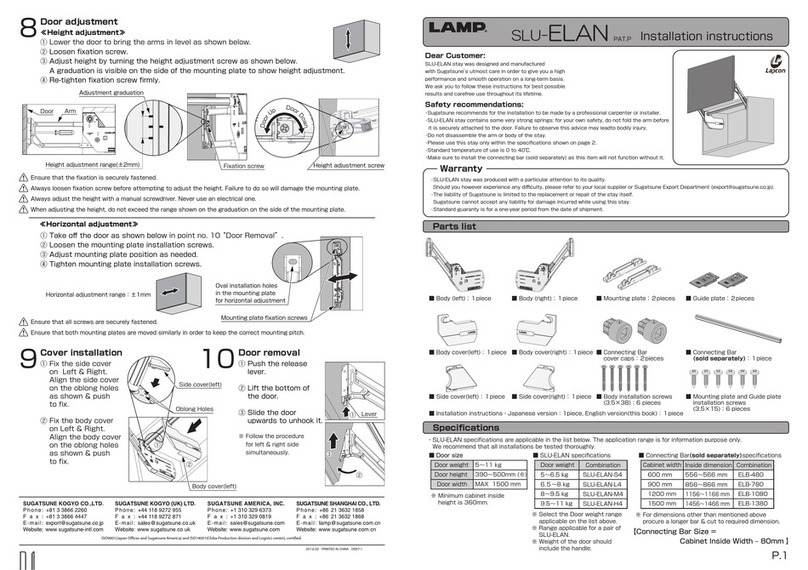

When the door is completely closed, fix the “Support arm L-type

bracket” to the door with the supplied screws.

Fixing support arm

Tighten the fixing screw A, and fix the “Support arm crank

bracket”.

Fixing bracket

Loosen the fixing screw A so that the “Support arm crank

bracket” is slid along the groove of the “Channel rail”.

Loosing bracket

While keeping the door closed with no gap between the door

and cabinet (wooden frame), loosen the “Hexagon socket head

cap screws” fixing the “Pipe clamp” attached to the lower arm,

and retighten them.

If there is any gap, adjust it by referring to the following

instructions on the adjustment and figures on the right side.

Adjusting the gap between cabinet (wooden frame) and door

8 9

When the door position is required to adjust, be sure to loosen the fixing screw A first so that the bracket can be slid.

After adjustment is complete, fix the “Support arm crank bracket”.

●If there is any gap between the “Cabinet” and the upper side

of the door, be sure to loosen the fixing screw A at first, and

tighten the “Door close positioning screw C”. Then, retighten

the fixing screw A for re-adjustment.

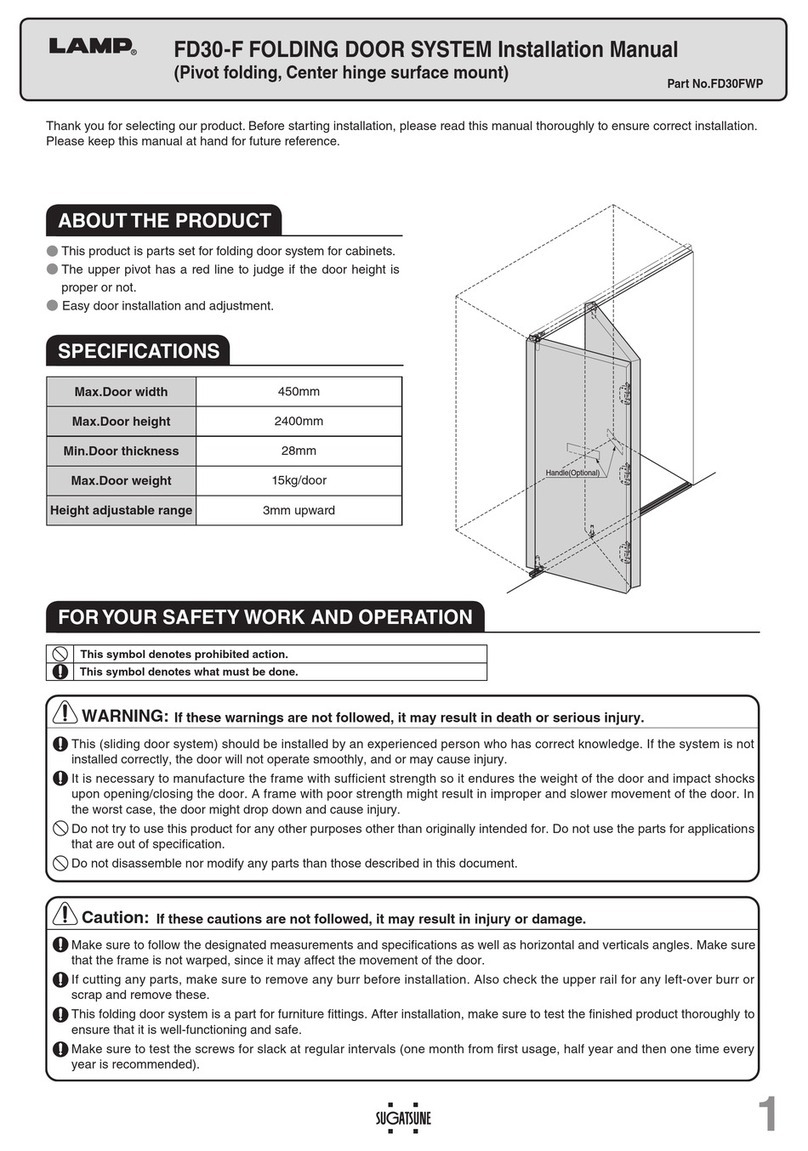

Connect the upper and lower arms to the “Positioning unit”.

Insert hexagon head bolt with flat washer, then screw it by

hexagon nut.

Connecting upper and lower arms to positioning unit

Hexagon head bolt for connecting

Flat washer

Arm

Positioning unit

Self-tapping screw

Hexagon nut

Adjust the vertical and horizontal positions after closing the

door completely.

Horizontal adjusting: Turn the screw A of the “Door positioning unit”

clockwise. Then, the door is moved leftward

when it is seen from the back of the door. It is

moved rightward when the screw A is turned

counterclockwise.

Vertical adjusting: Turn the connecting hexagon head bolt clockwise.

Then, the door is raised. It can be lowered

when it is turned counterclockwise.

Vertical and horizontal positioning of door

Turn clockwise

Adjustment of door

Turn clockwise

Connecting hexagon head bolt Arm

Door Horizontal adjustment

Door

Vertical adjustment

Door positioning unit

Tighten this hexagon nut after

vertical adjustment is complete.

When performing horizontal

adjustment, turn them once

to slacken them.

After adjustment is complete,

tighten them.

Screw A

Gap is not allowed

●If there is any gap between the “Cabinet” and the lower side

of the door, adjust the upper “Door close positioning screw B”

in a similar manner to the above.

Bottom of roof

Back of door

Support arm crank bracket

Channel rail

Fixing screw A

Support arm L-type bracket

Upper arm

Arm connecting pipe

Door close position

adjuster screw B, C

B

C

Fixing screw A

Lower arm

Hexagon socket head

cap screw

Arm connecting pipe

Pipe clamp

For both the upper and lower arms, gap should not be allowed between

the head of the hexagon head bolt and the flat washer. If there is any gap,

turn the hexagon head bolt clockwise to eliminate the gap so that the

weight of the door is received by the upper and lower arms uniformly.

CAUTION