TABLE OF CONTENTS

4.2 Operational Safety......................................................................................................................... 64

4.2.1 Shutting Down the Machine .................................................................................................... 64

4.3 Attaching Hay Conditioner to Header..............................................................................................65

4.4 Detaching Hay Conditioner from Header ......................................................................................... 66

4.4.1 Detaching Hay Conditioner: Windrower Method....................................................................... 66

4.4.2 Detaching Hay Conditioner: Lifting Method.............................................................................. 70

4.5 Detaching Feed Deck and Rock Grate............................................................................................ 74

4.6 Break-in Period.............................................................................................................................. 77

4.7 Preseason Check .......................................................................................................................... 78

4.8 Daily Startup Check....................................................................................................................... 79

4.9 Conditioner Operation.................................................................................................................... 80

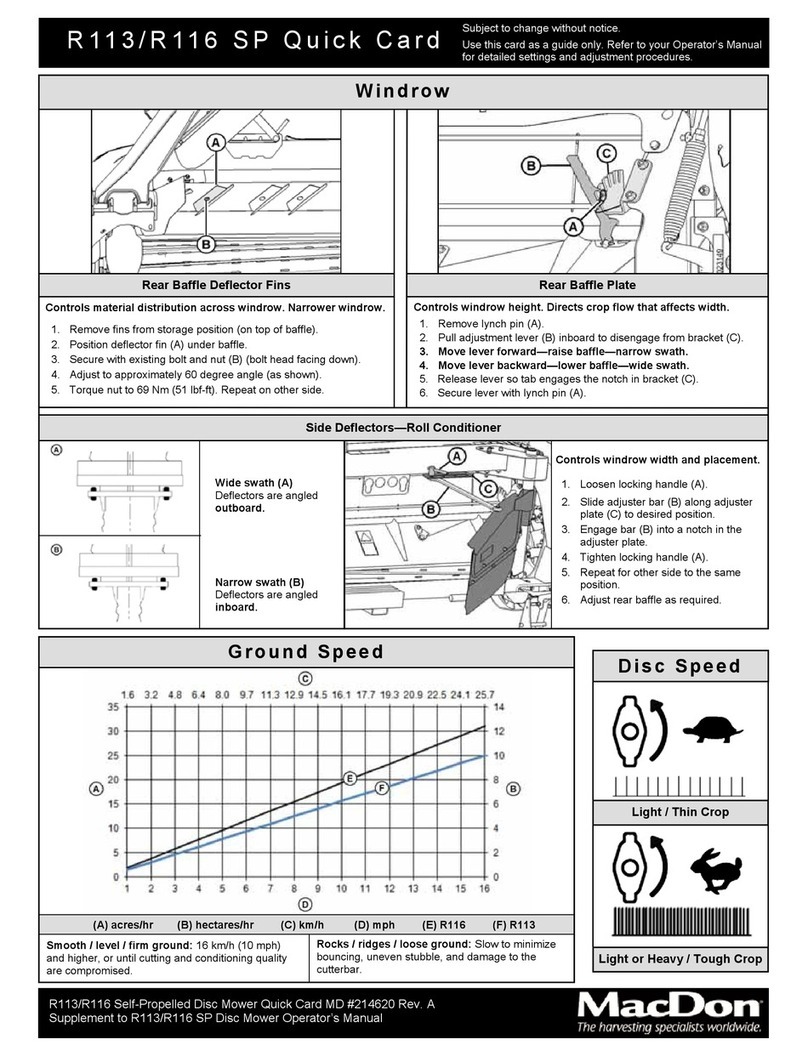

4.9.1 Roll and Feed Draper Speed................................................................................................... 80

4.9.2 Adjusting Roll Gap ................................................................................................................. 80

4.9.3 Checking and Adjusting Roll Timing......................................................................................... 81

4.9.4 Adjusting Conditioner Roll Tension ......................................................................................... 83

4.9.5 Forming Shields..................................................................................................................... 83

Adjusting Forming Shield Height...................................................................................... 84

Adjusting Side Deflectors ................................................................................................ 84

Adjusting Rear Deflector (Fluffer Shield)........................................................................... 85

Adjusting Deflector Fins .................................................................................................. 85

4.9.6 Unplugging the Conditioner..................................................................................................... 85

4.10 Storage......................................................................................................................................... 86

5 Maintenance........................................................................................................................................ 87

5.1 Preparation for Servicing................................................................................................................ 87

5.2 Recommended Safety Procedures..................................................................................................88

5.3 Drive Shields................................................................................................................................. 89

5.4 Lubrication .................................................................................................................................... 90

5.4.1 Lubricants.............................................................................................................................. 90

5.4.2 Greasing Procedure ............................................................................................................... 90

5.4.3 Lubrication Points................................................................................................................... 91

5.5 Hydraulics..................................................................................................................................... 94

5.5.1 Hydraulic Hoses and Lines .....................................................................................................94

5.6 Feed Draper.................................................................................................................................. 95

5.6.1 Adjusting Feed Draper Tension ............................................................................................... 95

5.7 Drive Belt...................................................................................................................................... 96

5.7.1 Adjusting Drive Belt Tension.................................................................................................... 96

5.7.2 Adjusting Drive Belt Pulley Alignment ...................................................................................... 97

5.7.3 Checking and Adjusting Drive Belt Tracking............................................................................. 98

5.7.4 Removing Drive Belt .............................................................................................................100

5.7.5 Installing Drive Belt ...............................................................................................................100

5.8 Maintenance Schedule..................................................................................................................102

5.9 Troubleshooting............................................................................................................................104

6Repa

ir Parts .......................................................................................................................................107

6.1 Abbreviations ...............................................................................................................................107

6.1.1 Serial Number Breaks ...........................................................................................................107

6.2 Lower Roll and Frame Assembly ...................................................................................................108

6.3 Upper Roll Assembly ....................................................................................................................110

6.4 Cover and Supports......................................................................................................................112

6.5 Hydraulic Motor, Mounts, and Tensioner.........................................................................................116

6.6Belt Drive and Shield ....................................................................................................................120

6.7Hydraulic Completion Package......................................................................................................122

6.8Gears and Roll Coupling Assembly................................................................................................126

6.9Forming Shields ...........................................................................................................................128

169254 ivRev. D