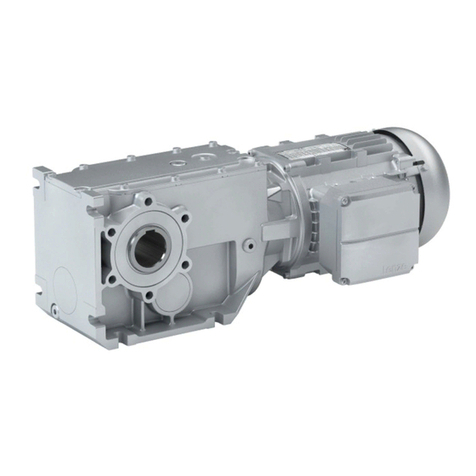

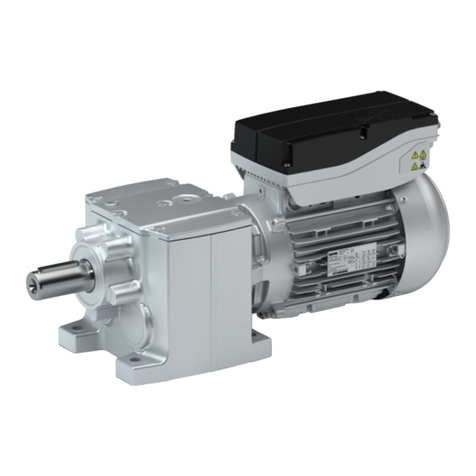

The modular system

Values printed in bold are standard designs. Values that are not printed in bold

are potenal extensions, some of them including a surcharge.

Geared motors up to 450 Nm

Gearbox g500-B110 g500-B240 g500-B450

Min. motor assignment m850-S120 m850-S120 m850-S120

Max. motor assignment m850-S120 m850-S140 m850-S140

Technical data

Max. output torque Nm 100 140 210

Min. drive torque Nm 4.8 4.8 4.8

Max. drive torque Nm 7.4 14.0 17.4

Mounng posion

Standard M1, M2, M3, M4, M5, M6 (ABCDEF)

Combined M1/5/6 (AEF)

Color Primed

Painted in RAL colors

Surface and corrosion protecon OKS-G

Dierent types of OKS

Output sha

Solid sha with featherkey (V) mm 20 x 40 30 x 60 30 x 60

Hollow sha with keyway (H) mm 20/25 30/35 35/40

Hollow sha with shrink disc (S) mm 20 30/35 35

Sha material Steel

Stainless steel

Sha sealing ring material NBR

FKM (Viton)

Output sha bearing Normal

Reinforced

Gearbox version With foot (HBR)/(VBR/SBR)

With foot and centring (HAR/VAR/SAR)

With foot and output ange (HAK/VAK/SAK)

Output ange (K) mm 120/160 160/200 200

Lubricant Synthec oil

Food-compable oil

Venlaon Without Vent valve

Cooling Self-venlated

Torque plate At threaded pitch circle

On the housing foot

Sha cover Hollow sha cover, hoseproof

Shrink disc cover

Motor connecon Connector

ICN hybrid connector for One Cable Technology (OCT)

Permanent magnet holding brake Without

With

Feedback

Without funconal safety Resolver

Absolute value encoder

Digital absolute value encoder for One Cable Technology (OCT)

With funconal safety Resolver

Absolute value encoder

Digital absolute value encoder for One Cable Technology (OCT)

Temperature monitoring PT1000 temperature sensor

Product informaon

The modular system

10