SWG OPERATOR INSTALLATION GUIDE

- 3 -

Read the following before beginning to install Linear swing

gate operators:

1. Read the orange “Safety Instructions” brochure enclosed

with the packet of information. If you do not have one,

please call Linear at 1-800-421-1587 to request one.

Read and follow all instructions.

2. All electrical connections to the power supply must be

made by a licensed electrician and must observe all

national and local electrical codes.

3. A separate power-disconnect switch should be located

near the operator so that primary power can be turned

off when necessary.

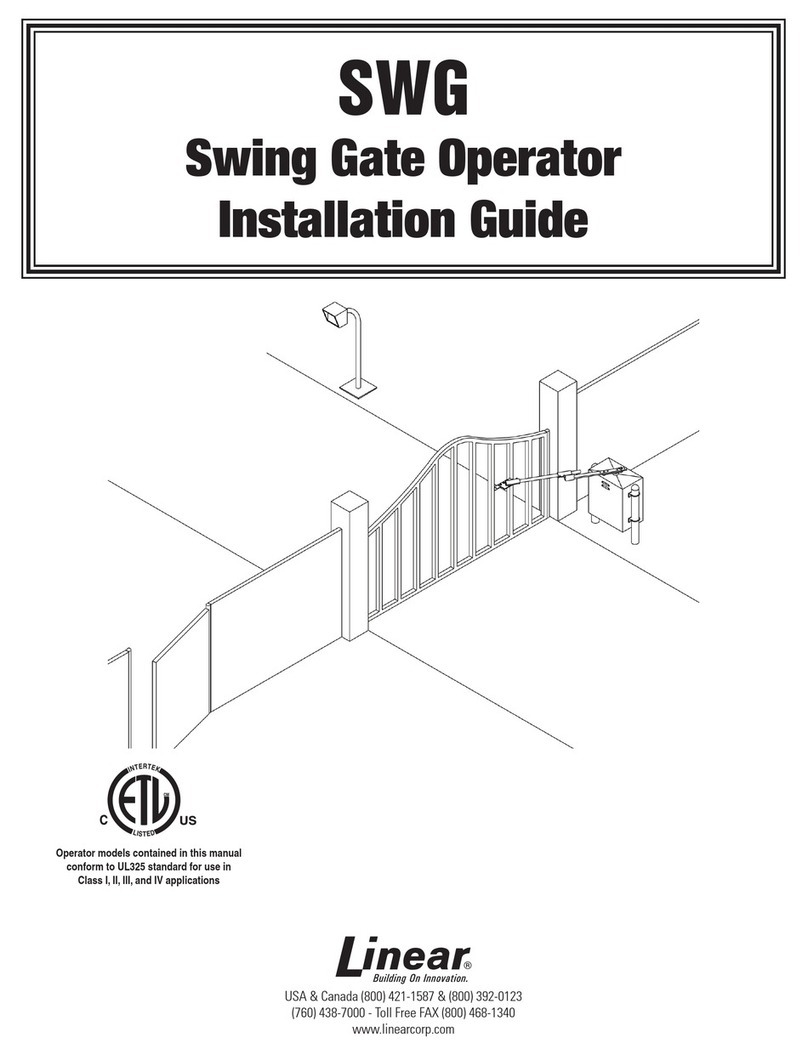

4. A minimum of two (2) WARNING SIGNS shall be in-

stalled, one on each side of the gate where easily visible.

5. Never reach between, through or around the fence to

operate the gate.

6. You must install all required safety equipment.

GATE OPERATOR

CLASSIFICATIONS

All gate operators can be divided into one of four different

classifications, depending on their design and usage.

Class I Residential Vehicular Gate Operator

A vehicular gate operator intended for use in a home of one

to four single family dwellings, or garage or parking area

associated with these dwellings.

Class II Commercial / General Access Vehicular Gate

Operator

A vehicular gate operator intended for use in a commercial

location or building such as a multifamily housing unit of five

or more single family units, hotel, retail store or other building

servicing the general public.

Class III Industrial / Limited Access Vehicular Gate

Operator

A vehicular gate operator intended for use in an industrial

location or building such as a factory or loading dock area

or other location not intended to service the general public.

Class IV Restricted Access Vehicular Gate Operator

A vehicular gate operator intended for use in a guarded in-

dustrial location or building such as an airport security area

or other restricted access locations not servicing the general

public, in which unauthorized access is prevented via supervi-

sion by security personnel.

PRE-INSTALLATION

INFORMATION

Before unpacking, inspect the carton for exterior damage.

If you find damage, advise the delivery carrier of a potential

claim.

Inspect your package carefully. You can check your

accessory box parts with the enclosed packing slip for your

convenience. Claims for shortages will be honored for only

30 days from the date of shipment.

Before installing the operator, read this manual completely

to ensure all requirements for proper installation are pres-

ent. Verify that the voltage to be used matches the voltage

of the operator.

SAFETY INFORMATION

AND WARNINGS

IMPORTANT!!

Before installing the gate operator, make sure the gate’s

swing is free and level throughout the entire swing path. If

the gate does not seem to operate properly, it may affect

the operator performance or greatly shorten the life of the

unit. The gate should be designed so that airflow is ample

to prevent wind resistance and drag.

The following contact or non-contact obstruction

detection devices have been approved for use

with Linear slide gate operators as part of a UL325

compliant installation:

Contact Edges:

Miller Models*: MG0-20, MGR-20, MGS-20, and ME-120

Photoeyes:

2520-441 MMTC Model IR-55 photoeye, 165’ with

mounting hardware

2520-031 MMTC Model E3K photoeye, 28’ with

mounting hardware

*for Linear part numbers, contact a sales representative for details