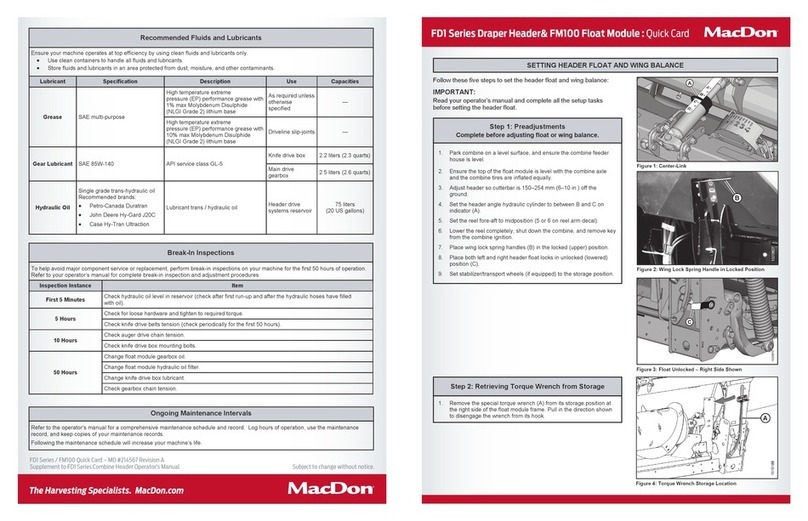

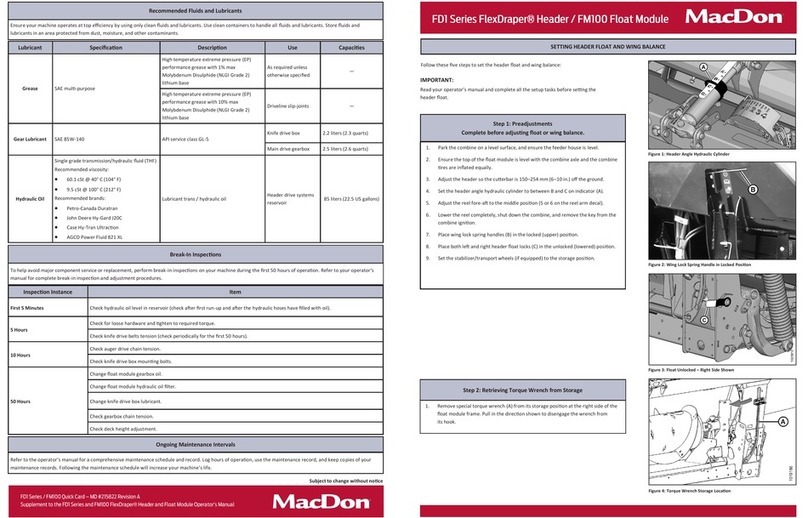

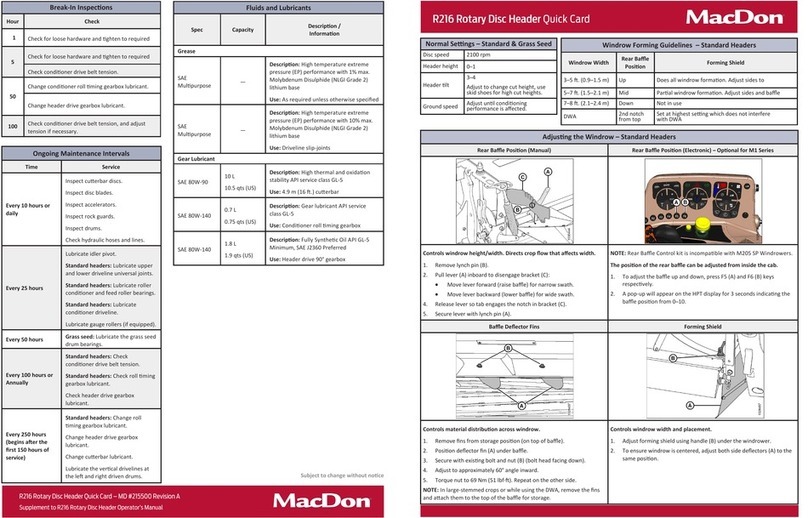

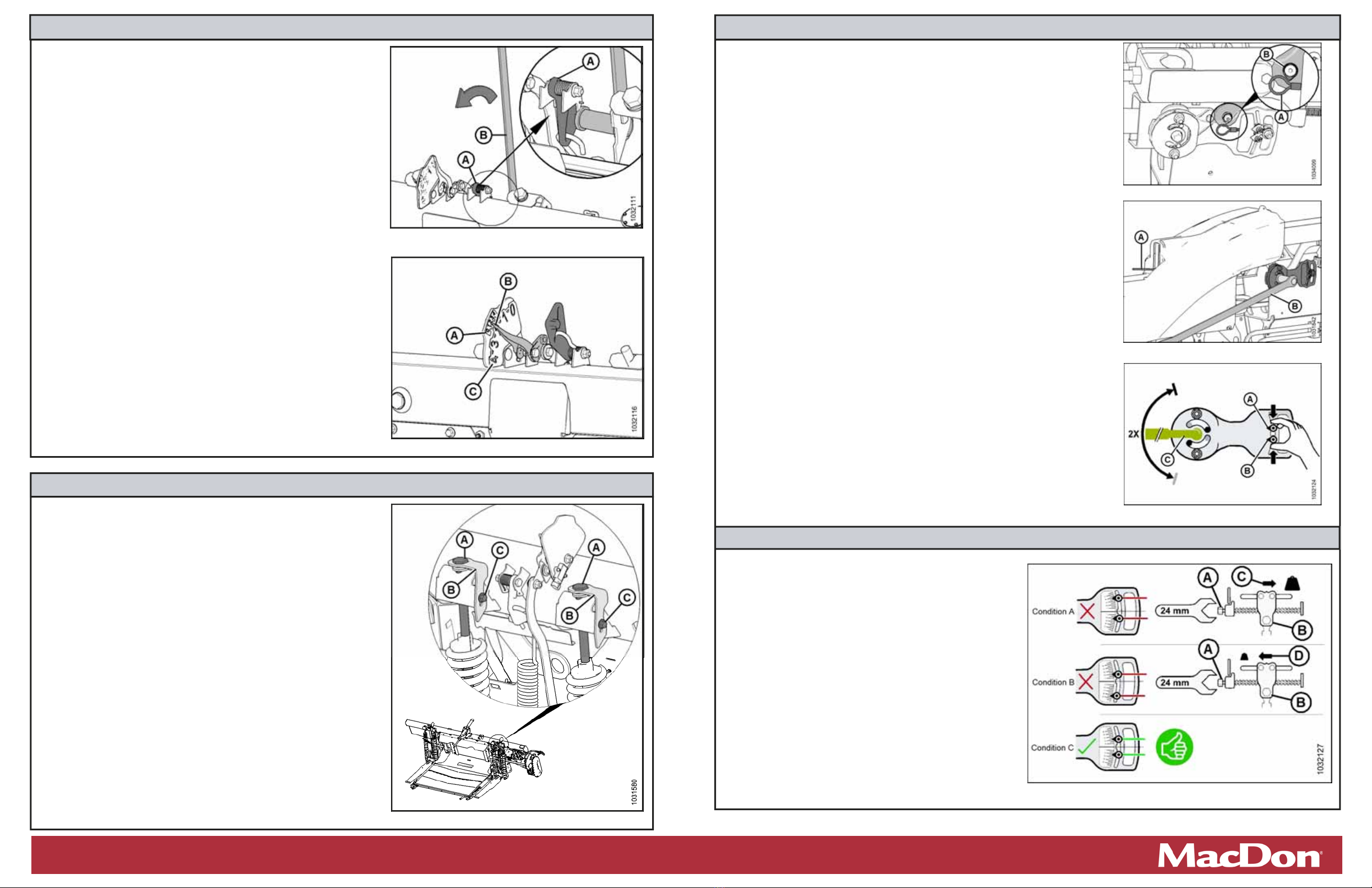

a. Loosen bolts (C), and rotate spring locks (B).

b. To decrease header weight, turn both adjustment bolts (A) clockwise

(decrease number on float seng indicator [FSI]).

c. To increase header weight, turn both adjustment bolts (A)

counterclockwise (increase number on FSI).

NOTE: Ensure float seng indicator readings are equal on both sides

of the float module.

d. Liend of header by hand aer adjusng and recheck reading.

e. Once complete, use the tool and return the float seng lever to its

original locaon.

NOTE: If adequate header float cannot be achieved using all the

available adjustments, an oponal heavy duty spring is available. See

your MacDon Dealer or refer to the parts catalog for ordering

informaon.

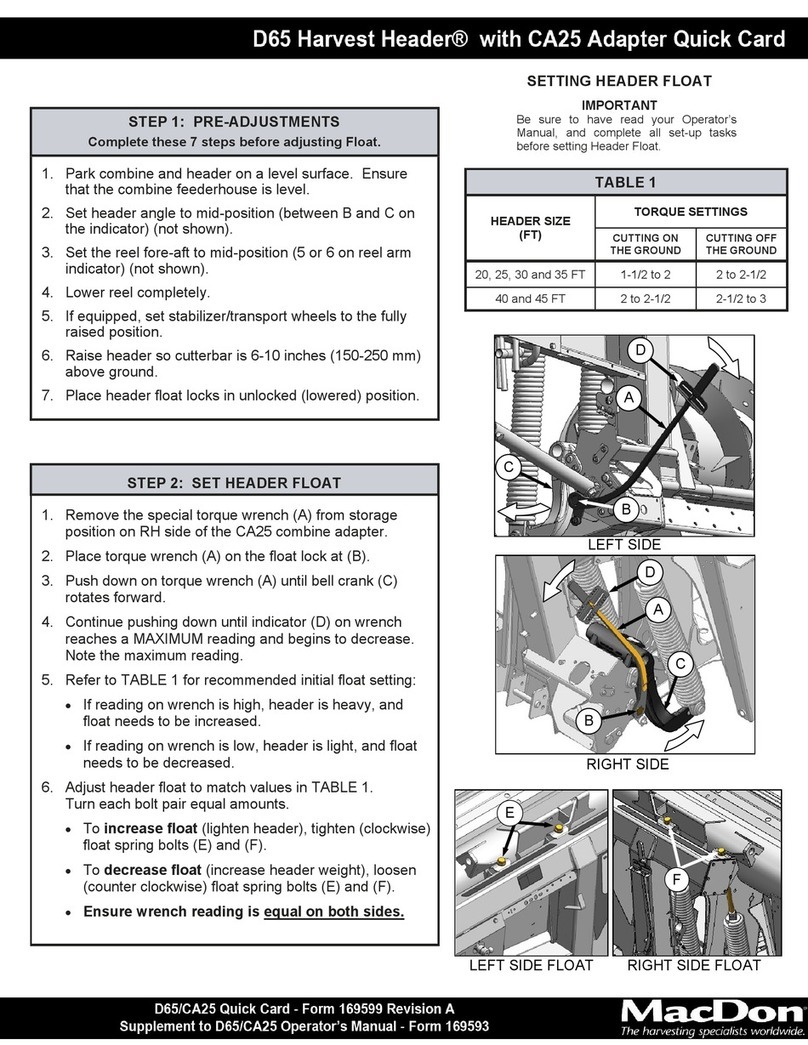

Step 3: Seƫng Header Float

NOTE: Oil reservoir tank made transparent in Figure 4 to show tool

engaged on the float seng lever at the front of the header.

a. Lifloat seng lever (A) by hand to remove any slack.

b. Place tool (B) on the float seng lever. The tool should be slightly

angled towards the front of the header.

c. Pull down on tool (B) towards the back of the header unl lever (A) is

over center and will not return to its original posion. Remove the

tool and repeat on the opposite side. It is important that float seng

levers on both sides are engaged while adjusng.

d. On the side that you are adjusng, move header up and down by

hand, and release to reduce the effect of fricon.

e. Check the numbers in small print (A) on float seng indicator (FSI) for

the current float value. The pointer arm (B) on the FSI should be

on number 2.

• If the reading on FSI is higher than 2, the header is heavy.

• If the reading on FSI is lower than 2, the header is light.

NOTE: The numbers in large print (B) are for the float height indicator

and used when operang the header in the field.

Step 2: Checking Header Float

Figure 5: Checking Float – LeŌSide Shown, View from Rear

Figure 4: Checking Float – LeŌSide Shown, View from Rear

NOTE:

If necessary, set float values to suit crop and field condions. For more

informaon, refer to the header operator’s manual.

NOTE: Before proceeding, the header float must be set properly. Refer to

Step 3: Seng Header Float.

a. Aach flex checker cable (A) to flex checker cable lock (B).

NOTE: Images shown are from the leside.

b. Move spring handle (A) on the side that you are adjusng to the lower (UNLOCK)

posion. You should hear the lock disengaged. If not, use tool (B) to rotate

mechanism so that the lock disengages.

NOTE: Keep the opposite wing locked.

c. On flex checker plate, pinch indicators (A) and (B) together with your fingers.

d. Use tool (C) to rotate flex checker plate up unl pin reaches the end of slot. The

lower indicator (B) will move down to give the first reading.

e. Use tool (C) to rotate flex checker plate down unl pin reaches the end of slot.

The upper indicator (A) will move up to give the second reading.

f. Repeat Steps c and d.

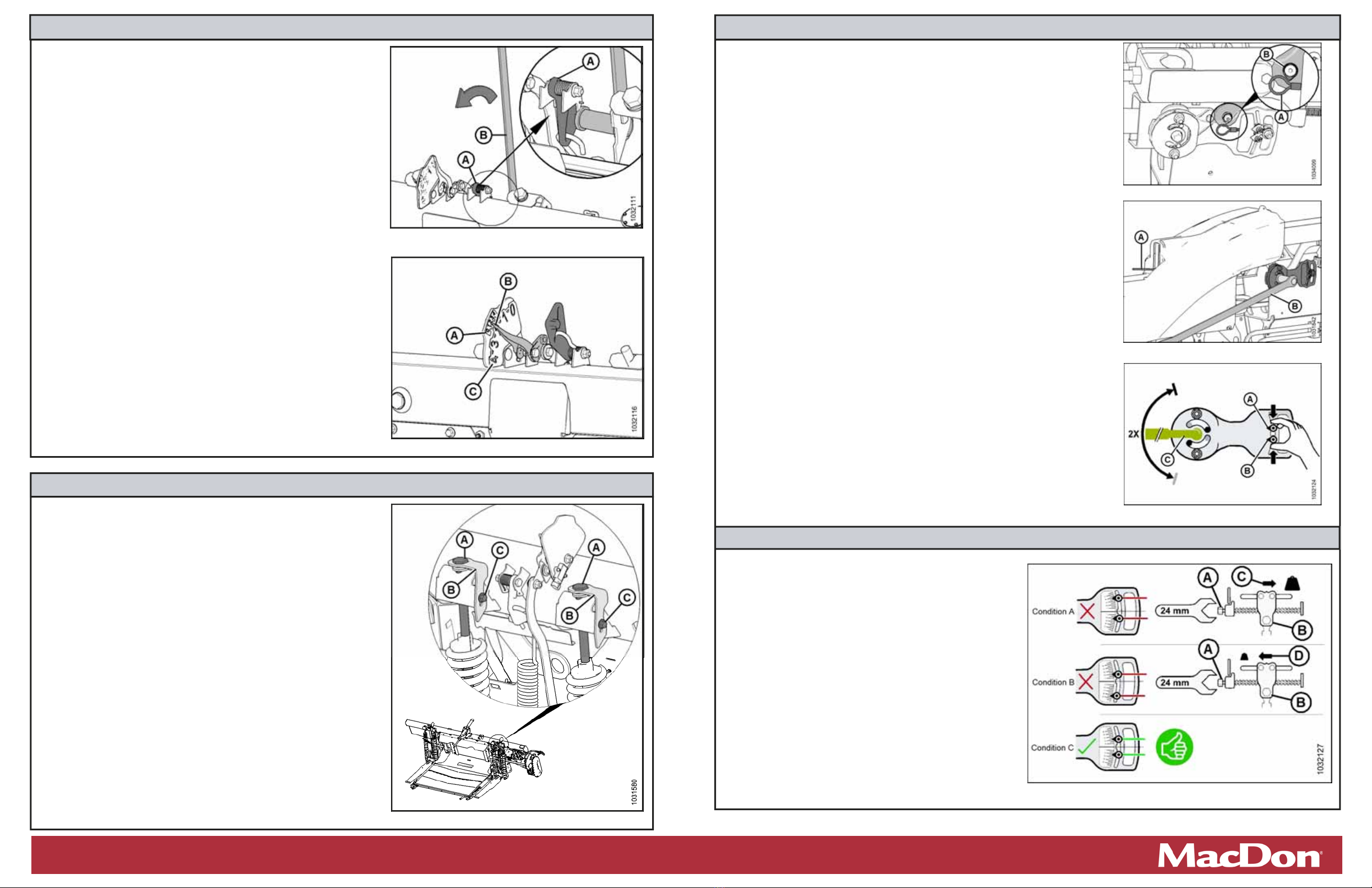

g. Refer to Figure 10 and compare the two readings as follows:

• Condion A –the wing is too light; make wing heavier.

• Condion B –the wing is too heavy; make wing lighter.

• Condion C –wing balance correctly adjusted. Reinstall the linkage cover, and

repeat the procedure on the opposite wing.

Step 4: Checking Wing Balance

a. If the wing is too light (Condion A), make it heavier by

turning adjuster bolt (A) to move clevis (B) in direcon (C).

b. If the wing is too heavy (Condion B), make it lighter by

turning adjuster bolt (A) to move clevis (B) in direcon (D).

c. Recheck wing balance. Adjust as required unl wing is

balanced (Condion C).

d. Move the spring handle to the upper (LOCK) posion.

e. If the lock does not engage, move the wing up and down

with tool unl it locks.

f. Detach the flex checker cable from the flex checker lock.

g. Repeat on the other side.

h. Return the tool to its storage locaon, and reinstall the

linkage cover.

Step 5: AdjusƟng Wing Balance

Figure 8: Wing Balance Linkage

Figure 9: Wing Balance Adjustment

Figure 6: Float Adjustment Bolts – LeŌSide Shown

The Harvesting Specialists. MacDon.com

Figure 10: Wing Balance Adjustment

Figure 7: Flex Checker Cable