Technical support maintenance manual

Rel. 0.00 / February 2020 1

1. GENERAL INFORMATION OF MANUAL

1.1. STRUCTURE OF MANUAL

Before performing any operation on the machine, the

maintenance technician must carefully read the instruc-

tions provided in this publication. No operation must be

performed before having read and properly understood

the contents of this manual. If in doubt as to how to cor-

rectly interpret the instructions, contact Lavazza S.p.A.

for clarications thereof.

1.1.1. SCOPE AND CONTENTS

This manual contains the information required for cor-

rect maintenance of the machine, as well as safety in-

structions, troubleshooting and diagrams. This manual

does not replace the Installation Manual supplied with

the machine.

All reproduction rights of this manual are reserved to

Luigi Lavazza S.p.A. (hereinafter Lavazza).

Any reproduction of the text and illustrations, even

partial, is prohibited. The information herein cannot be

disclosed to third parties without the written consent of

Lavazza which has exclusive property thereof.

Lavazza reserves the right of modifying the features of

the appliance dealt with in this manual without prior no-

tice. Furthermore it will not be held liable for any inac-

curacies attributable to printing errors and/or the con-

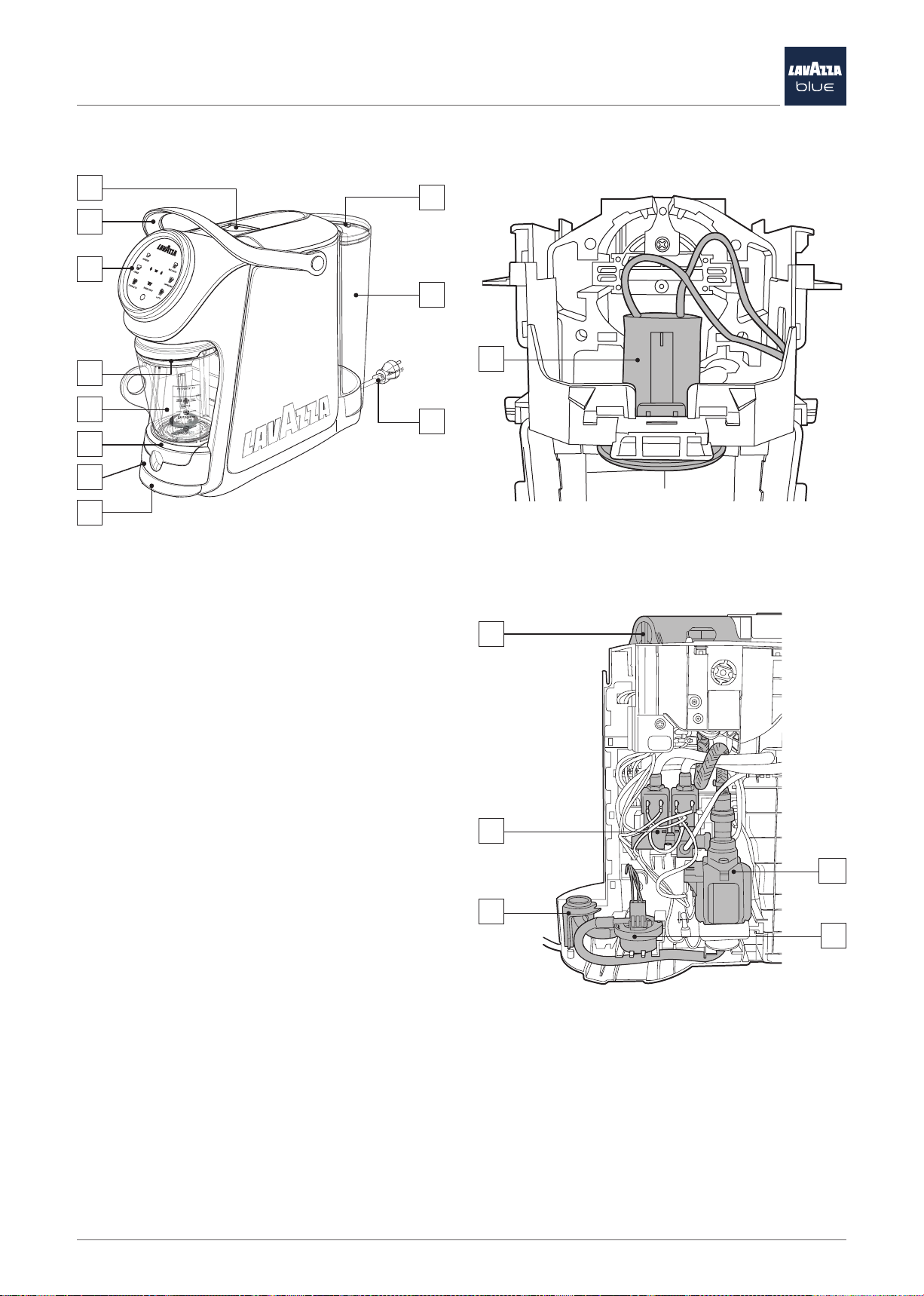

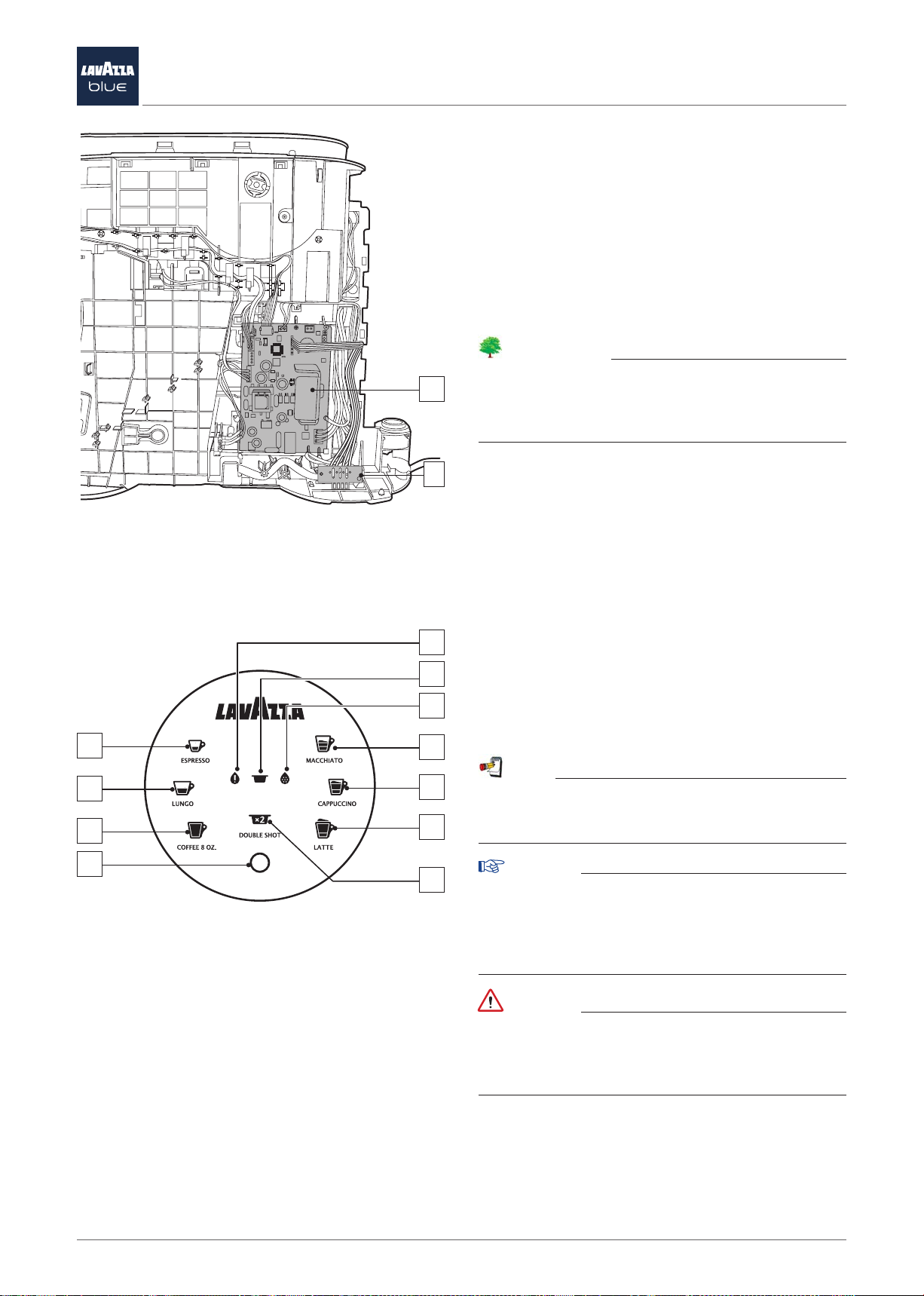

tents in it. Furthermore Lavazza informs that the images

or photographs of the machine included in this manual

have purely representative purposes and could undergo

changes without prior notice.

Check the Lavazza Technical Service website (at

https://ts.lavazza.com) to make sure you have the most

recent version available of this manual. If not, you may

download a more recent copy. We also suggest that you

consult further documentation on the machine, such as

Software, Quick Guide, Technical News, if provided on

the Lavazza Technical Service website.

1.1.2. MESSAGES USED

Attention

ATTENTION messages indicate even high risk

danger for the technician. The operations described

after this message must be carried out with the

utmost attention and in maximum safety, using

personal protective equipment.

Warning

WARNING messages are displayed before

procedures which could cause damage to the

machine if not complied with.

Environment

ENVIRONMENT messages are displayed before

procedures which could harm the environment if

not complied with.

Note

NOTE messages highlight further indications useful

for the maintenance technician.

1.1.3. ADDRESSEES AND QUALIFIED PERSONNEL

This manual is intended for technicians qualied to per-

form maintenance on the machine. Lavazza will not be

held liable for damage resulting from failure to comply

with this indication.

The machine can only be serviced by the technician

who, having read this manual:

- has specific experience in maintenance of profession-

al coffee machines;

- is capable of repairing the malfunctions of the ma-

chine/machines dealt with in this manual;

- has understood the technical contents, can correctly

interpret drawings and diagrams and has memorised

the safety information provided below;

- knows the main hygienic, accident-prevention, tech-

nological and safety standards;

- knows what to do in case of an emergency, where to

find the personal protective equipment and how to use

it correctly.

1.1.4. STORING THE MANUAL

In order to keep this manual intact over time, it is recom-

mended to:

- use it without damaging its contents in whole or in

part;

- refrain from removing, tearing or rewriting parts of the

manual for any reason whatsoever;

- keep the manual in a place protected against moisture

and heat, to avoid endangering the quality of the pub-

lication and legibility of all its parts;

- make the manual accessible for all maintenance per-

sonnel.

Warning

Should the manual be damaged or lost, you may

download a copy of it from the website Lavazza

Technical Service at https://ts.lavazza.com.