x33”x9” (330x584x229-mm).

Power: Power Supply: 100-240vac 50-60Hz, Output 24vdc, 4.17A.

Roll Width: 6.5” (170-mm). Depending on Roll Diameter.

Core Diameter: RRC-330-US Unwind & Rewind: 3” (76-mm).

RRC-330-USA Unwind: 3” (76-mm), Rewind: 1”-4”

(25-100-mm).

SET-UP:

Plug the Power Supply Output Cable to the Power Jack on the

Rear Panel of the Unit. Plug the Power Supply into a suitable AC Power

Outlet. Rotate the SPEED Control to minimum (full counter-clockwise

position). Place the Power Switch on the rear of the Unit to the “ON / 1”

position.

OPERATION:

Place the “STOP / RUN” Switch in the STOP Position. Place

your roll of labels on the Supply Roll Spindle on the left side of the unit.

Note that you can “Wind-In” or “Wind-Out” depending on which way you

place the Label Roll on the unit, either right-side-up or upside-down.

Place an empty label core (not included) over the Take-Up

Spindle, thread the labels behind the Guide Rollers and through the

sensors, and secure the Label Web to the empty label core using a piece

of tape. Reset the Counter to zero, and start the unit by switching the

“STOP/RUN” Switch to “RUN”. The machine will stop when out of labels or

when the preset Label Count is reached. To re-start, switch the “STOP/

RUN” Switch to “STOP”. Reload and rethread the unit following the same

procedure as before.

The plastic Ring on the first Rotating Paper Guide can be used if

the supply roll is unevenly wound. Setting the Ring at the proper height will

help correct the unevenness of the Roll on the rewind side. It is

recommended to lower the speed if the supply roll is very uneven.

Select - Ultrasonic (transparent) or Optical (opaque) label count.

SELF-TEACHING ULTRASONIC SENSOR

To begin counting labels, once the labels have been threaded

through the Sensor press and hold the “T” button until the green and

yellow LED’s flash simultaneously. Release the “T” button and advance the

label stock through the sensor until the LED’s stop flashing and only the

green LED is shining. Manually rotate the Supply Roll in a counter-

clockwise direction until the first label you want to count is properly

positioned. Reset the Counter to 0 and start the unit.

WARNING

This product is for indoor use only.

Not for use in wet locations.

Unplug unit before removing waste material or

performing any cleaning or maintenance services. IMPORTANT NOTE REGARDING BIDIRECTIONAL REWINDING

The Take-Up Spindle on the right side of the unit can rotate in

either direction depending on the direction selected by the Direction Switch

on the left-hand panel of the unit. DO NOT FLIP THE DIRECTION SWITCH

WHILE THE UNIT IS RUNNING AS THIS MAY IRREPARABLY DAMAGE THE UNIT.

Always stop the unit first before switching the rewind direction.

RRC-330-A ONLY: USING THE ADJUSTABLE CORE HOLDER (ACH):

Unlock the three Locking Levers underneath the take-up Flange by

turning them clockwise. (The Lever Arms may be repositioned if necessary

by pulling straight down and rotating to the desired position.) While holding

the Take-Up Flange, rotate the black plate underneath the Take-Up Flange

to bring the “Fingers” together or spread them apart. Place your Take-Up

Core approximately half way down over the “Fingers” and rotate the black

plate again to bring the “Fingers” in contact with the Core. Lock the

Locking Levers by turning them counter-clockwise. Push the Take-Up

Core all the way down on the “Fingers”. The Core should now be held

tight. If not, redo the foregoing operation.

NOTE:

Keep the Unwind Plate clean of particles and label adhesive.

END-OF-ROLL and/or OPTICAL PHOTOCELL ADJUSTMENT:

The sensitivity of the Photocell that detects the end of Labels

(stops the RRC) should be calibrated for the label web and labels being

counted. Here’s how: Place the RRC STOP / RUN Switch in the STOP

Position. Place a Label Liner ONLY (no label) in the Label Sensor Gap. (1)

Using a small flat-bladed screwdriver, adjust the Photocell Adjust Control

until the green Photocell Adjust LED illuminates. –or– (2) Adjust Photocell

Adjust control for 3- to 5-VDC at the Photocell Test Jack 3.5-mm Plug.

Remove the label liner from the Sensor Gap and observe that the voltage

falls to 0.25VDC or less. Either method yields identical results.

SENSOR SELECT OPTION

Flip the switch on the back of the unit to select OPAQUE - for

opaque labels and opaque backing only, using the photocell sensor OR

select TRANSPARENT - for transparent labels and transparent backing

using the Ultrasonic sensor.

Please refer to the included Counter Specification sheet for details of the

digital Counter operation and to the Sensor Set-up Instruction Sheet for

details of adjusting the Sensor Mode and sensitivity in the event you are

counting difficult labels.