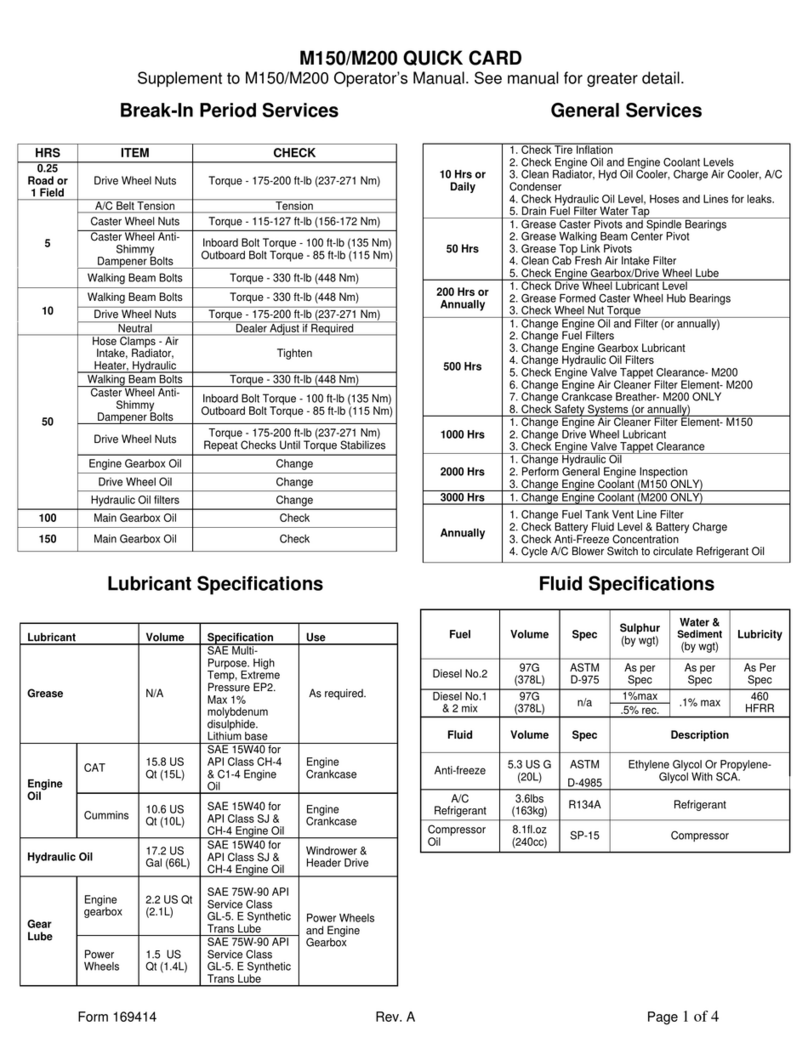

Break-In Service

Please Refer to Maintenance and Servicing Section of Operators Manual

Draper Clinic Handout

2

Find your operators manual at: www.macdon.com/support/operators-manuals

At 5 hours

Check knife drive belt tension (single or untimed knife)

2. Loosen the two bolts (A) that secure the motor assembly to the header end sheet (see

figure 7.103 at right).

3. Turn adjuster bolt (B) clockwise to move the drive motor until a force of 20 ft·lbf (80 N·m)

deflects the belt ¾ inches (18 mm) at mid-span.

To prolong belt life do not overtighten. Please refer to the maintenance and servicing section of your operators manual

Check knife drive belt tension (timed double knifed)

1. Open end sheet.

2. Loosen the two bolts (A) on drive belt idler bracket (see figure 7.117 at right).

3. Position pry bar under idler bracket, and push bracket upwards until a force of 6 ft·lbf (27

N·m) deflects the timing belt ½ inch (13mm) at mid-span.

4. Tighten nuts (A) on idler mounting bracket.

5. Loosen bolts (B) and adjust guide (A) shown in figure 7.118 on right. The measurement

should be 0.02-0.04 inches (0.5 –1.0 mm).

6. Readjust tension of a new belt after a short run-in period (about 5 hours).

Check for Loose Hardware

Check for loose hardware and tighten to required torque. Refer to torque specifications section of operators manual.

Check knife drive box mounting bolts

Check the four knife drive box mounting bolts (A1, A2) torque after the first 10 hours

operation and every 100 hours thereafter. Tighten knife drive box side bolts (A1) first,

then the bottom bolts (A2). Torque to 200-ft lbs (271 N m).

At 10 hours

Check Reservoir Hydraulic Fluid on Combine Adapter

Check fluid level every 25 hours with cutterbar just touching the ground. Check when oil is

cold and with center link fully retracted. At ambient temperatures above 95ºF (35ºC) it may

be necessary to lower oil level slightly to prevent overflow. CA20 and CA25 combine

adapters use 15w –40 engine oil in this reservoir. For other models please refer to your

operators manual to find the correct fluid requirements for your specific equipment.

Maintain oil level as indicated by (D) in figure 7.32

At 5 minutes