Page

Section - E35 - 42D

Form 403240

August 2002

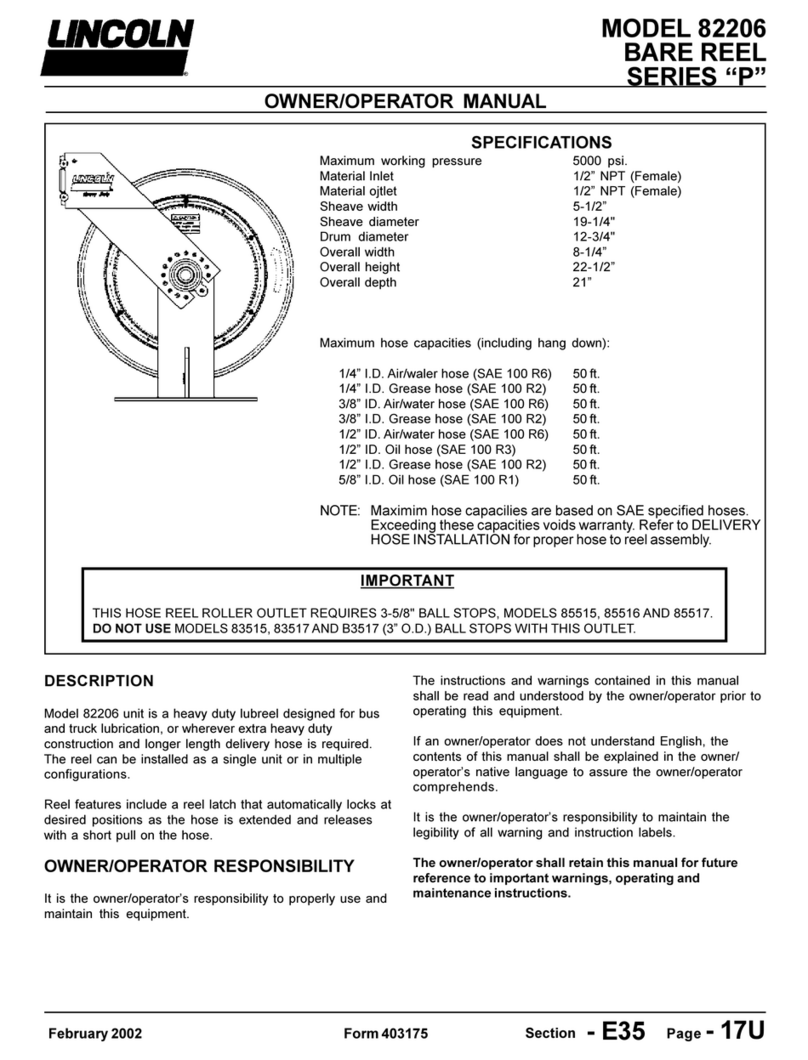

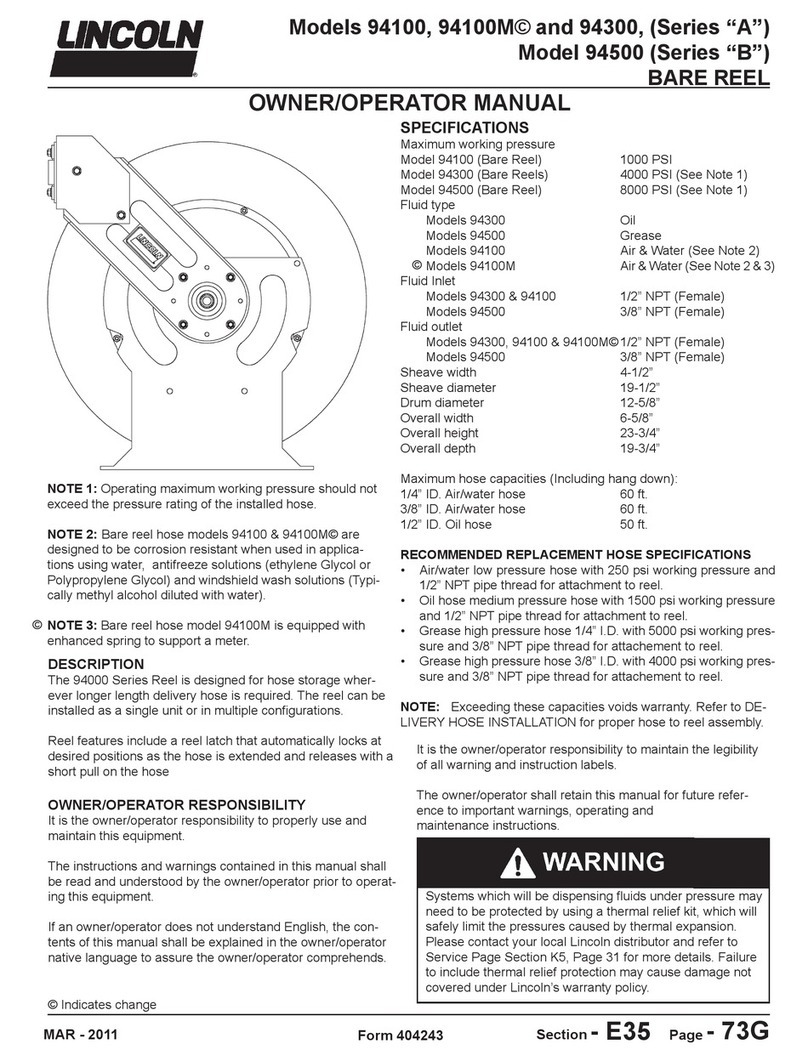

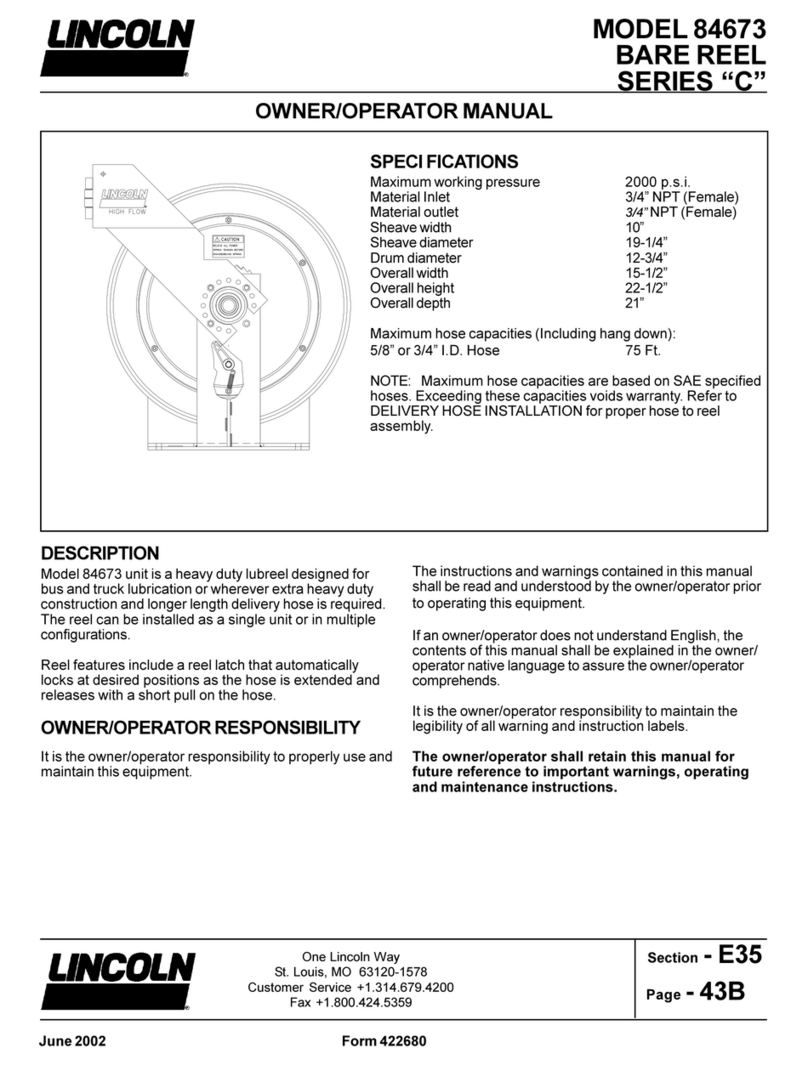

SPECIFICATIONS

Maximum working pressure 2000 p.s.i.

Material Inlet 3/4" NPT (Female

Material outlet 3/4" NPT (Female

Sheave width 5-1/2"

Sheave diameter 19-1/4"

Drum diameter 12-3/4"

Overall width 10"

Overall height 22-1/2"

Overall depth 21"

DESCRIPTION

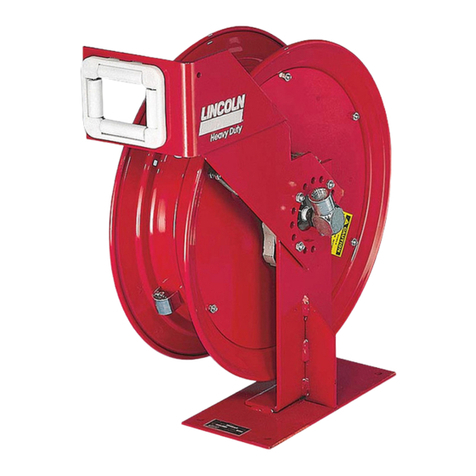

The Model 84672 high floow hose reel is a spring operated

unit designed to hold and retract upto 50 feet of 1/2 diameter

hose. Larger hose diameters can be used with reduced hose

length, see maximum hose capacity chart on page 2.

The reel is a heavy duty unit and designed for bus and truck

lubrication or wherever extra heavy duty construction and long-

er length delivery hose is required. The reel can be installed

as a single unit or in multiple configurations.

Reel features include a reel latch that automatically locks at

desired positions as the hose is extended and releases with

a short pull on the hose.

OWNER/OPERATOR RESPONSIBILITY

It is the owner/operator responsibility to properly use and

maintain this equipment.

The instructions and warnings contained in this manual

shall be read and understood by the owner/operator prior to

operating this equipment.

If an owner/operator does not understand English, the

contents of this manual shall be explained in the owner/

operator native language to assure the owner/operator

comprehends.

It is the owner/operator responsibility to maintain the

legibility of all warning and instruction labels.

The owner/operator shall retain this manual for future

reference to Important warnings, operating and mainte-

nance Instructions.

Failure to heed the following warnings including misuse,

over pressurizing, modifying parts, using incompatible

chemicals and fluids, or using worn or damaged parts,

may result in equipment damage and/or serious person-

al in ury, fire, explosion, or property damage.

Do not exceed the stated maximum working pressure of

the reel or of the lowest rated component in your system.

Do not alter or modify any part of this equipment.

Do not operate this equipment with combustible gas.

Do not attempt to repair or disassemble the equipment

while the system Is pressurized.

Make sure all fluid connections are securely tightened

before using this equipment.

Always read and follow the fluid manufacturers recom-

mendations regarding fluid compatibility, and the use of

protective clothing and equipment.

Check all equipment regularly and repair or replace worn

or damaged parts immediately.

Never point the dispensing valve at any part of the body or

at another person.

Never try to stop or deflect material from dispensing valve

or leading connection or component with your hand or

body.

Always check equipment for proper operation before each

use, making sure safety devices are in place and operat-

ing properly.

Always follow the pressure relief procedure after shutting

off the pump, when checking or servicing any part of the

system, and when installing, cleaning or changing any

part of the system.

Model 84672

BARE HOSE REEL

Series B