Energy Meter microCLIMA

Installation and Operating Instructions V. 1.03 October’06

microCLIMA

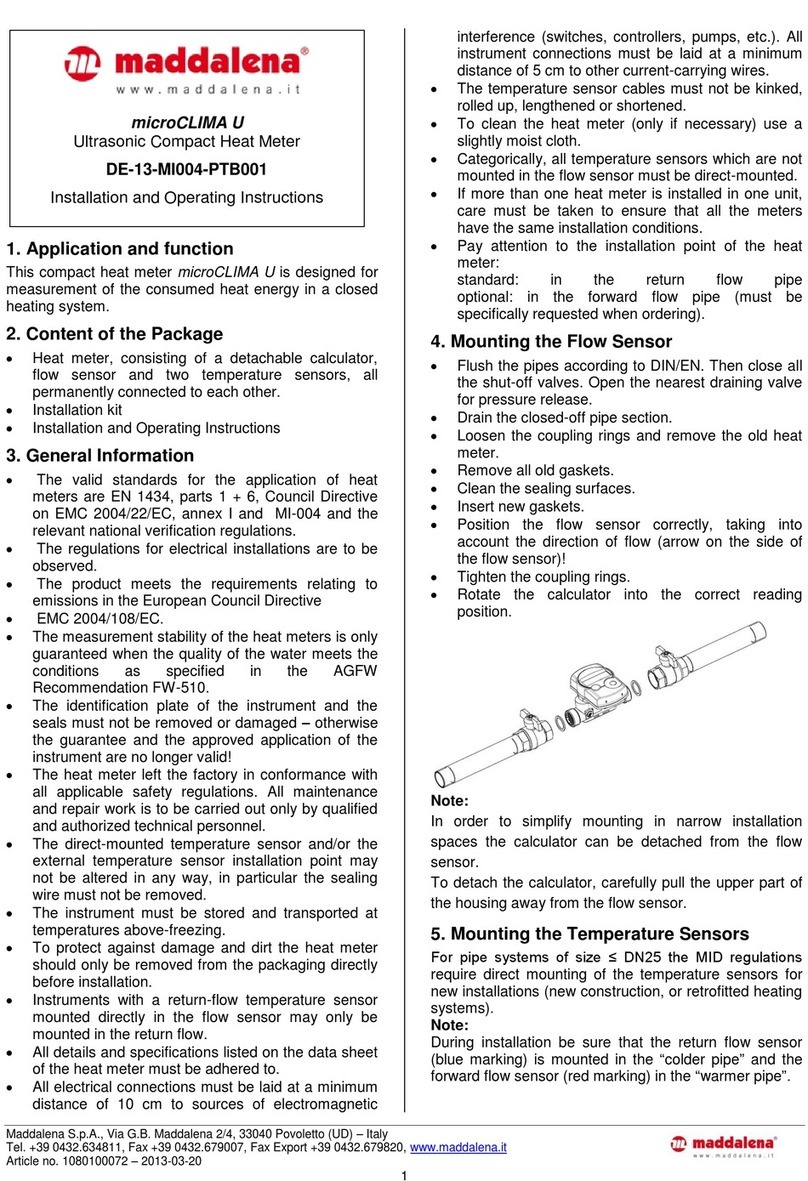

3. Mounting theTemperatureSensors

3.1. Installation in temperaturepocket

- PlacetheO-ring in themiddle

groove. Slide the sealing

screw nut upto the O-ring.

- Holding the screw nut in

place,insertthe sensor into

the ball valve and tighten the

screw nut.

3.2. Installation in a ballvalve

- Removethe blind cap orplug

and itsgasket. Checkthat all

surfacesare clean.

- PlacetheO-ring in the groove

closest to the tip ofthe

sensor. Slide the sealing

screw nut upto the O-ring.

- Holding the screw nut in

place,insertthe sensor into

the ball valve and tighten the

screw nut.

4. Start of Operation

- Slowlyopen the shut-off valves

- Checkfor leakage and proper functioning

- Clean the calculator

After confirming that the heat meter is functioning

properly,insert and tighten the sealing wires for

the temperature sensors and the heat meter itself.

When replacing ameter at the end of averification

periodnote the meter readings and the serial

numbersof the old andnew meters.

Please also checkthe following points:

• Is the heat meter the appropriate size?

• Is the heating system in operation?

• Are the shut-off valves open?

• Is the heating system clear(dirtfiltersnot

clogged)?

• Arethe temperaturesensorssealed with

wires(to avoid tampering)?

• Is the directionalarrow on the flow sensor

in the correct direction?

• Is a flow volume displayed?

• Is aplausible temperature difference dis-

played?

• For instrumentswith twoexternal temp-

eraturesensors, isthe forward flow sensor

(red) in the forward flow and the returnflow

sensor(blue)in return flowpipe?

• For instrumentswith abuilt-in return flow

temperaturesensor, is the flow sensor

mounted in thereturn flow?

5. TechnicalData

Type 0.6 1.5 2.5

Flow sensor

Nominal flow m3/h 0.6 1.5 2.5

Maximum flow m3/h 1.2 3.0 5.0

Nominalpressure bar 10

Low flow horizontal

threshold vertical l/h 3.5

4 7

7 10

10

Temperature range °C 15…90

Mounting position any

Calculator

Ambient temperature °C 5…55

Temperature range °C 1…130

Temperature difference K 3…100

Powersupply 3 V, Lithium

Operating life Years

(10+ 1 optional)

Datastorage E²PROM, daily

Display 8-digit

Infrared

M-bus (optional)

Interfaces

Pulse output

(optional)

Temperaturesensors

Type Platinum precision

resistor

Connection 2-wire technique

Diameter mm 5.0(optional 5.2)

Cable length m 1.5(optional 3.0)

6. The DisplaySet-up

The calculatorhasaliquid crystal displaywith8

digitsand special characters.The valuesthatcan

be shown are divided into three displayloops.

• main loop

• technician’s loop

• statistics loop

All dataisretrieved using the keynextto thedis-

play.The standard displayhasbeen set to perma-

nentlyshowthe totalheat quantityconsumed since

the meter wasput into operation.

At the start you areautomaticallyin the main loop.

Bypressingthe keylonger than 4seconds you

change to the next loop. Keep the keypressed

until youreach the desired information loop.

To change the informationdisplaywithin a loop,

simplygive ashort pressto the key.In thisway,

you can scan all the information in the loop.

Afteroneminuteof non-use, the displayreturns to

the total heat quantity, the standard display.