Section Summary of Change Internal Use Only

•To avoid bodily injury or death from

unexpected startup of the machine, always

stop the engine and remove the key from

the ignition before leaving the operator’s

seat for any reason.

Added the procedure and pictures for opening

and closing the hood.

3.12.1 Adjusting Pre-cleaner, page 63 Added the procedure, CAUTIONS, and pictures

for opening and closing the right platform.

Tech Pubs

3.17.1 Lubrication Procedure, page 71

•Step 1, page 71

Added step:

•Shut down the engine, and remove the key

from the ignition.

Tech Pubs

3.19.1 Recording Serial Numbers, page 78

•Step 1, page 78

•Figure 3.102, page 78

•Combined two steps into one.

•Changed picture to grayscale.

Tech Pubs

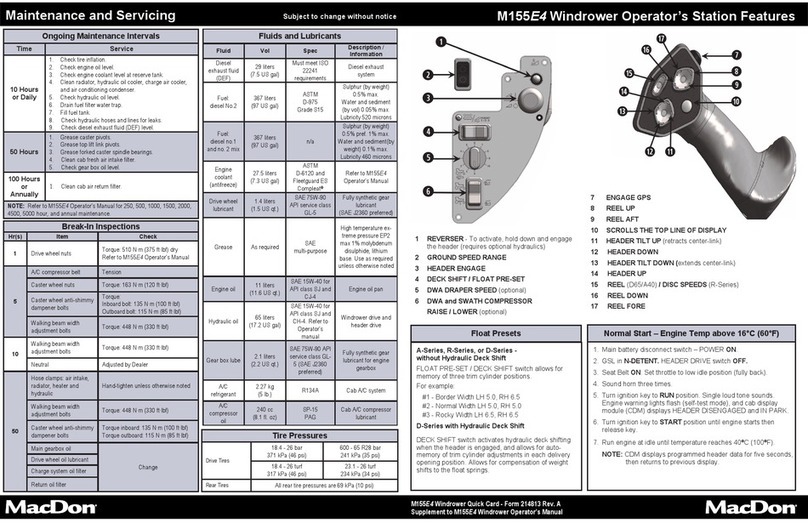

3.19.2 Checking Tire Pressures, page 78

•Table 3.1, page 78

Revised tire pressure information:

•Corrected pressures for bar and turf tires.

•Tire list now includes two types of bar and

turf tires.

Tech Pubs

3.19.3 Adding Tire Ballast, page 79

•Table 3.2, page 79

Added the word “maximum”to the table title. Tech Pubs

3.19.4 Checking Engine Air Intake, page 80 Removed the following WARNING ONLY

because the engine is already off at this point in

the manual:

•To avoid bodily injury or death from

unexpected startup of the machine, always

stop the engine and remove the key from

the ignition before leaving the operator’s

seat for any reason.

Tech Pubs

3.19.5 Checking Hydraulic Oil Level, page 81 Removed the following WARNING ONLY

because the engine is already off at this point in

the manual:

•To avoid bodily injury or death from

unexpected startup of the machine, always

stop the engine and remove the key from

the ignition before leaving the operator’s

seat for any reason.

Tech Pubs

3.19.8 Checking Gearbox Lubricant Level, page

83

Removed the following WARNING ONLY

because the engine is already off at this point in

the manual:

•To avoid bodily injury or death from

unexpected startup of the machine, always

stop the engine and remove the key from

Tech Pubs

215104 vii Revision A