VS-GSLG OPERATOR INSTALLATION GUIDE

- 2 -

TABLE OF CONTENTS

PRE-INSTALLATION INFORMATION

Gate Operator Classifications........................................................................................................................................................................................................ 3

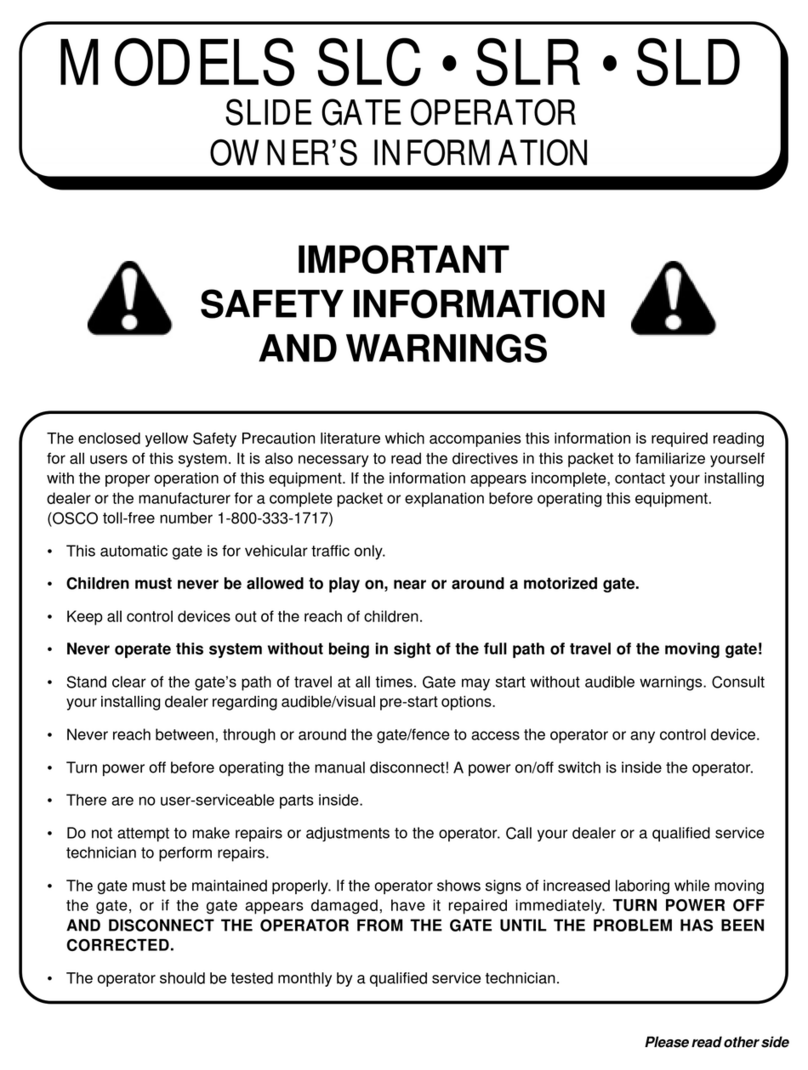

Safety Information and Warnings................................................................................................................................................................................................... 3

Pre-Installation Information............................................................................................................................................................................................................ 3

INSTALLATION

Unpacking and Inspection ............................................................................................................................................................................................................. 4

Pre-Installation Information............................................................................................................................................................................................................ 4

Installation Instructions .................................................................................................................................................................................................................. 4

Electrical Instructions and LImit Switch Adjustments .................................................................................................................................................................... 5

Installation Instructions Drawing.................................................................................................................................................................................................... 6

Four Switch Rotary Limit Box Photo.............................................................................................................................................................................................. 7

Torque Limiter Adjustment............................................................................................................................................................................................................. 8

Manual Disconnect ........................................................................................................................................................................................................................ 8

Maintenance .................................................................................................................................................................................................................................. 9

CONTROL BOARD ADJUSTMENTS and ACCESSORY CONNECTIONS

Control Board Adjustments.......................................................................................................................................................................................................... 10

Terminal Connection Descriptions............................................................................................................................................................................................... 11

Current Sensing Adjustments...................................................................................................................................................................................................... 12

Close Direction Current Sense Adjustment ................................................................................................................................................................................. 12

Open Direction Current Sense Adjustment.................................................................................................................................................................................. 12

Maximum Run Timer Adjustment................................................................................................................................................................................................. 12

Auto Close Timer Adjustment ...................................................................................................................................................................................................... 12

Master/Slave Connection............................................................................................................................................................................................................. 12

Onboard L.E.D. Indicator Descriptions......................................................................................................................................................................................... 13

Important Notes for Installation of Master/Slave Applications ..................................................................................................................................................... 14

Surge Protector Instructions ........................................................................................................................................................................................................ 14

Control and Accessory Connection Illustrations .....................................................................................................................................................................15-18

ILLUSTRATIONS

Loop Layout Illustration................................................................................................................................................................................................................ 19

Edge Layout Illustration #1 .......................................................................................................................................................................................................... 20

Edge Layout Illustration #2 .......................................................................................................................................................................................................... 21

Photo Eye Illustration................................................................................................................................................................................................................... 22

Picket Gate Illustration................................................................................................................................................................................................................. 23

Track Gate Illustration .................................................................................................................................................................................................................. 24

TROUBLESHOOTING ..................................................................................................................................................................................................................... 25

PARTS LISTS

How to Order Replacement Parts................................................................................................................................................................................................ 25

Model VS-GSLG Mechanical Parts Exploded View ..................................................................................................................................................................... 26

Model VS-GSLG Mechanical Parts List ....................................................................................................................................................................................... 27

Model VS-GSLG Control Box Exploded View and Parts List - AC Tech ...................................................................................................................................... 28

Programming Instructions for Variable Speed Drive - AC Tech.................................................................................................................................................... 29

Model VS-GSLG Control Box Exploded View and Parts List - Hitachi......................................................................................................................................... 30

Programming Instructions for Variable Speed Drive - Hitachi...................................................................................................................................................... 31

Wiring Specifications ................................................................................................................................................................................................................... 32

PREVENTATIVE MAINTENANCE ................................................................................................................................................................................................... 34

GATE OPERATOR INSTALLATION CHECKLIST ........................................................................................................................................................................... 36

CAUTION!

DO NOT INSTALL

CONTROLS ON A

GATE OR FENCE LINE

CAUTION!

ONLY QUALIFIED SERVICE

TECHNICIANS SHOULD

WORK ON A LINEAR

SLIDE GATE OPERATOR

CAUTION!

DO NOT INSTALL

CONTROLS

ON THE OPERATOR