2

Table of Contents

1Please Observe the Following...................................................................................................3

1.1 Emphasized Sections...........................................................................................................3

1.2 For Your Safety.....................................................................................................................3

1.3 Unpacking and Inspection ..................................................................................................4

1.4 Packing List...........................................................................................................................4

1.5 Features.................................................................................................................................4

1.6 Field of Application (Intended Use)...................................................................................5

2Description...................................................................................................................................6

2.1 Theory of Operation..................................................................................................................6

2.2 Display, operating elements and connections......................................................................7

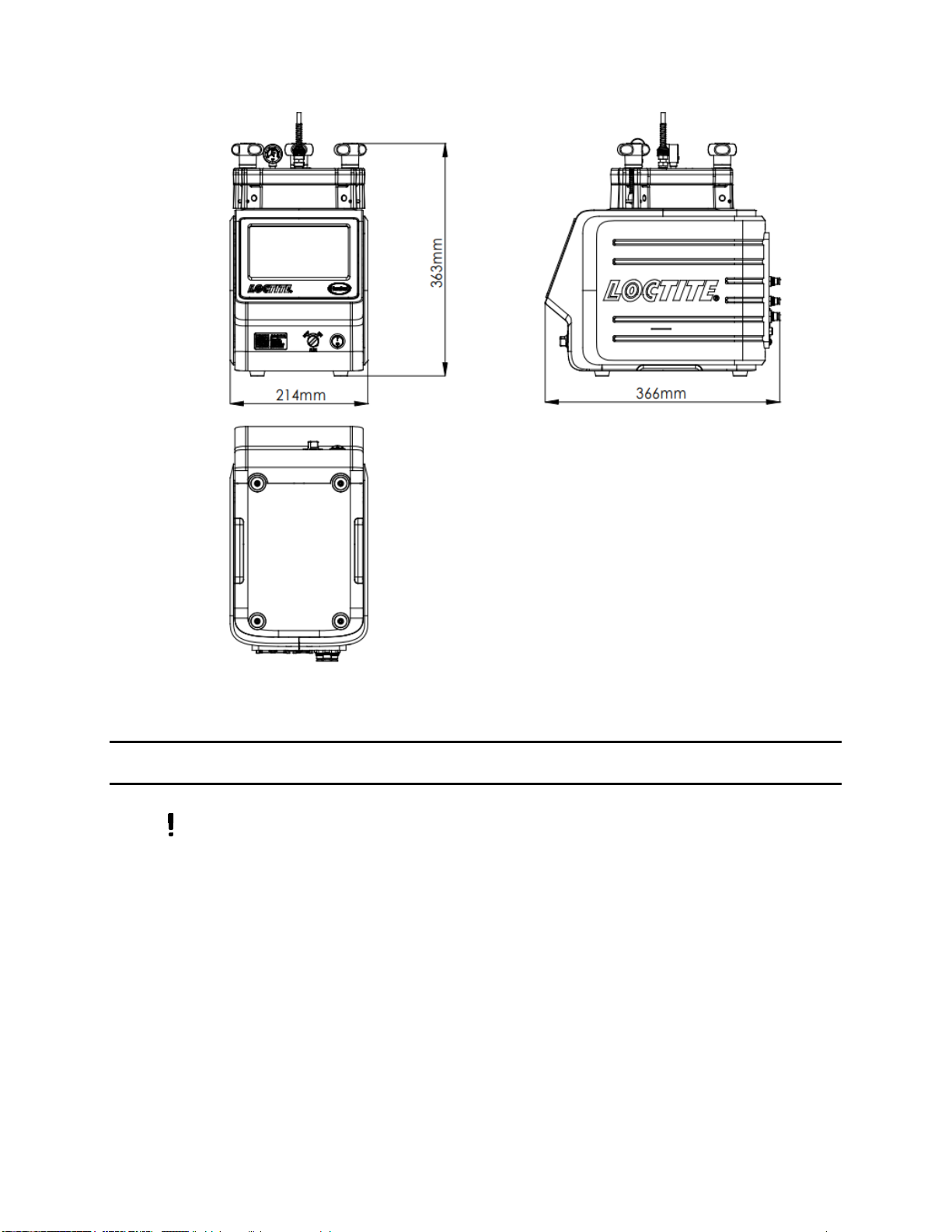

3Technical Data.............................................................................................................................8

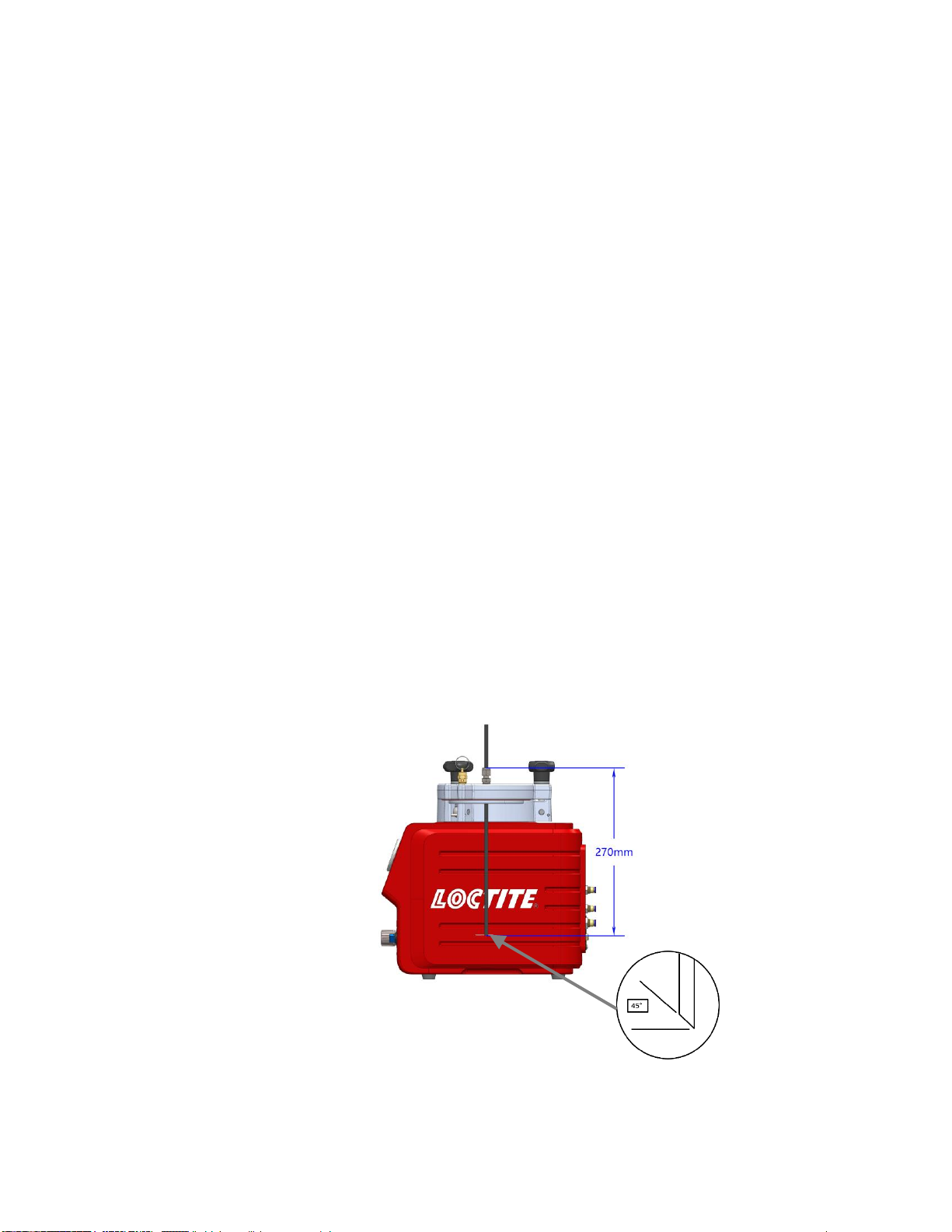

4Installation....................................................................................................................................9

4.1 Environmental and Operating Conditions..............................................................................9

4.2 Connecting the Unit................................................................................................................10

4.3 Filling and Refilling the Product Reservoir..........................................................................11

5Operation....................................................................................................................................12

5.1 Turn on the Unit......................................................................................................................12

5.2 Main Page ................................................................................................................................12

5.3 Parameter Setting Page.........................................................................................................12

5.4 Communication Setting Page................................................................................................15

5.5 Equipment Info Page .............................................................................................................20

5.6 Set-up Configurations ...........................................................................................................21

5.7 Adjusting the Level Sensor....................................................................................................23

5.8 More Setting ...........................................................................................................................24

6Application Hints.......................................................................................................................27

7Troubleshooting.........................................................................................................................28