5

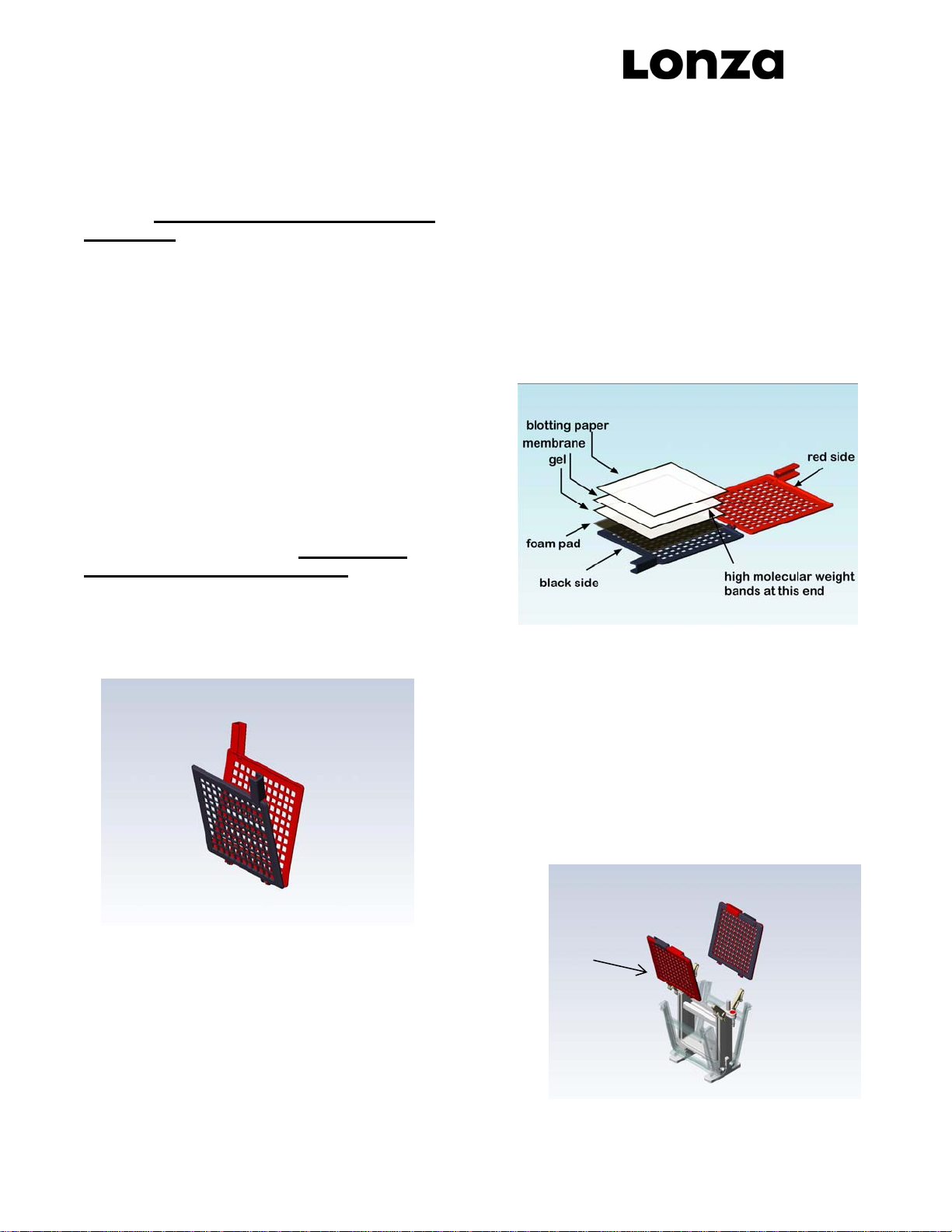

6. Close doors and re-latch by pressing down on the

white latches. If running one blot, slide blank

adapter plate into the side without the blotting

cassette.

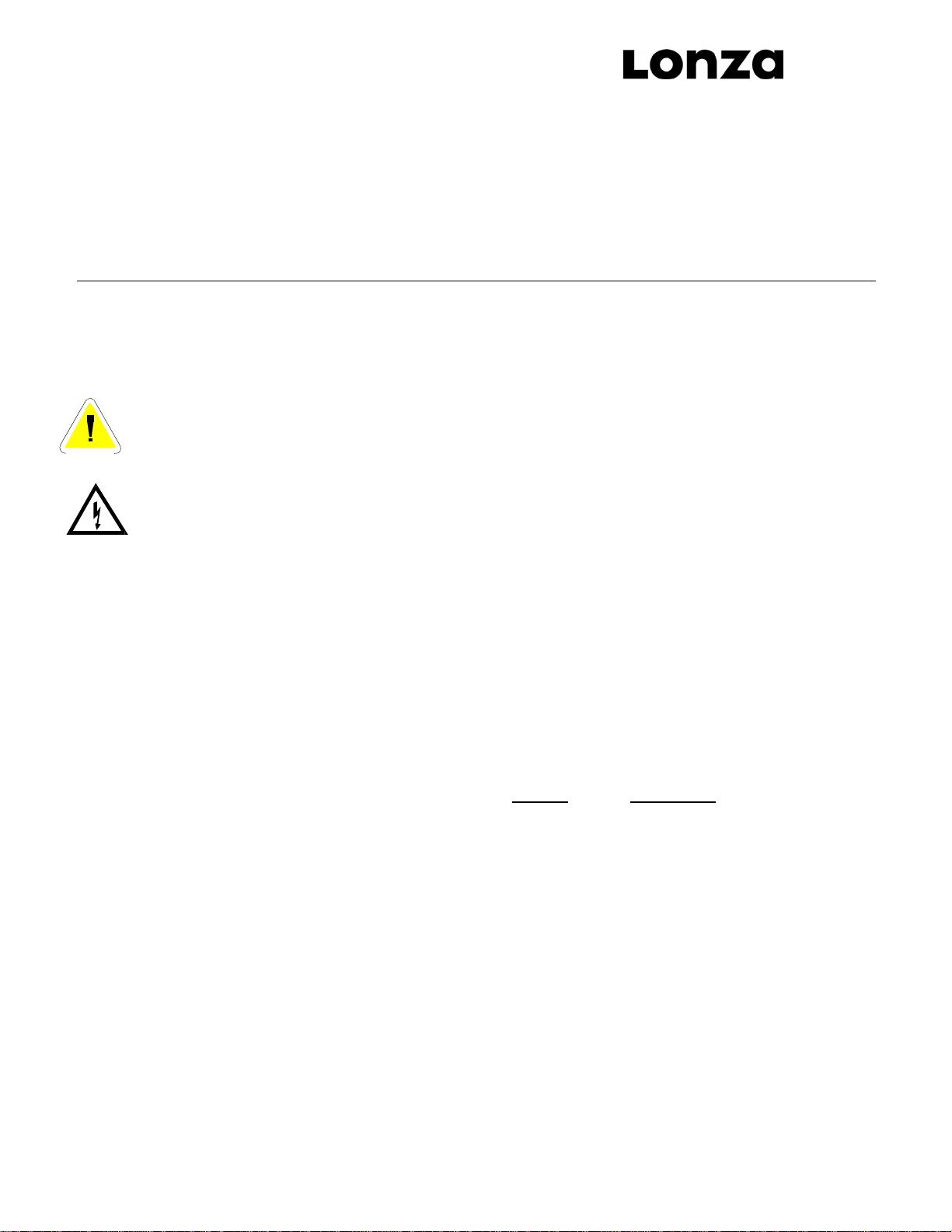

4.2 Electro-Blotting Procedure

1. Place stirring bar in bottom of reservoir in stirring

corral. Place core/blotting cassette assembly into

lower reservoir. The anode (red) and cathode (black)

electrodes are color-coded on both the core/cassette

assembly and lower reservoir. Ensure the red dot on

the cassette assembly is on the same side as the

red receptacle on the lower reservoir.

2. Pour 1 liter of freshly prepared, chilled (4º) Towbin

buffer into lower buffer reservoir. Buffer will percolate

into central core.

3. Attach safety cover, as shown in figure 11.

4. Connect the leads to the power supply, matching the

color-coded red to red and black to black. See

Section 5.2 for recommended power conditions.

Begin transfer by electrophoresis.

4.3 Removing the Blot

1. Turn the power supply off and disconnect the leads

from the power supply. Remove the safety cover

from the unit, by simultaneously pressing down on

the white push pins with your thumbs, while lifting up

on the yellow safety cover with your fingers. See

Figure 2. Do not remove safety cover by pulling

up on leads!

2. Blotting cassettes can be removed by leaving the

core in place and opening the top latches of the

core, opening the doors and lifting the cassettes out.

Unlatch the blotting cassettes and remove blot from

blotting sandwich.

SECTION 5

Running Conditions

5.1 Recommended Power for Slab Gels:

Precise electrophoresis conditions will vary according to

the number and type of gels used, buffer conditions

employed, power input, and the general goal of the

experiment. Refer to section 5.4 for in depth discussions

on practical and theoretical approaches to protein gel

electrophoresis.

Using standard SDS-PAGE buffer systems (see section

5.3). For two 1.0mm thick gels at room temperature use

the following conditions at constant voltage:

200 VDC for ~60 minutes, or if faster runs are

desired, 250 VDC for 30 minutes.

As the thickness of gel increases, the mA’s increase

proportionally.

At constant voltage 200-250 VDC, the proteins will

migrate at a constant rate during electrophoresis with

adequate heating appropriate for denaturing gels.

Increasing the voltage/mA (for each single gel thickness

and percentage) will speed mobility but increase the risk

of overheating.

5.2 Recommended Power for Electro-Blotting:

Using standard SDS-PAGE electro-blotting buffer

systems (see section 5.3) use the following conditions:

100 VDC @ 90 minutes.

5.3 Recommended Buffers

For Best Results use AccuGENE®Electrophoresis

Buffers (see ordering info).

5.4 References

1. Hames, B.D. (ed.) (1998). Gel Electrophoresis of

Proteins. A Practical Approach. 3rd edn. Oxford

University Press, Oxford. Ch. 1,3.

2. Sambrook, J., Fritsch, Russell, D. (2001). Molecular

Cloning. A Laboratory Manual. 3rd edn. Cold Spring

Harbor Laboratory Press, Cold Spring Harbor, New

York. A8.40-A8.55

3. Ausubel, F.M., Brent, R., Kingston, R.E., Moore,

D.D., Seidman, J.G., Smith, J.A., Struhl, K. (ed)

(1993). Current Protocols in Molecular Biology. Vol.

Protein Denaturing

Buffer: Protein Electro-Blotting Buffer:

Figure 11

TG-SDS (1X): TG-SDS Towbin (1X) 20% MeOH:

0.025M Tris base 0.025M Tris base

0.192M Glycine 0.192M Glycine

0.1% (w/v) SDS 0.05-0.1% (w/v) SDS

pH 8.3 20% (v/v) Methanol