Lanier R/C

8. Mount the tail wheel using 3-#4 x ½” sheet metal

screws. Use the first three holes in the mount.

9. Mount the tail wheel on the center of the fuselage

flush with the back edge. Hold in place and drill three 1/16”

holes through three holes in the mount. Drive in the screws

and tighten them.

10. Locate the spring and cut off excess wire, 1-1/4” from

spring, on the long end. Now bend a ¼”leg at 90 degree on

that end. Place the opposite end in the small hole on the

brassfitting at top of bearing shaft. Note where ¼” leg ends

onbottomofrudder. Markanddrilla1/16”hole. Note:make

sure the wheel is properly aligned before drill-ing the hole.

Harden the hole with thin CA. Insert the ¼” leg in the hole,

insert a #4 x ½” sheet metal screw in the same hole and

tighten. Do not over tighten and strip the threads. Use a

drop of thin CA to secure the screw.

11. Prepare the servos with the proper servo arm for the

rudder and elevators. Mount them in the servo wells with

#2x½” sheetmetal screws(not supplied) Locatethe short

pushrodsfor theelevatorsand cut 3/8”off both endsof each

one. ADremelcut-offwheelworksfinehere. Mounta#4hex

nut on the end ofeachpushrod. Nowmounta4-40clevis on

the ends of each..

12. Center the servo and elevator. Tape the elevator at

the tip so that it will not move. Adjust the clevises on the

pushrodtofitandhookuptoservoarmandcontrolhorn. Slip

on thesafetyclipsandtightenthehexnutsagainsttheclevis.

13. The rudder pushrod is the proper length. Assemble in

thesamemannerasdescribedabove. Note: We recommendNote: We recommend

you use two servos on the rudder, the two pushrods will actyou use two servos on the rudder, the two pushrods will act

asapullasapull--pullsetuppropullsetupprovidingmaximumforcewithnoflexingofvidingmaximumforcewithnoflexingof

the pushrods..the pushrods..

14. When using two servos on the elevators, it is necessaryWhen using two servos on the elevators, it is necessary

to use a “Y” connector with a servo reverser in one of theto use a “Y” connector with a servo reverser in one of the

“Y’s”thereby allowingbothservostobemountedinthesame“Y’s”therebyallowingbothservostobemountedinthe same

position. Maxx Productsposition. Maxx Products International (see notes) hasoneInternational(see notes)has one

withan internalpotsoadjustmentcanbemadeelectricallytowithaninternalpotsoadjustment canbemadeelectrically to

one elevator. Their “Y” connector, called the Miracle “Y”one elevator. Their “Y” connector, called the Miracle “Y”

Connector,has extra long leads.Of course withanexpensiveConnector,has extra long leads.Of course withanexpensive

computerradio youcan always connectcomputerradio youcan always connect the elevators in twothe elevators in two

differentchannelstherebyeliminatingtheneedfortheMiracledifferentchannelstherebyeliminatingtheneedfortheMiracle

“Y” Connector. However, you will need servo lead extensions.“Y” Connector. However, you will need servo lead extensions.

The rudder with two servos will then need a plain “Y”The rudder with two servos will then need a plain “Y”

connector and a servo lead extension.connector and a servo lead extension.

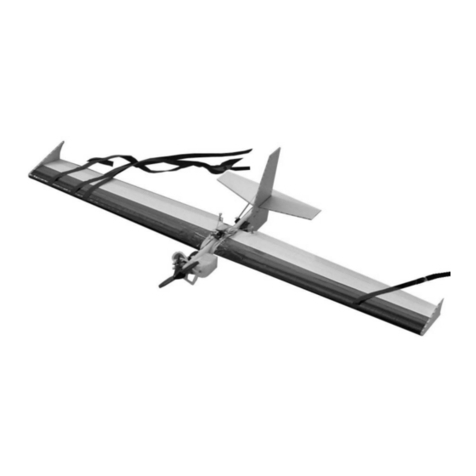

MOUNTING THEMOUNTING THE LANDING GEARLANDING GEAR