DU40•20 Technical Manual EN 150624

© 2015 www.Lock4Safe.com Page 1 of 4

DUET

DU4020 / DU4050

Technical Description/Installation Instruction

Characteristics

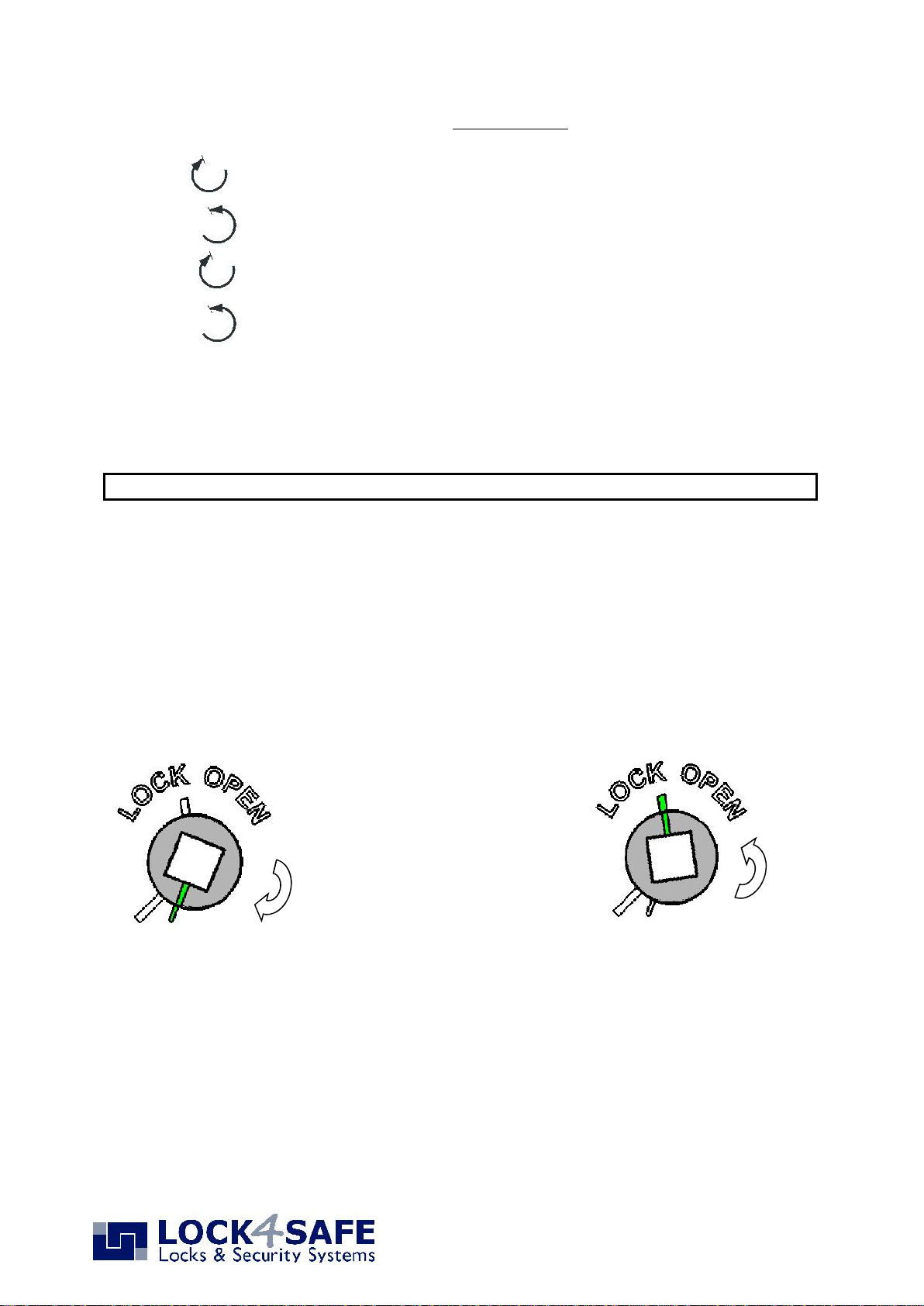

The Duet © combines an electronic safe lock and a mechanical Combination lock in one housing. The

operator uses the advantages of both Systems. The lock has the standard mounting dimensions

(66,5x41mm) and can be mounted in all 4 mounting positions. (RH, LH, VU, VD)

The lock can be mounted in typical security containers.

Dimension: 85 mm x 61 mm x 37 mm. NOTE: Because of the electronics, the housing is 5-8 mm

thicker than a normal combination lock.

Lock bolt: 25mm x 8mm with 2 holes (ready to tap M4 if required). The throw is 8mm. Max bolt force

10N.

The lock may be mounted with the “DuetInput” DIxxxx as shown in this instruction or with any

approved entry unit and separate dial. The lock is driven by a 4,7 mm (3/16 inch) square spindle, a

spline key is not required. The distance between change and opening index is 8 ¼ numbers.

The construction of the security container needs to include protection against destructive force from

outside and should not give access to security relevant parts of the lock even with open door.

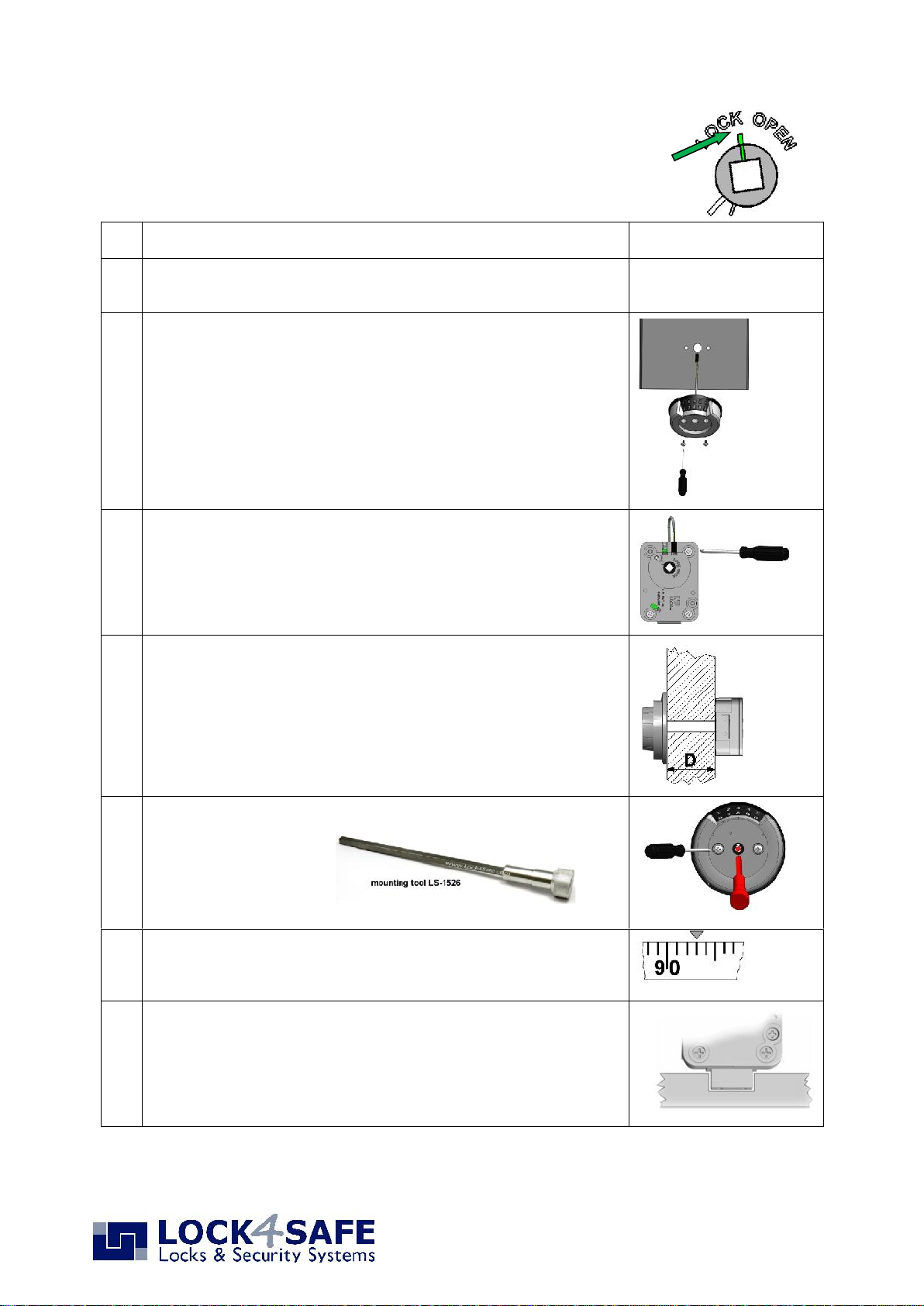

Installation dimensions

The diameter of the hole for cable and spindle should be minimal 8mm, maximal 12mm. Deburr the

spindle hole to avoid damage to the cable.

The cable does not move or wear when using the lock. However, the installer needs to take care that

the cable is not touching moving parts. For new constructions and if possible, it is advised to create a

separate hole for the cable. If spindle and cable share the same hole, use the plastic tube over the

spindle only to separate it from the cable.