Lenze M Series User manual

Other Lenze Engine manuals

Lenze

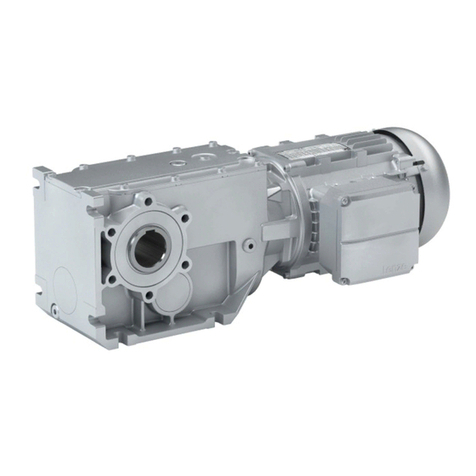

Lenze g500-S Guide

Lenze

Lenze m850 Technical manual

Lenze

Lenze 13.120.35 Quick start guide

Lenze

Lenze M Series User manual

Lenze

Lenze MQA Guide

Lenze

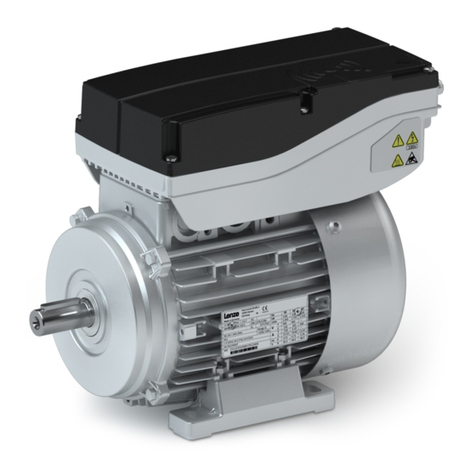

Lenze Smart Motor m300 User manual

Lenze

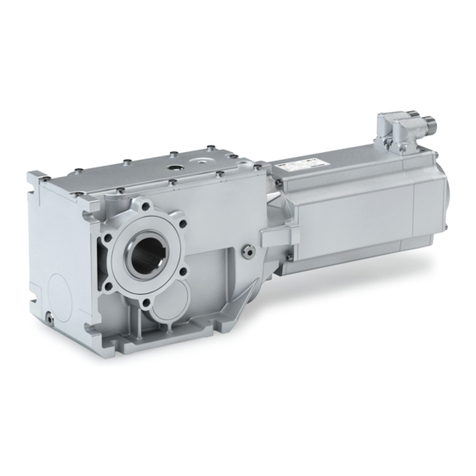

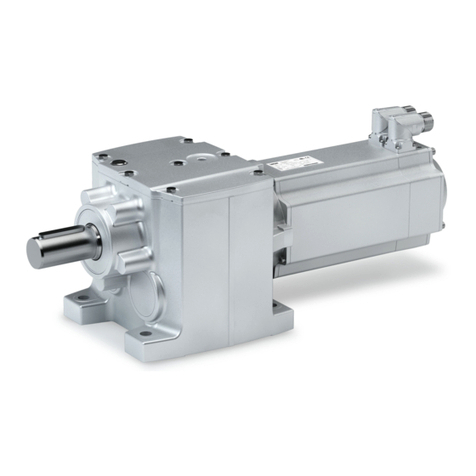

Lenze g500-B Technical manual

Lenze

Lenze g500-B Guide

Lenze

Lenze g500-H45 Technical manual

Lenze

Lenze g500-H Technical manual

Lenze

Lenze g500 Series User manual

Lenze

Lenze MSEMA 080-32 Series Guide

Lenze

Lenze Smart Motor m300 Technical manual

Lenze

Lenze M55BH063S04 Guide

Lenze

Lenze g500-B / m850 Guide

Lenze

Lenze g500-S Guide

Lenze

Lenze MCA Series Guide

Lenze

Lenze IE3 g500-B Technical manual

Lenze

Lenze M Series Operating instructions

Lenze

Lenze g500 Series User guide