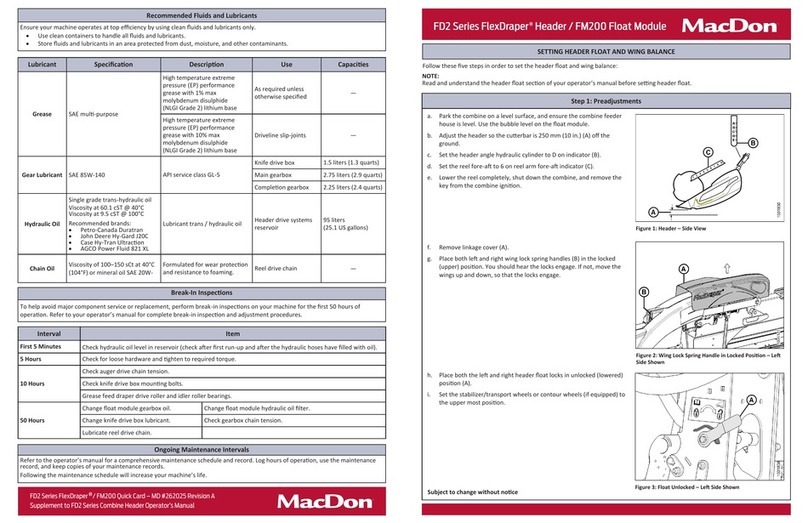

Subject to change without noce

Normal Sengs – Standard & Grass Seed

Disc speed 2100 rpm

Header height 0–1

Header lt

3–4

Adjust to change cut height. Use

skid shoes for high cut heights.

Ground speed Adjust unl condioning

performance is aected.

Adjusng the Windrow – Standard Headers

Rear Bae Posion (Manual) Rear Bae Posion (Electronic) – Oponal for M1 Series

Controls windrow height/width. Directs crop ow that aects width.

1. Remove lynch pin (B).

2. Pull lever (A) inboard to disengage bracket (C):

Move the lever forward (raise bae) for narrow swath.

Move the lever backward (lower bae) for wide swath.

4. Release the lever so the tab engages the notch in bracket (C).

5. Secure the lever with lynch pin (A).

NOTE: Rear Bae Control kit is NOT compable with M205 SP

Windrowers.

The posion of the rear bae can be adjusted from inside the cab.

1. To adjust the bae up and down, press F5 (A) and F6 (B) keys

respecvely.

2. A pop-up will appear on the HPT display for 3 seconds indicang the

bae posion from 0–10 when buons F5/F6 are pressed.

NOTE: The bae posion may be saved using the One-Touch-Return

buons. For more informaon, refer to the windrower operator’s manual.

Bae Deector Fins Forming Shield

Controls material distribuon across windrow.

1. Remove the ns from storage posion (on top of bae).

2. Posion deector n (A) under the bae.

3. Secure with exisng bolt and nut (B) (bolt head facing down).

4. Adjust to approximately 60° angle inward.

5. Torque the nut to 69 Nm (51 lbf·). Repeat on the other side.

NOTE: In large-stemmed crops or while using the DWA, remove the ns

and aach them to the top of the bae for storage.

Controls windrow width and placement.

1. Adjust the forming shield using handle (B) under the windrower.

2. To ensure the windrow is centered, adjust both side deectors (A) to

the same posion.

Windrow Forming Guidelines – Standard Headers

Windrow Width Rear Bae

Posion Forming Shield

3–5 . (0.9–1.5 m) Up Does all windrow formaon. Adjust the sides to

desired width.

5–7 . (1.5–2.1 m) Mid Paral windrow formaon. Adjust sides and bae.

7–8 . (2.1–2.4 m) Down Not in use.

DWA 2nd notch

from top Set at highest seng which does not interfere

with DWA.

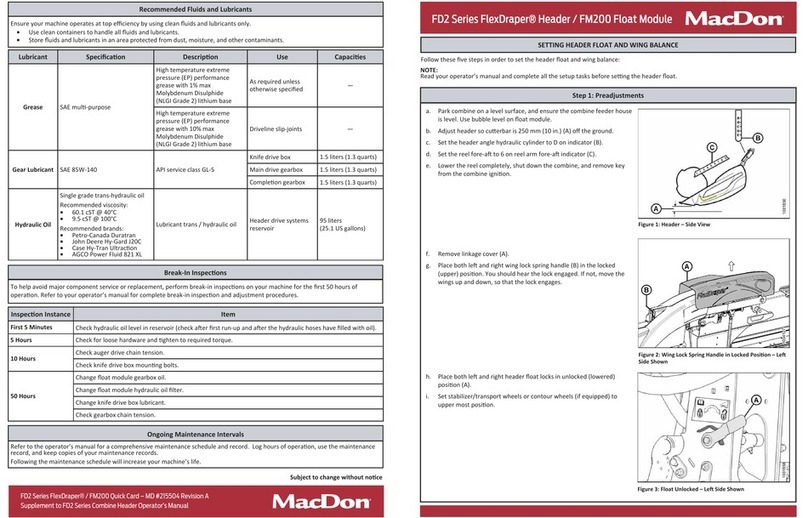

Ongoing Maintenance Intervals

Time Service

Every 10 hours or

daily

Inspect the cuerbar discs.

Inspect the disc blades.

Inspect the accelerators.

Inspect the rock guards.

Inspect the drums.

Check the hydraulic hoses and lines.

Every 25 hours

Lubricate the idler pivot.

Standard headers: Lubricate the upper and

lower driveline universal joints.

Standard headers: Lubricate the roller

condioner and feed roller bearings.

Standard headers: Lubricate the condioner

driveline.

Lubricate the gauge rollers (if equipped).

Every 50 hours Grass seed: Lubricate the grass seed drum

bearings.

Every 100 hours or

Annually

Standard headers: Check the condioner

drive belt tension.

Standard headers: Check the roll ming

gearbox lubricant.

Check the header drive gearbox lubricant.

Every 250 hours

(begins aer the

rst 150 hours of

service)

Standard headers: Change the roll ming

gearbox lubricant.

Change the header drive gearbox lubricant.

Change the cuerbar lubricant.

Lubricate the vercal drivelines at the le and

right driven drums.

Break-In Inspecons

Hour Check

1 Check for loose hardware and ghten to required torque.

5 Check for loose hardware and ghten to required torque.

Check the condioner drive belt tension.

Change the condioner roll ming gearbox lubricant.

50

Change the header drive gearbox lubricant.

100 Check the condioner drive belt tension, and adjust tension

if necessary.

Fluids and Lubricants

Spec Capacity Descripon /

Informaon

Grease

SAE

Mulpur

pose

—

Descripon: High temperature extreme

pressure (EP) performance with 1% max.

Molybdenum Disulphide (NLGI Grade 2)

lithium base

Use: As required unless otherwise

specied

SAE

Mulpur

pose

—

Descripon: High temperature extreme

pressure (EP) performance with 10% max.

Molybdenum Disulphide (NLGI Grade 2)

lithium base

Use: Driveline slip-joints

Gear Lubricant

SAE

80W-90

10 L

10.5 qts (US)

Descripon: High thermal and oxidaon

stability API service class GL-5

Use: 4.9 m (16 .) cuerbar

SAE

80W-

140

0.7 L

0.75 qts (US)

Descripon: Gear lubricant API service

class GL-5

Use: Condioner roll ming gearbox

SAE

80W-

140

1.8 L

1.9 qts (US)

Descripon: Fully Synthec Oil API GL-5

Minimum, SAE J2360 Preferred

Use: Header drive 90° gearbox