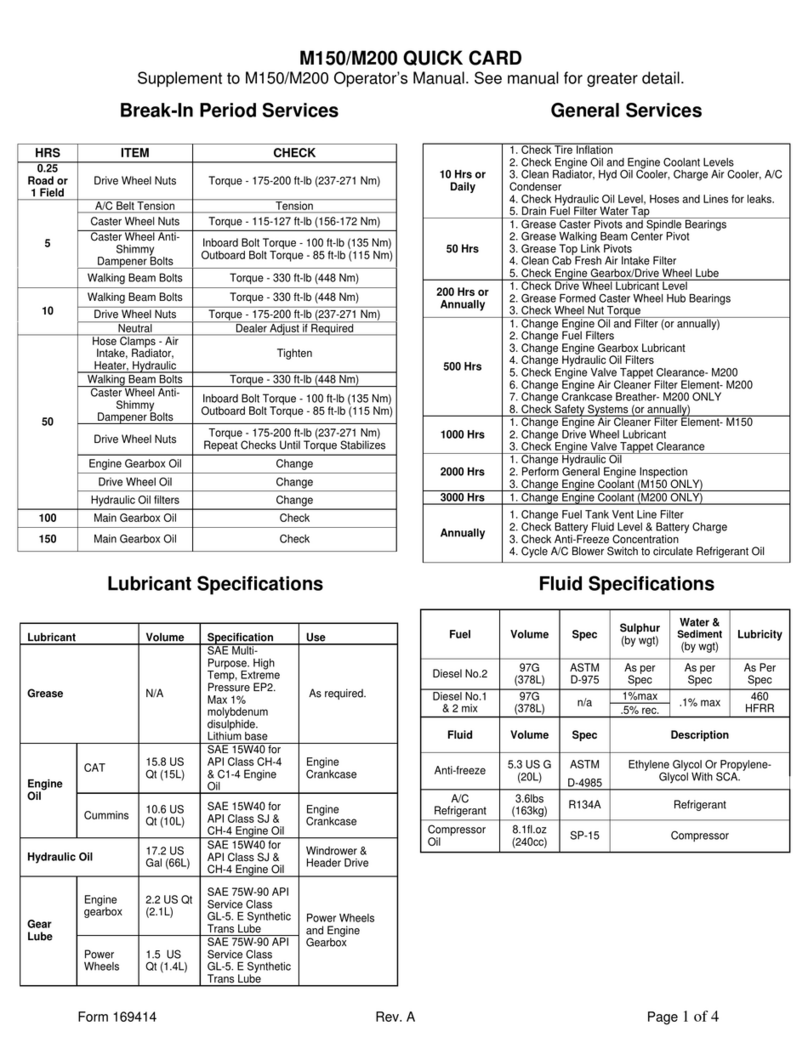

Form # 169018 Model Year - 2009

1

INTRODUCTION

This instruction describes the unloading, set-up and pre-delivery requirements for the MacDon M Series Self-

Propelled M150 and M200 Windrower Tractors. Use the table of contents to guide you to specific areas.

Retain this instruction for future reference.

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE,

OR USE THE MACHINE.

TABLE OF CONTENTS

INTRODUCTION........................................................................................................................................................1

GENERAL SAFETY...................................................................................................................................................2

RECOMMENDED TORQUES ...................................................................................................................................4

A. GENERAL..................................................................................................................................................4

B. SAE BOLTS...............................................................................................................................................4

C. METRIC BOLTS ........................................................................................................................................4

D. HYDRAULIC FITTINGS.............................................................................................................................5

ACCRONYMS AND ABBREVIATIONS .....................................................................................................................6

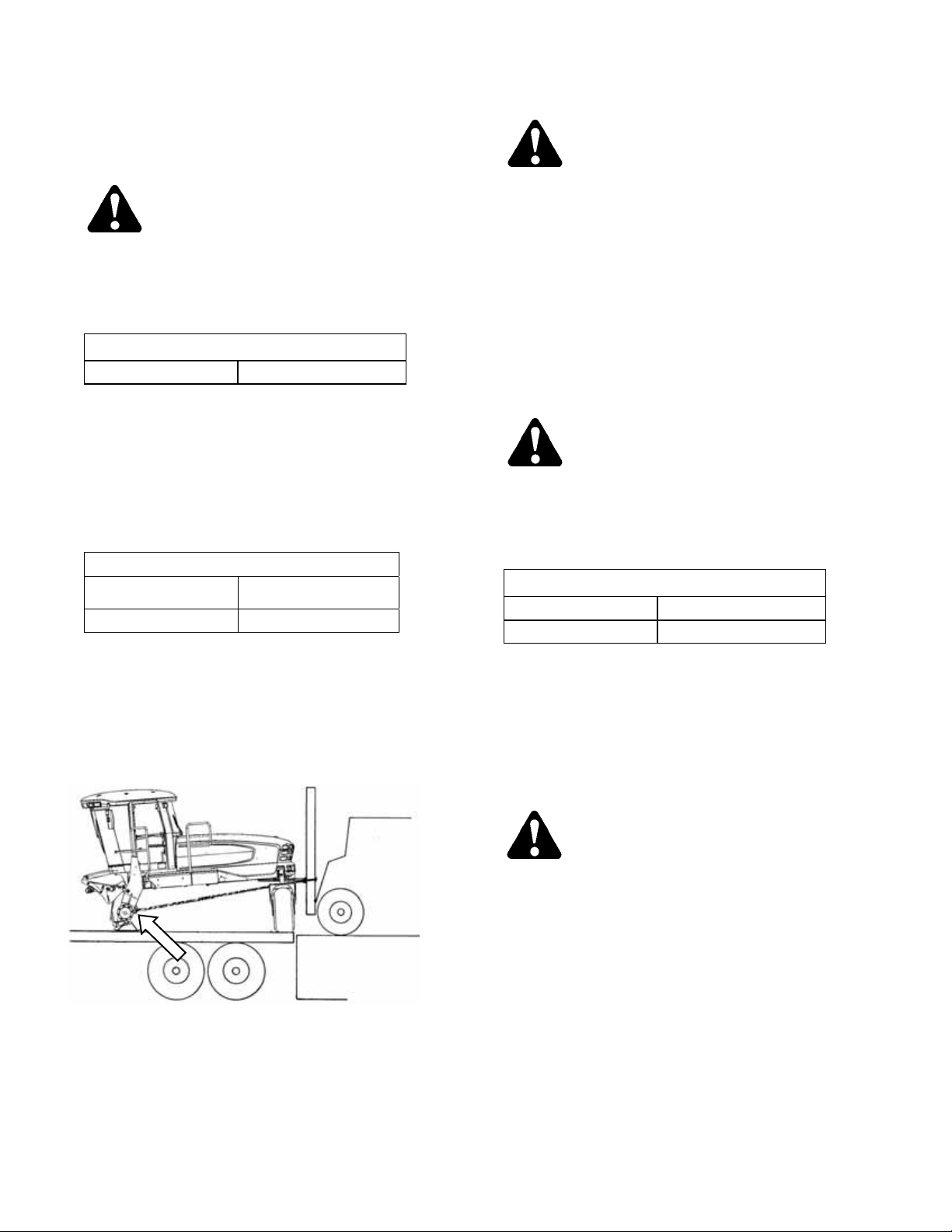

STEP 1. UNLOAD TRACTOR...........................................................................................................................7

A. TWO FORKLIFT METHOD .......................................................................................................................7

B. SINGLE FORKLIFT METHOD ..................................................................................................................8

METHOD 1........................................................................................................................................................................ 8

METHOD 2........................................................................................................................................................................ 8

STEP 2. REPOSITION RH LEG......................................................................................................................10

STEP 3. INSTALL FRONT WHEELS ..............................................................................................................11

STEP 4. REPOSITION CASTER WHEELS ....................................................................................................11

STEP 5. INSTALL STEPS ...............................................................................................................................12

STEP 6. INSTALL CENTER LINK...................................................................................................................13

STEP 7. INSTALL BATTERIES (2) .................................................................................................................13

STEP 8. INSTALL AM/FM RADIO...................................................................................................................14

STEP 9. ATTACH HEADER............................................................................................................................16

I. HEADER ATTACHMENT - D SERIES.............................................................................................................. 16

II. HEADER ATTACHMENT – A SERIES ............................................................................................................. 20

III. HEADER ATTACHMENT – R SERIES ............................................................................................................. 23

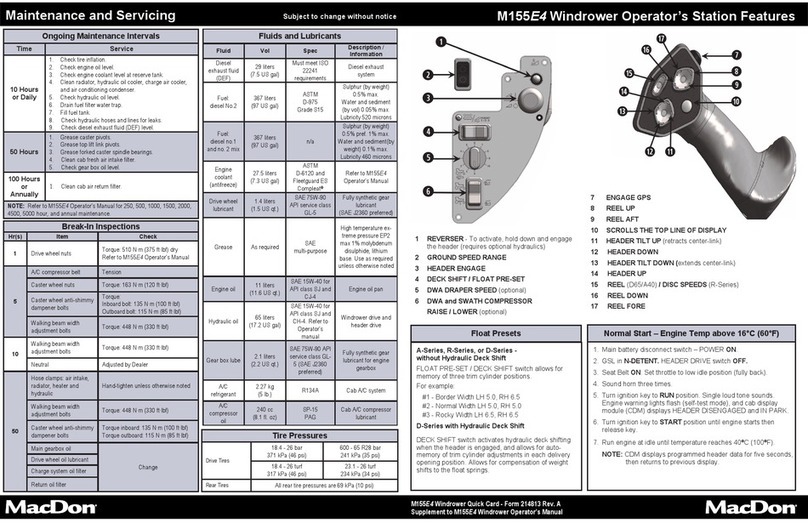

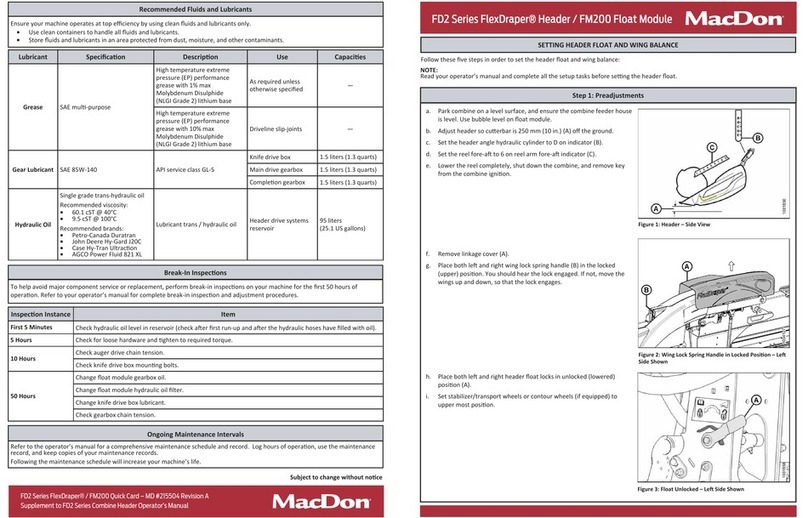

STEP 10. LUBRICATE MACHINE.....................................................................................................................27

STEP 11. PROGRAM CDM...............................................................................................................................29

STEP 12. PERFORM PRE-DELIVERY CHECKS.............................................................................................35

A. FINAL DRIVE LUBRICANT LEVEL.........................................................................................................35

B. TIRE PRESSURES .................................................................................................................................35

C. ENGINE COOLANT.................................................................................................................................35

D. AIR CLEANER.........................................................................................................................................35

E. HYDRAULIC OIL LEVEL.........................................................................................................................36

F. FUEL SEPARATOR ................................................................................................................................36

G. GEAR BOX LUBRICANT LEVEL ............................................................................................................37

H. A/C COMPRESSOR BELT......................................................................................................................37

I. PERFORM SAFETY SYSTEM CHECKS................................................................................................37

J. OPERATIONAL CHECKS .......................................................................................................................39

I. ENGINE WARNING LIGHTS ............................................................................................................................ 39

II. START ENGINE................................................................................................................................................ 39

III. GAUGES AND CDM DISPLAY......................................................................................................................... 40

IV. ENGINE SPEED ............................................................................................................................................... 40

V. OPERATOR’S PRESENCE SYSTEM CHECKS...............................................................................................41

VI. EXTERIOR LIGHTS.......................................................................................................................................... 42

VII. INTERIOR LIGHTS........................................................................................................................................... 43

VIII. A/C AND HEATER............................................................................................................................................ 43

K. MANUALS ...............................................................................................................................................43

L. CAB INTERIOR .......................................................................................................................................43