Lincat OE7503 User guide

Other Lincat Kitchen Appliance manuals

Lincat

Lincat Lynx Owner's manual

Lincat

Lincat Lynx 400 Operating instructions

Lincat

Lincat Silverlink 600 CS4 Owner's manual

Lincat

Lincat PO49X User manual

Lincat

Lincat PO425/FS Operating instructions

Lincat

Lincat PO425 Owner's manual

Lincat

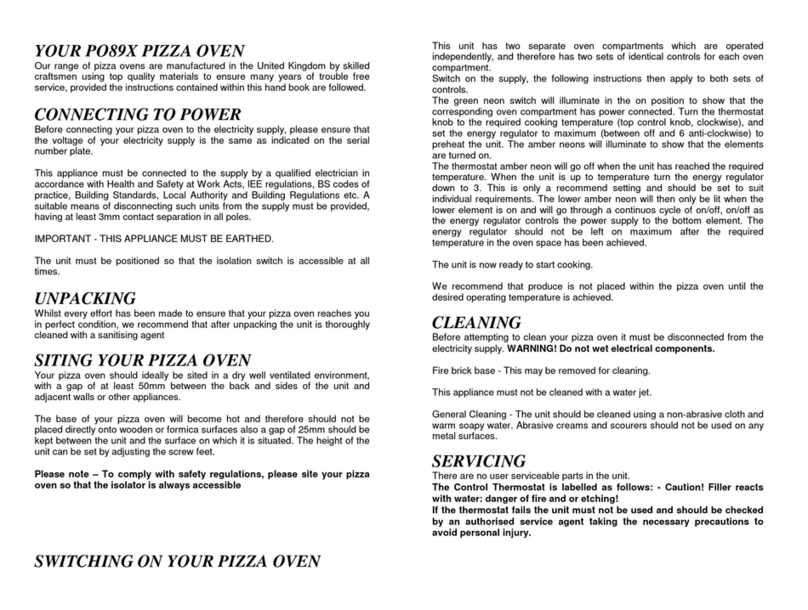

Lincat PO89X Installation instructions

Lincat

Lincat OG8801 Operation manual

Lincat

Lincat PO89X Owner's manual

Lincat

Lincat Lunx 400 LPO Guide

Popular Kitchen Appliance manuals by other brands

Tayama

Tayama TYG-35AF instruction manual

AEG

AEG 43172V-MN user manual

REBER

REBER Professional 40 Use and maintenance

North American

North American BB12482G / TR-F-04-B-NCT-1 Assembly and operating instructions

Presto

Presto fountain popper instruction manual

Westmark

Westmark 1035 2260 operating instructions