MAINTENANCE

CAUTION

Before carrying out any maintenance disconnect the air

supply and release the fluid pressure in the system.

Inspect your oil pump and associated hoses weekly for any

signs of damage. Replace any suspect or damaged parts

or components as required.

PUMP DISASSEMBLY

Note: Disconnect the air supply and release fluid

pressure.

The R1000 pump has been designed to allow the air motor

assembly, and air seal (10) to be serviced without removing

the pump from the installation.

To service theAir Motor and Piston Rod Seal

without removing pump from the installation:

1) Disconnect the air supply and release oil line pressure.

3) Pull the air motor and piston rod assembly upwards to

to allow easy access the air motor bolts (53).

7) Remove the three air valve screws (2), washers (3) and

spacers (4) from the air valve assembly, then remove air

valve cap (49).

5) Lift up the top adaptor (9) to expose the exhaust holes

located on the piston rod (41).

6) To retain the piston rod (41), insert the correct size steel

bar or pin punch into one of the exhaust holes on the

piston rod (41).

8) Unscrew the piston rod bolt (48), and remove the air

valve assembly.

Note: Ensure you do not damage piston rod (41) during

disassembly or assembly.

9) Remove the top adapter assembly (9,10,53,54,55,57)

from the piston rod.

10) Carefully remove the air seal (10), o’ring (57) and o’rings

(55) from the top adapter (9).

11) Remove body (11) and silencer (40).

12) Clean and inspect all parts. Pay special attention to the

main oil seal assembly as this can be easily damaged.

Replace any suspect, worn or damaged components.

Note: Use Loctite 222 (or similar retaining compound) on

the piston rod bolt thread (48) and the three air valve

screws (2) when re-assembling air motor.

4) Use a 6mm Allen key to unscrew the 4 air motor bolts

(53).

13) Assembly is the reversal of disassembly.

Note: Use Loctite 222 (or similar retaining compound) on

the piston rod bolt thread (48) and the three Allen screws

(2) when re-assembling the air motor.

COMPLETE PUMP DISASSEMBLY

1) Disconnect air supply and release oil line pressure.

2) Remove oil discharge hose from pump outlet.

3) Withdraw pump from the oil drum/tank. (Use a clean

bench to carry out maintenance).

4) Hold the bottom adaptor firmly in a vice and carefully

unscrew and remove the pump tube (20) assembly.

Note:Care should be taken not damageairmotor housing

during disassembly.

5) For air motor disassembly see previous section “Pump

Disassembly”, To service the air motor and piston rod

seal section follow items 2 - 12 on this page.

6) Using a suitable size pin punch (1/8”) remove the roll pin

(36) from the Piston rod (41).

7) Unscrew and remove the joining pin (35), valve housing

(23) and piston assembly from the piston rod (41).

9) Remove the piston rod (41) from the bottom adapter (15).

10) Unscrew and remove and the oil seal assembly (14).

11) Remove foot valve assembly (28) from the pump tube

(20).

12) Dismantle foot valve assembly.

PUMP ASSEMBLY

1) Clean and inspect all parts. Replace any, suspect, worn

or damaged parts.

2) Ensure that all parts have the correct orientation. If

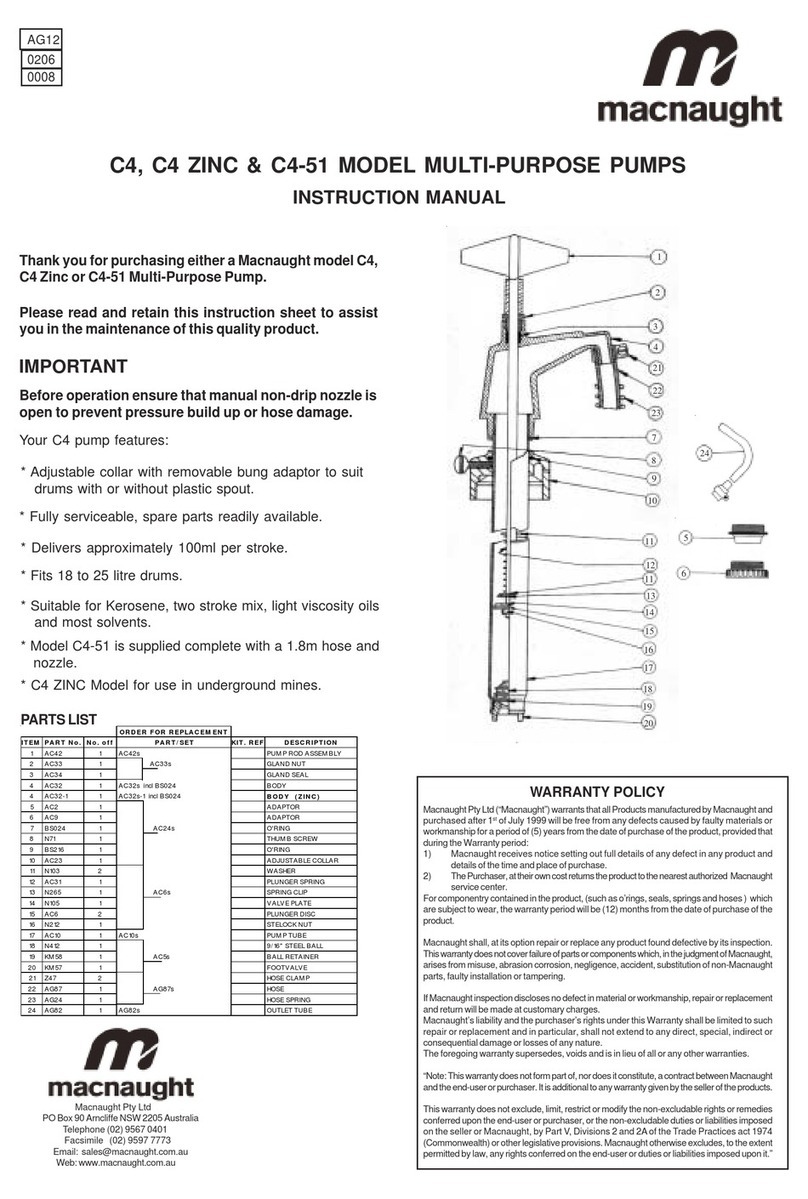

parts are assembled upside down, the pump will not

work. Check the parts diagram for correct orientation.

2) Either use a strap pipe wrench to carefully unscrew and

remove the air motor housing (50), or use two correct

size steel bars or pin punches and insert them into the

holes located on the top of the air motor cap (1). Hold

both steel bars or pin punches in position. Place a screw

driver in between the two bars or punches and unscrew

the air motor cap anti-clockwise.

Use Loctite 222 (or similar retaining compound) when

assembling the pump piston (26) to the valve housing

(23).

Ensure correct orientation when fitting the oil seal (38),

be careful you do not damage the seal during assembly.

8) Dismantle the valve housing (23) and piston assembly

(26).

3) Assembly of the pump is a reversal of the disassembly

procedure.

4) Fit the pump to your drum/tank and re-connect the oil

hose and air supply. Open dispensing nozzle to ensure

correct operation.

2

Do not run the pump dry. Remember to switch off the air

supplyif the pump isnot being used for extendedperiods.

(e.g. at the end of each working day)

CAUTION