TABLE OF CONTENTS

3.12 Adjusting the Transport Lights ........................................................................................................ 82

4 Operating the Header .......................................................................................................................... 83

4.1 Header Float ................................................................................................................................. 83

4.1.1 Checking Float....................................................................................................................... 83

4.1.2 Adjusting Float for M200 and M205 Self-Propelled Windrowers................................................. 84

4.1.3 Removing and Restoring Float for M1240 Self-Propelled Windrowers........................................ 84

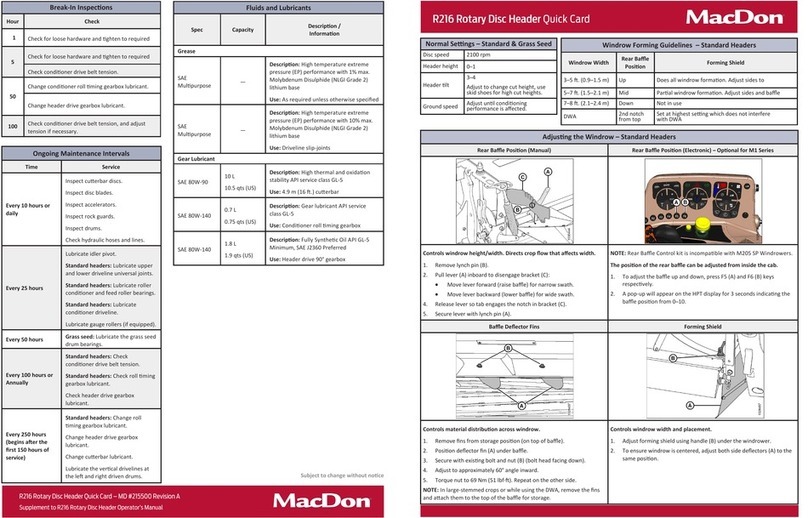

4.2 Roll Gap........................................................................................................................................ 86

4.2.1 Checking Roll Gap ................................................................................................................. 86

4.2.2 Adjusting Roll Gap ................................................................................................................. 87

4.3 Roll Tension .................................................................................................................................. 89

4.3.1 Adjusting Roll Tension ............................................................................................................ 89

4.4 Roll Timing .................................................................................................................................... 90

4.4.1 Checking Roll Timing.............................................................................................................. 90

4.4.2 Adjusting Roll Timing.............................................................................................................. 91

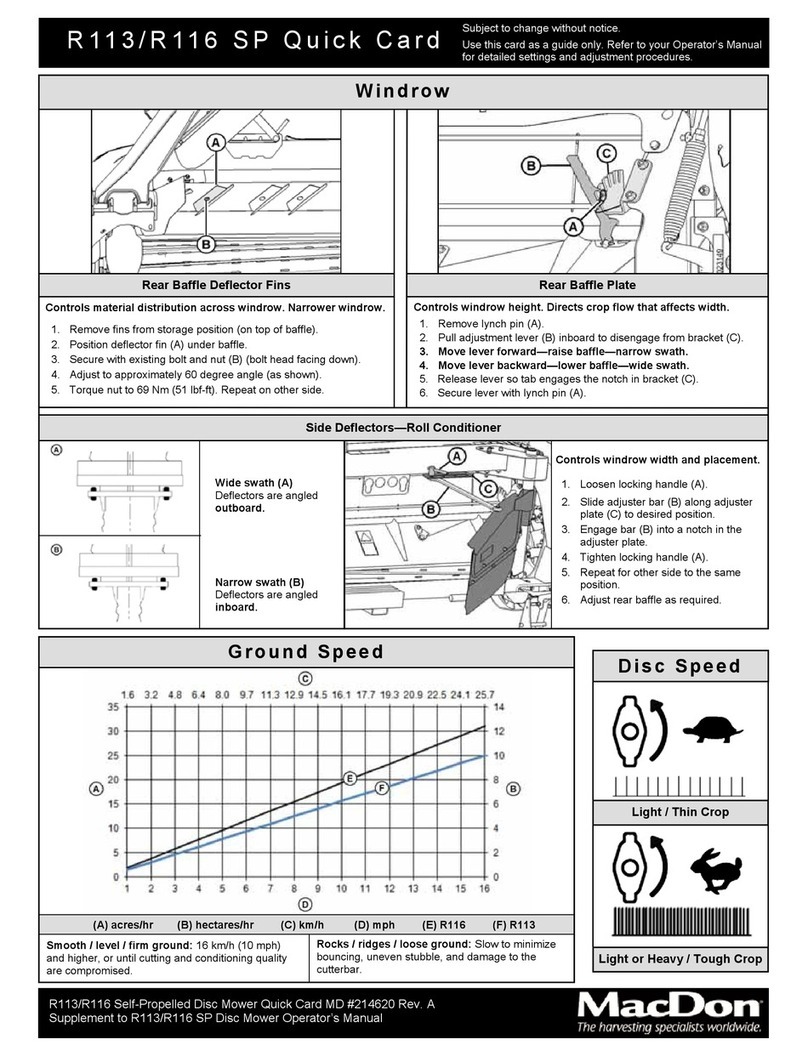

4.5 Forming Shields ............................................................................................................................ 92

4.5.1 Adjusting the Side Deflectors .................................................................................................. 92

4.5.2 Adjusting the Rear Deflector (Fluffer Shield)............................................................................. 94

4.5.3 Adjusting the Swath Baffle ...................................................................................................... 94

4.6 Header Angle ................................................................................................................................ 96

4.7 Cutting Height ............................................................................................................................... 97

4.7.1 Adjusting Gauge Roller Height ................................................................................................ 97

4.7.2 Adjusting the Skid Shoe Height ............................................................................................... 97

4.8 Disc Speed.................................................................................................................................... 99

4.9 Ground Speed..............................................................................................................................100

4.10 Double Windrowing.......................................................................................................................101

4.11 Tall Crop Feed Plates....................................................................................................................102

4.11.1 Removing the Tall Crop Feed Plates from Storage...................................................................102

Installing Tall Crop Feed Plates under Driven Deflector ....................................................103

Installing Tall Crop Feed Plates under Driveline Deflector .................................................103

4.11.2 Removing Tall Crop Feed Plates ............................................................................................104

Removing Tall Crop Feed Plates from under Driven Deflector ...........................................105

Removing Tall Crop Feed Plates from under Driveline Deflector........................................105

4.11.3 Returning Tall Crop Feed Plates to Storage.............................................................................106

4.12 Tall Crop Divider Option ................................................................................................................107

4.12.1 Installing Tall Crop Divider......................................................................................................107

4.12.2 Removing Tall Crop Divider....................................................................................................108

4.13 Overshot Auger ............................................................................................................................110

4.13.1 Adjusting the Overshot Auger.................................................................................................110

4.14 Stripper Bars ................................................................................................................................113

4.14.1 Adjusting the Stripper Bar ......................................................................................................113

4.15 Haying .........................................................................................................................................116

4.15.1 Curing ..................................................................................................................................116

4.15.2 Topsoil Moisture ....................................................................................................................116

4.15.3 Weather and Topography.......................................................................................................116

4.15.4 Windrow Characteristics ........................................................................................................116

4.15.5 Driving on Windrow ...............................................................................................................117

4.15.6 Raking and Tedding...............................................................................................................117

4.15.7 Using Chemical Drying Agents...............................................................................................117

4.16 Unplugging the Header .................................................................................................................118

5Main

tenance and Servicing ................................................................................................................119

5.1 Preparation for Servicing...............................................................................................................119

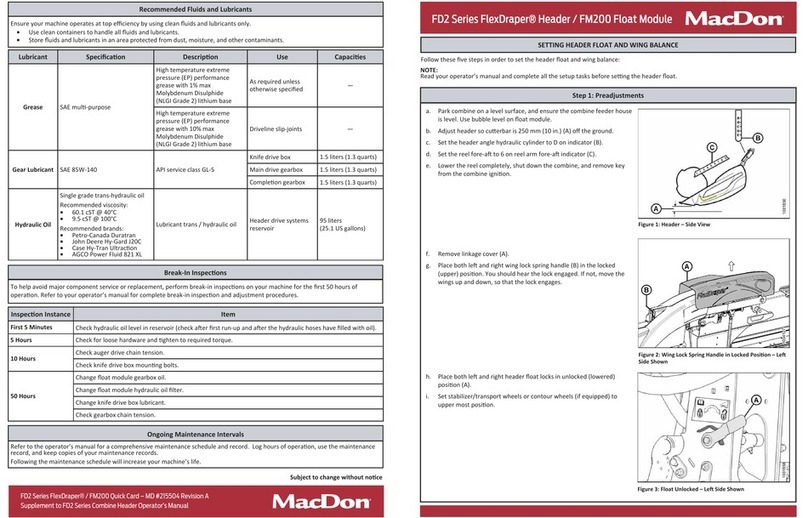

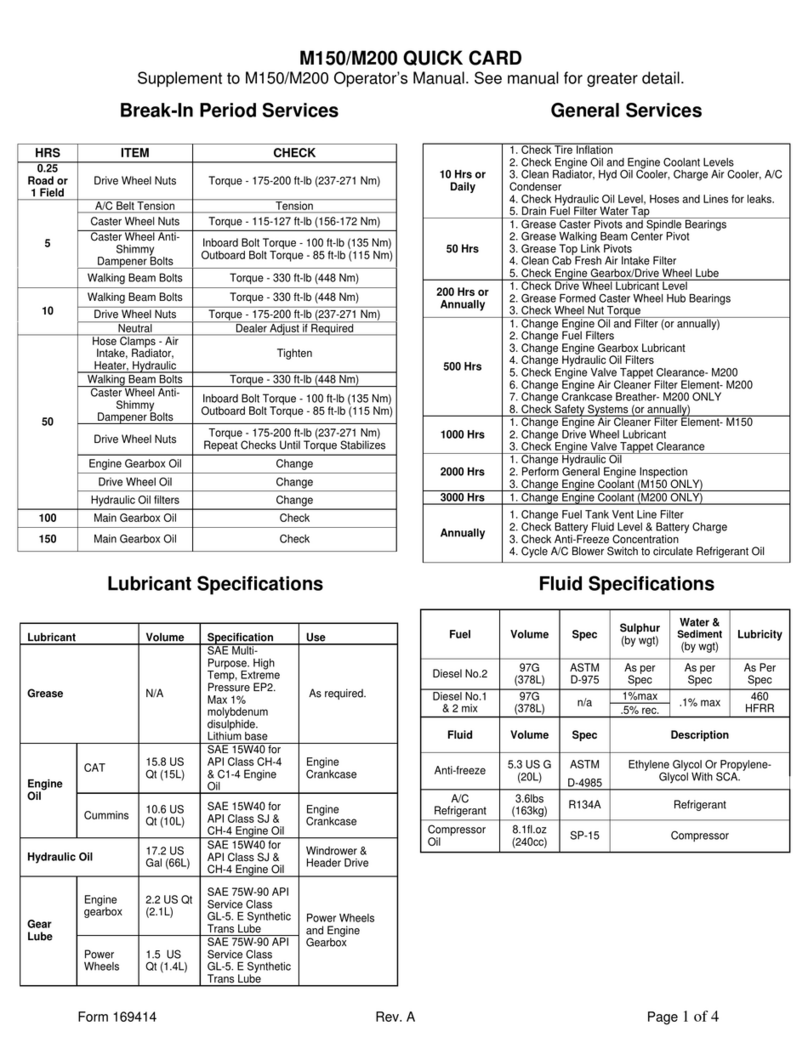

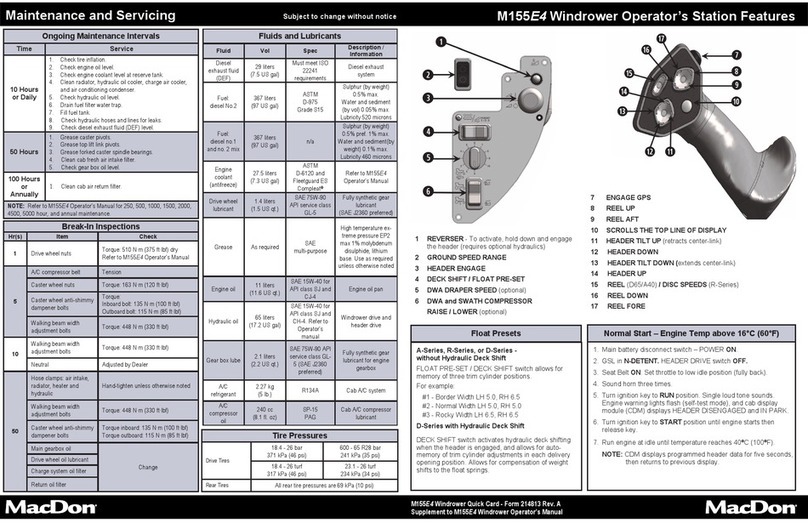

5.2 Recommended Fluids and Lubricants ............................................................................................120

5.3 Maintenance Requirements...........................................................................................................121

214014 viii Revision B