6

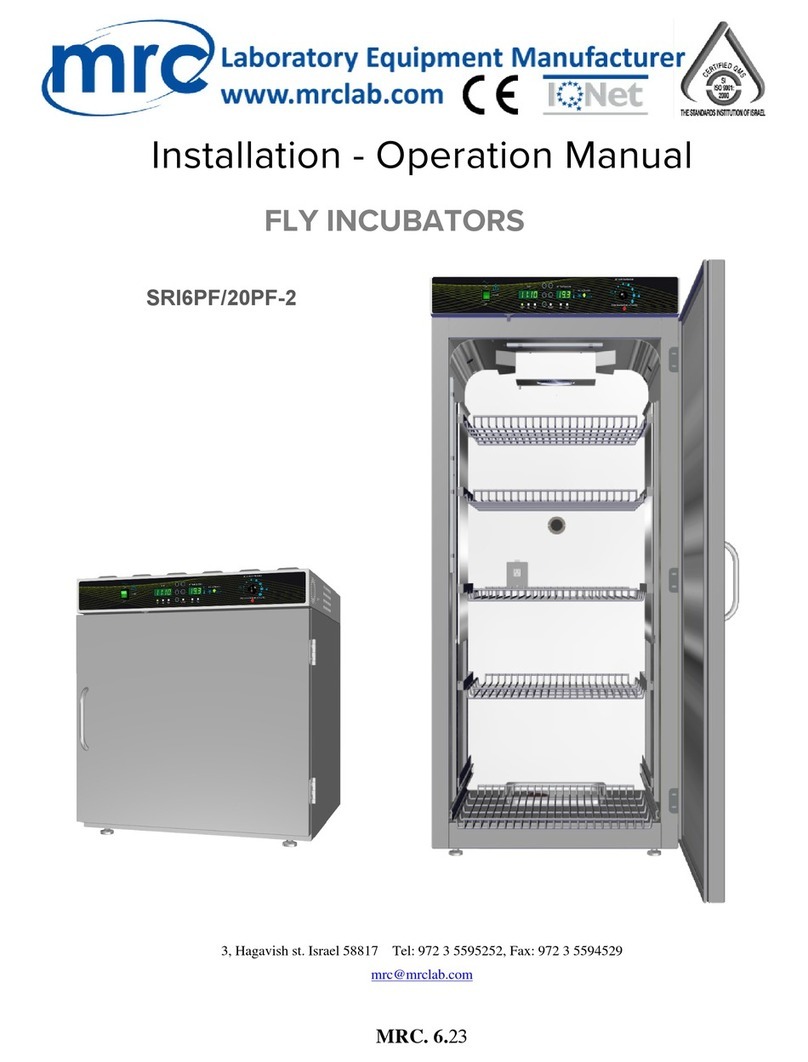

Technical Specification for Tri-Gas Incubator

Quick Guide to Operation of Tri-gas Incubator

Restore settings:

Temperature control value 37.0℃

Humidity alarm value 90%(not controlled)

CO2control value 0.0%

CO2supply circuit A circuit

The metal surface in the interior of the equipment (inner chamber, motor

impeller, fan cover, shelf, support and so on) shall be sprayed with H2O2before

use, and cleaned with soft cotton cloth so as to get rid of dirt and sundries.

As a required step to operate the incubator normally, this operation can’t be

omitted. Otherwise, it will directly affect incubation effect, or even lead to

failure. (Please refer to 8.1.6 Shortcut Menu—90℃high-temperature and

high-humidity disinfection for the specific operation method).

After disinfection, calibration and verification shall be conducted before

incubation in accordance with following steps.

1. Please turn off the power switch and cut off the power.

2. Open the external door and the glass doors, inject about 3L of distilled water

into the bottom of the inner tank of the incubator, and then close the doors.

3. Connect the gas source. Select one or two circuit of CO2supply according to

the actual operation requirements, adjust the output pressure of reducing

valve in the range of 0.08 to 0.1MPa, and check whether there is any gas

leakage. Please refer to the Installation and Operation Instruction of CO2

Reducing Valves for the specific operation method.

4. Connect the power supply. Connect AC power via power wire, turn on the

power switch in the lower right side of the control box at the back of the

incubator to start up the equipment after the connected power

supply meets the stipulated requirements.

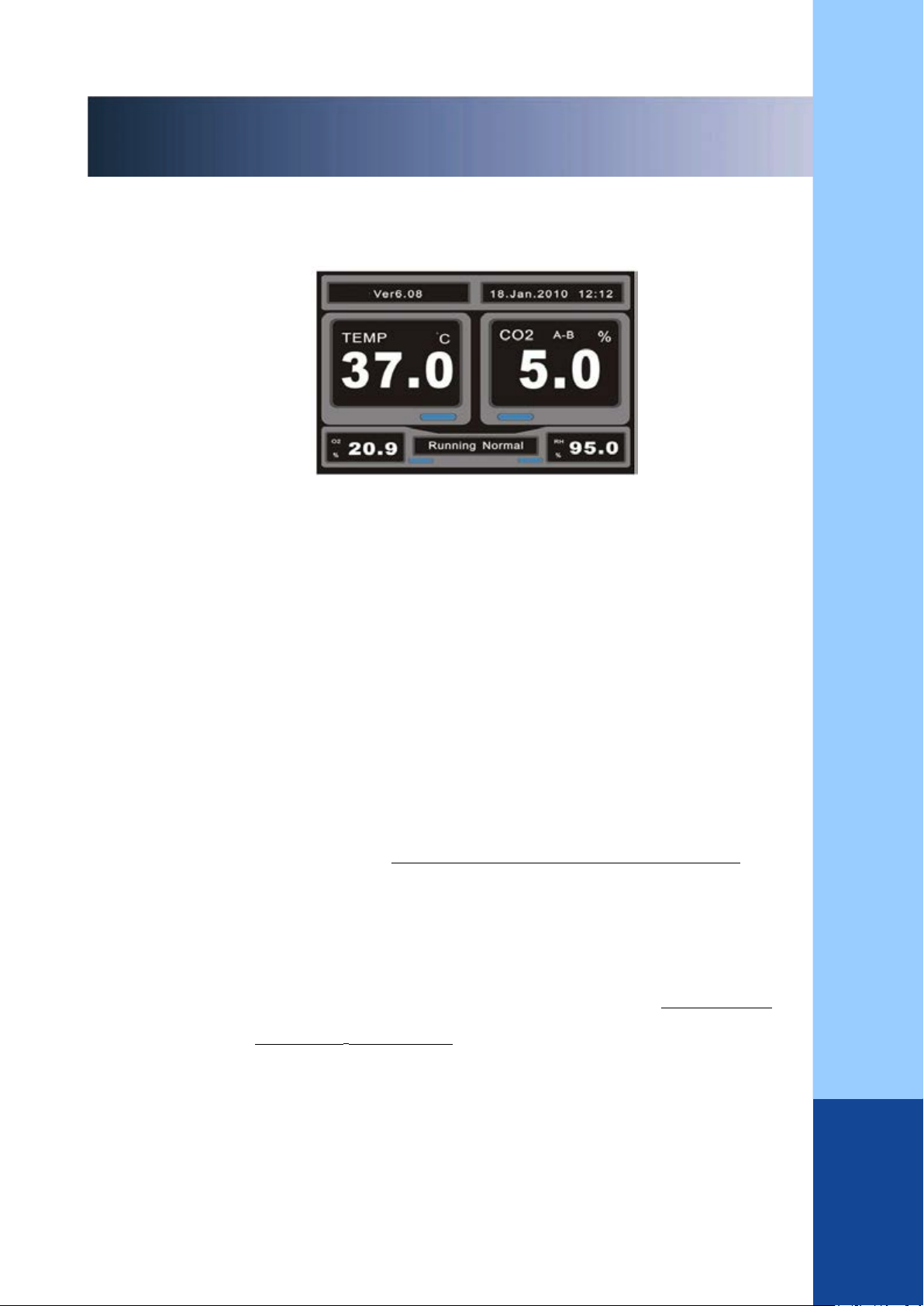

5.After the Logo of “MRC”is displayed in LCD, the system will start

self-testing for about 30 seconds, and the inspection process and result will

be synchronized in LCD.