2

TABLE OF CONTENTS

INTRODUCTION..................................................................................................................................................1

SERIAL NUMBER LOCATION ............................................................................................................................4

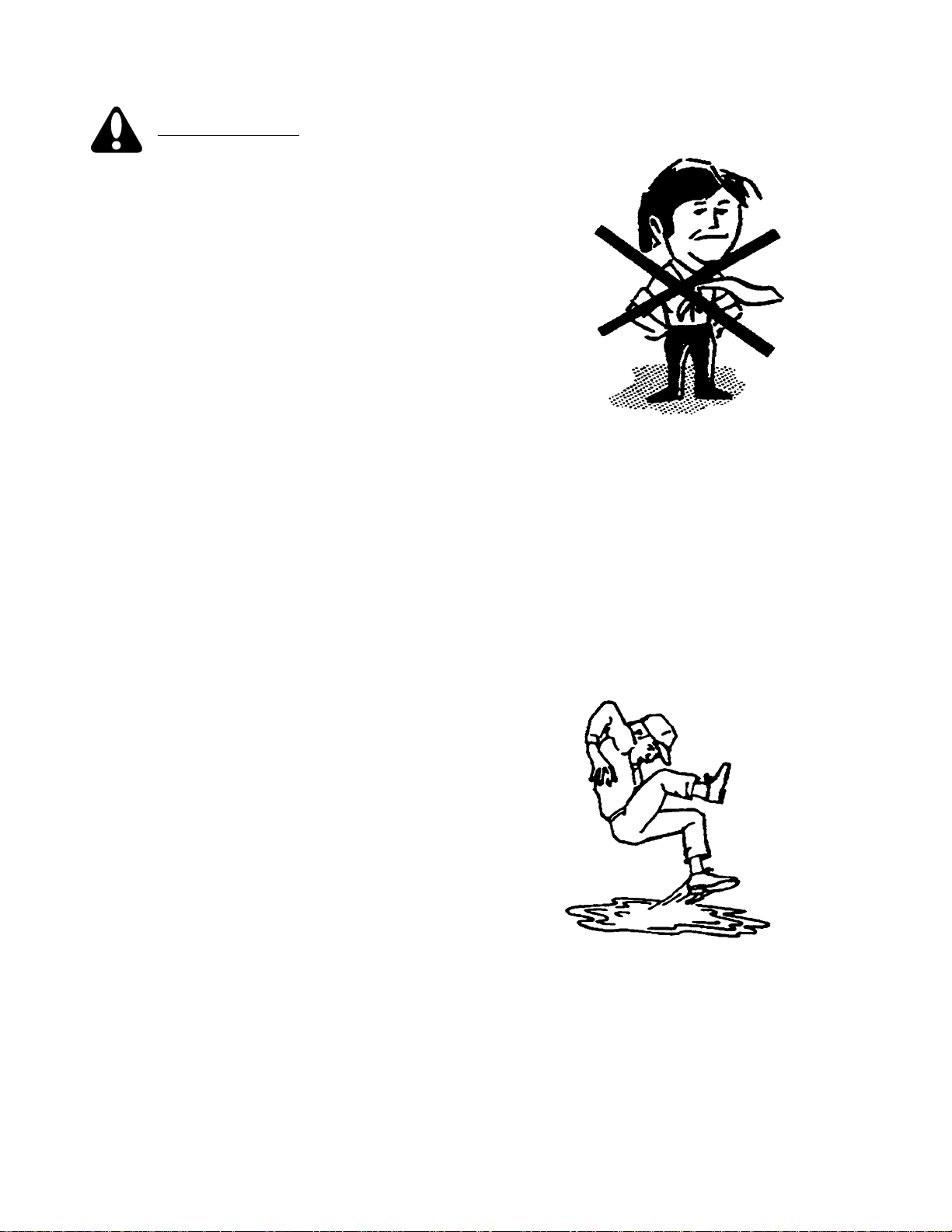

SAFETY ...............................................................................................................................................................5

SAFETY ALERT SYMBOL........................................................................................................................5

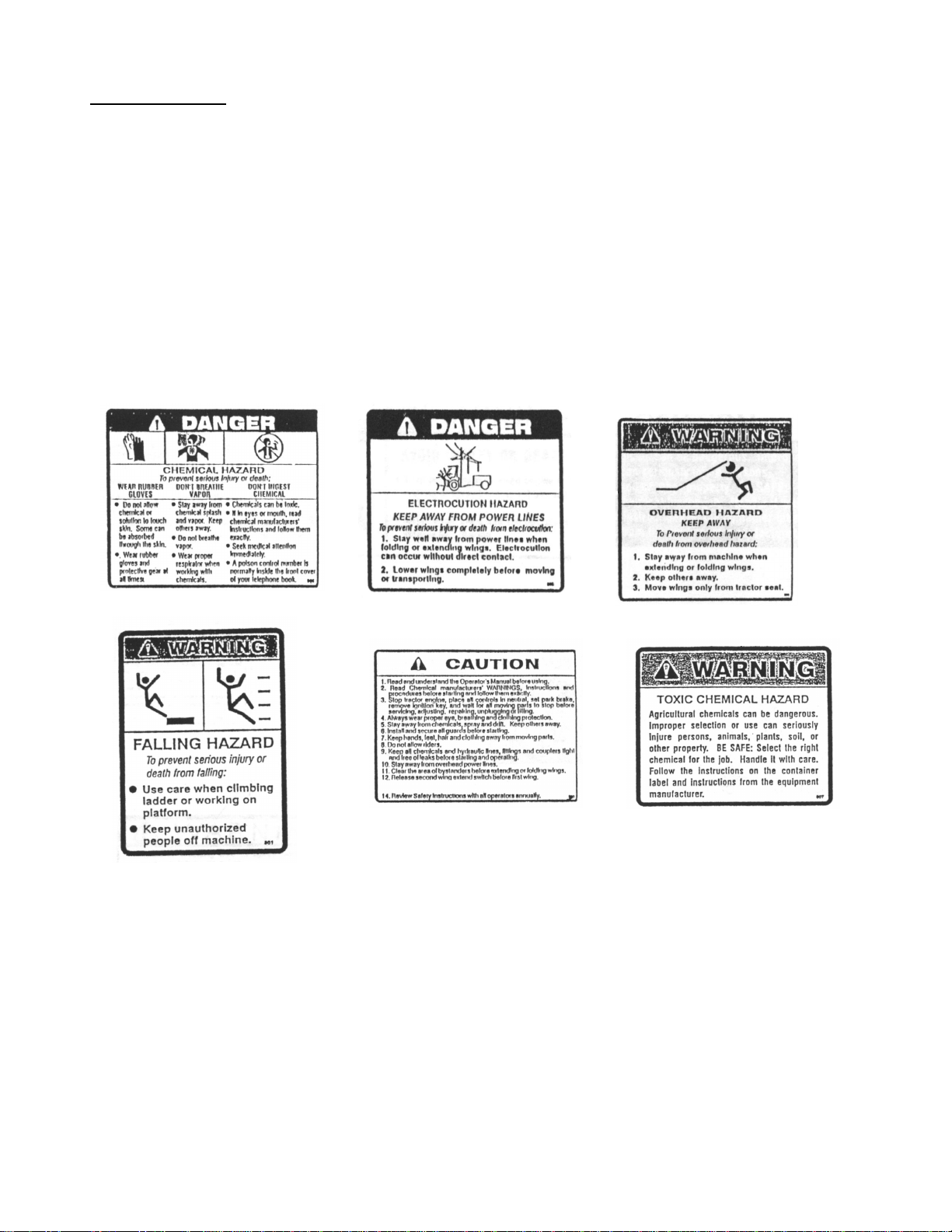

SIGNAL WORDS.......................................................................................................................................5

SAFETY SIGNS.........................................................................................................................................6

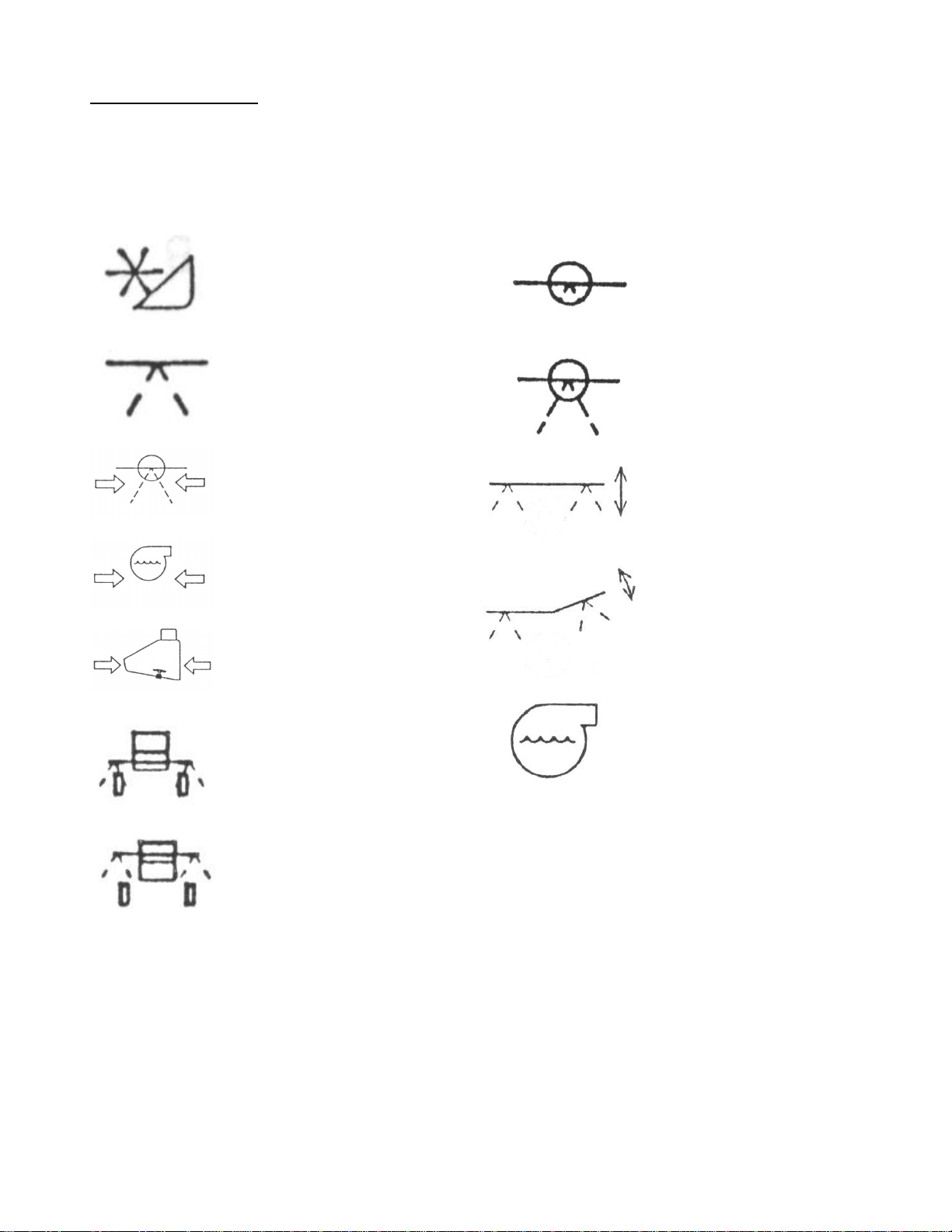

Symbol Definitions.....................................................................................................................................7

CHEMICAL SAFETY..........................................................................................................................................10

Pesticide Hazards and Toxicity Levels....................................................................................................12

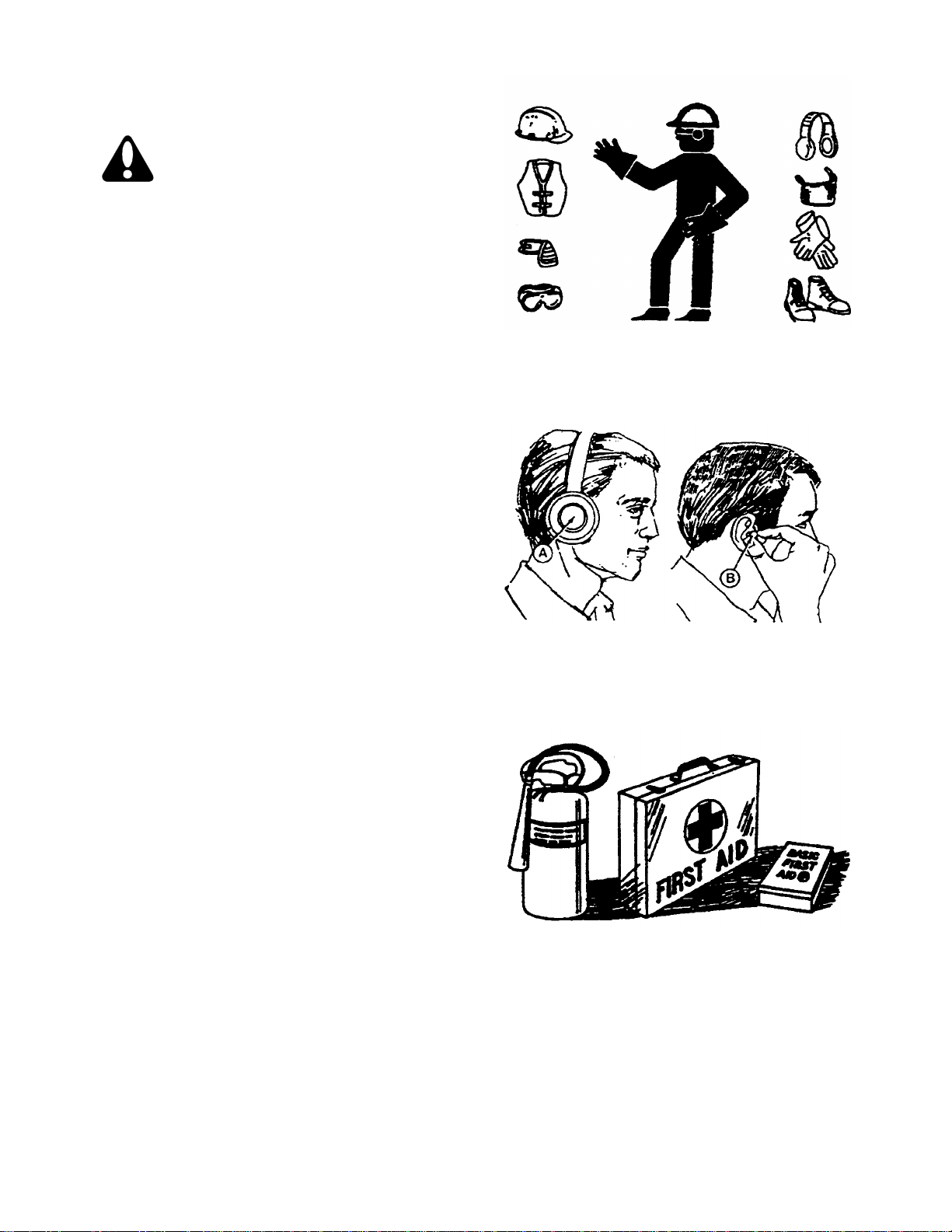

Protective Clothing...................................................................................................................................12

Cleaning Contaminated Clothing.............................................................................................................13

Clean Water Personal Wash and Emergency Rinse Tank......................................................................14

Emergency First Aid for Pesticide Poisoning...........................................................................................15

SPECIFICATIONS .............................................................................................................................................16

TORQUE SPECIFICATIONS.............................................................................................................................17

OPERATION......................................................................................................................................................19

Your Responsibilities as an Owner/Operator ..........................................................................................19

To the New Operator ...............................................................................................................................19

Driving the Sprayer..................................................................................................................................20

Pre-Starting Checks: Annual ..................................................................................................................21

Pre-Starting Checks: Daily......................................................................................................................22

Break-in Period........................................................................................................................................24

Boom Controls.........................................................................................................................................25

Rear Center Boom..............................................................................................................................26

Attaching the Sprayer to the Windrower.............................................................................................27

Boom Props........................................................................................................................................28

Spray System ..........................................................................................................................................29

Operating the Sprayer Pump..............................................................................................................29

Starting the Sprayer Pump.................................................................................................................30

Checking for Pump Operation............................................................................................................30

Bottom Filling the Tank.......................................................................................................................31

Top Filling the Tank............................................................................................................................32

Triple Rinsing Chemical Containers...................................................................................................32

Flushing the Spray System and Tank Cleaning.................................................................................33

Daily Cleaning...............................................................................................................................33

Cleaning the Tank when Changing Chemicals or Storing the Sprayer Attachment.....................34

Agitation..............................................................................................................................................35

Sprayer Calibration.............................................................................................................................36

Sprayer Calibration (metric) ...............................................................................................................39

Crop Dividers......................................................................................................................................42

Rate Controller ...................................................................................................................................43

The MT-3405 Automatic Rate Controller ......................................................................................43

Boom Spray Selection...................................................................................................................43

Boom Control Valves.....................................................................................................................44

Calibration Values For The MT-3405 Rate Controller........................................................................44

Boom Width Calibration Values ....................................................................................................44

Flow Meter Calibration Number ....................................................................................................44

DICKEY-john Radar Velocity Sensor............................................................................................45

Transporting the Sprayer.........................................................................................................................46

Detaching the Sprayer.............................................................................................................................49

Storage Procedure...................................................................................................................................52

Winterizing the Spray System ............................................................................................................52