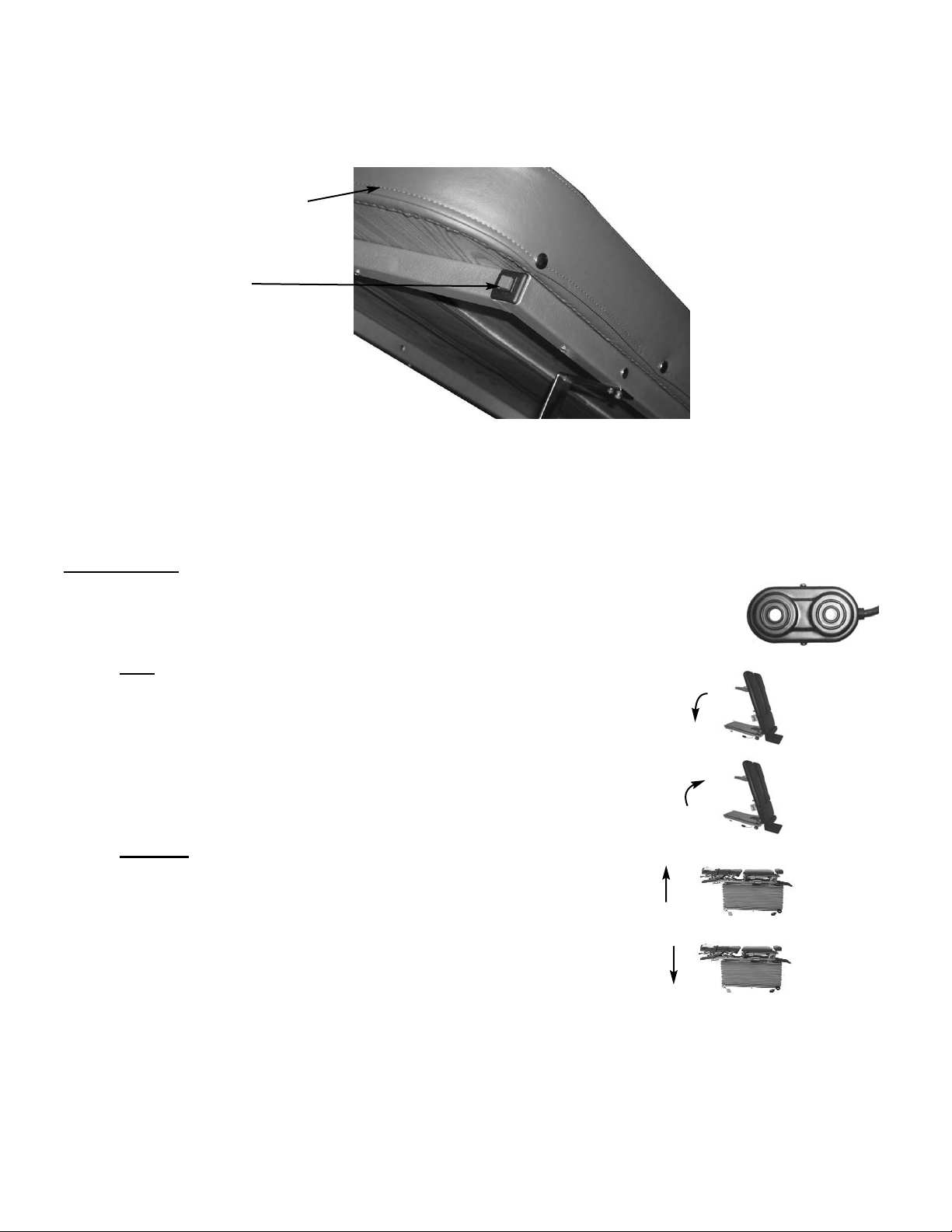

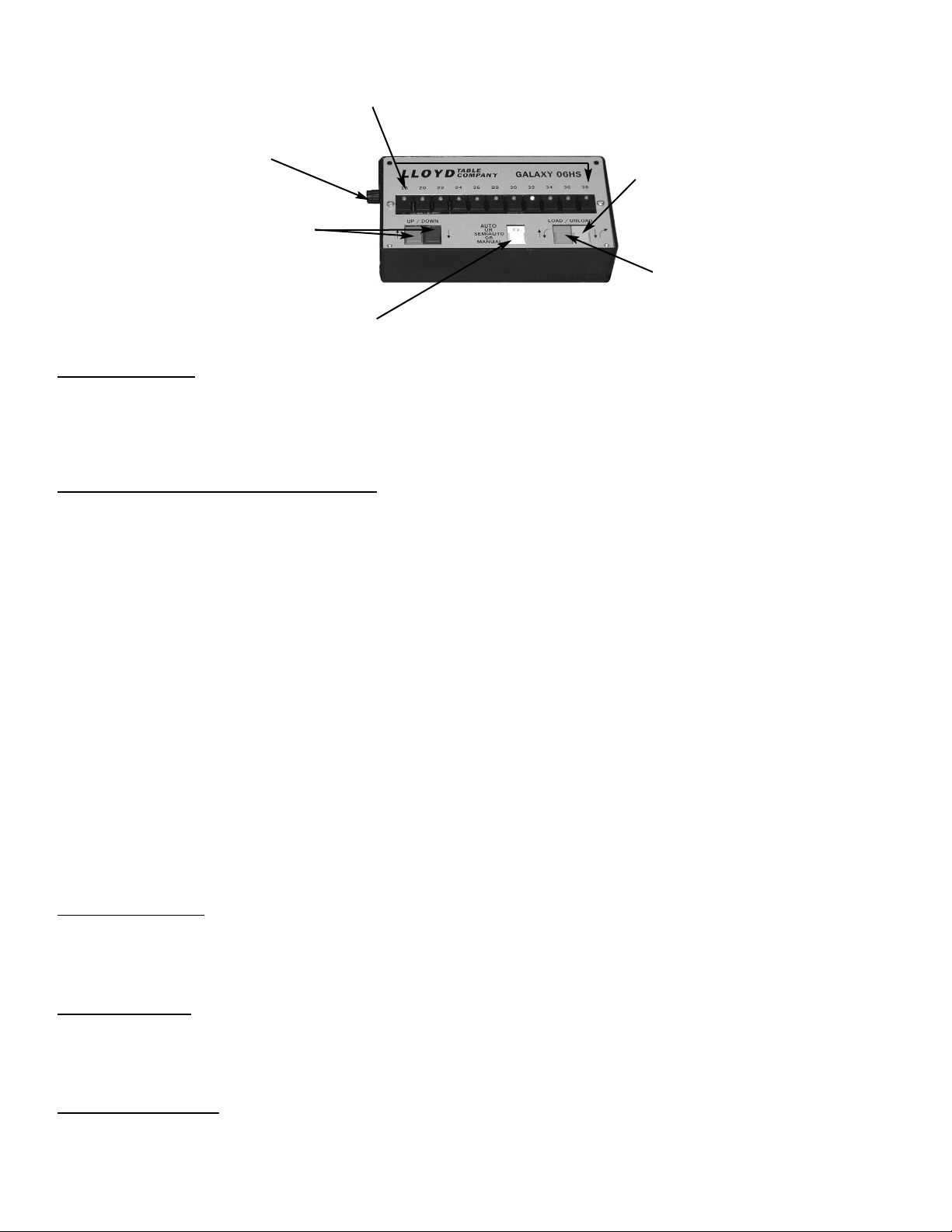

Height Select Panel

Height Select (No. 1)

The height select panel consists of eleven height select buttons whereby the operator can preselect a desired height.

The buttons range from 18 to 38 inches, at two inch increments. A button is activated when depressed, emitting a

blinking green light, and will only operate in the automatic and semi-auto mode.

Mode Switch (No.2) Auto / Semi Auto / Manual

A green light on the mode switch (#2) is the mode indicator for the table. A table has three different operation modes,

manual, semi-auto, and auto. Pressing the mode switch changes the table’s operation mode.

Manual Mode (Light-off) - The table is set in the Auto mode whenever the electrical power is first turned on.

The manual mode is indicated by the light being off on the switch.

In the manual mode; the height of the table can be adjusted with the foot pedal or with

the directional switches on the console. The table will stop when the pedal or panel

switch is released.

Semi Auto Mode ( Light- Blinks) - The semi-auto mode is indicated by a blinking green light. The foot pedal or

directional switches on the console must be held down for the table operate.

Only when the table reaches it’s preselected height,or the operator releases the

switch will the table stop.

Auto Mode (Light-on)- Pressing the mode switch (No. 2) so that the light emits a continuous green light, indicates

the table is set in the auto mode. In this mode,a console or pedal switch can be activated and

released. The table will continue to run thought it’s activated mode (load, unload, or height

selection), or can be stopped by pressing the switch again.

Unload Switch (No. 3)

The Lower (Elev.) / Tilt Switch (No. 3) lowers the table from a horizontal position and

raises it to a hylo Vertical position.

Load Switch (No. 4)

The Lower (Tilt) / Elevate Switch (No. 4) lowers the table from a Vertical position to the

horizontal position.

Up/Down Switch (No. 5)

Used for adjusting the height tables elevation hei turning the beeper sound on or off.

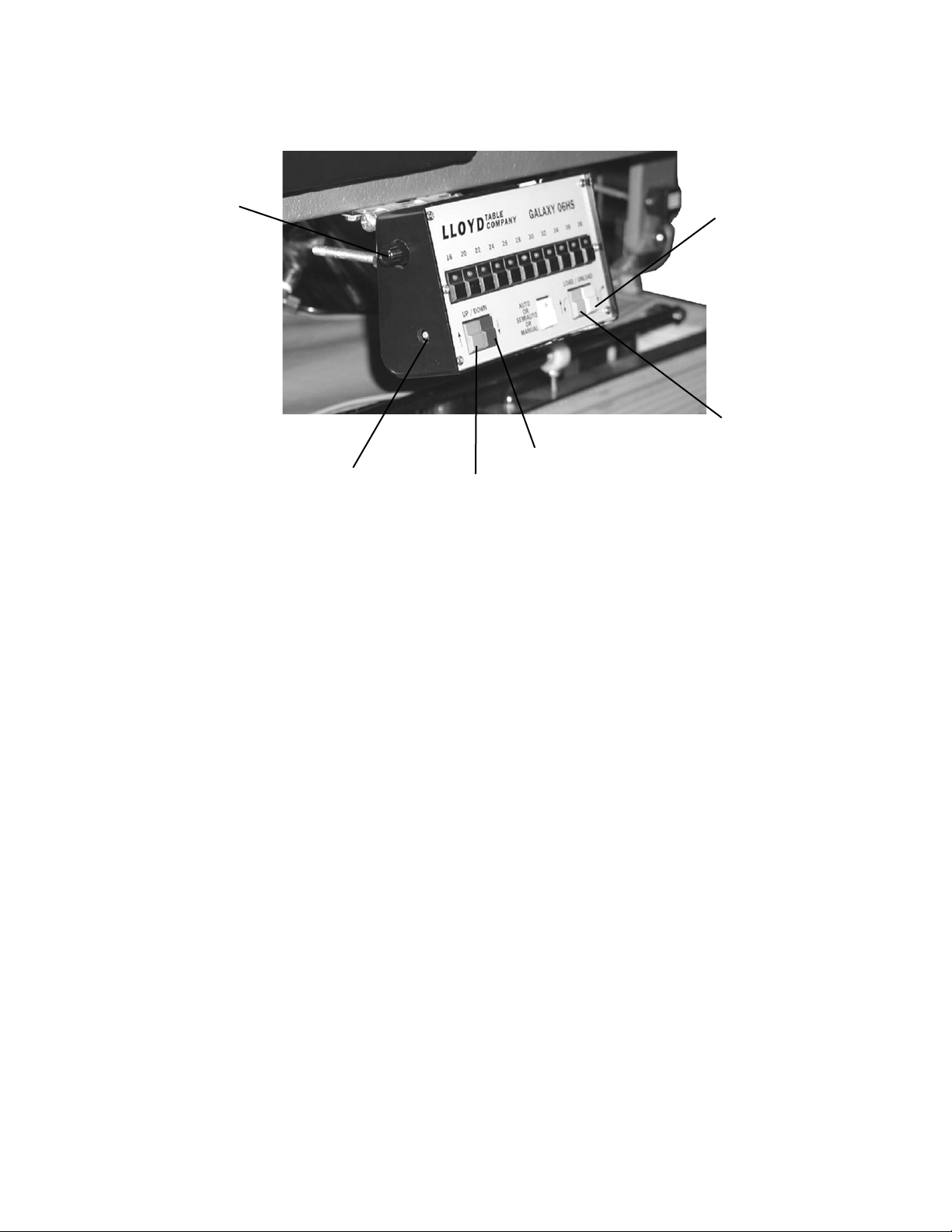

#1 Height Select

#3 Unload Switch

Horz. Down / Tilt Up Switch

#4 Load Switch

Horz. up / Tilt Down Switch

#5 Elevation Height

Up / Down

#2 Mode Switch

Auto / Semi Auto / Manual

Page 5

#6 Speed Control

Elevation / Tilt