2/5

LH71/LH72 Segmented error compensation Setting manual

To use the segmented error compensation function, it is necessary to measure the amount of error with the distance actually traveled

with respect to the count value of the measuring unit. To measure the actual distance traveled, use a laser interferometer or the like. The

segmented error function can be used in combination with the scale with built in reference point. The base point for the segmented error

compensation is based on the reference point position of the scale (0 mm).

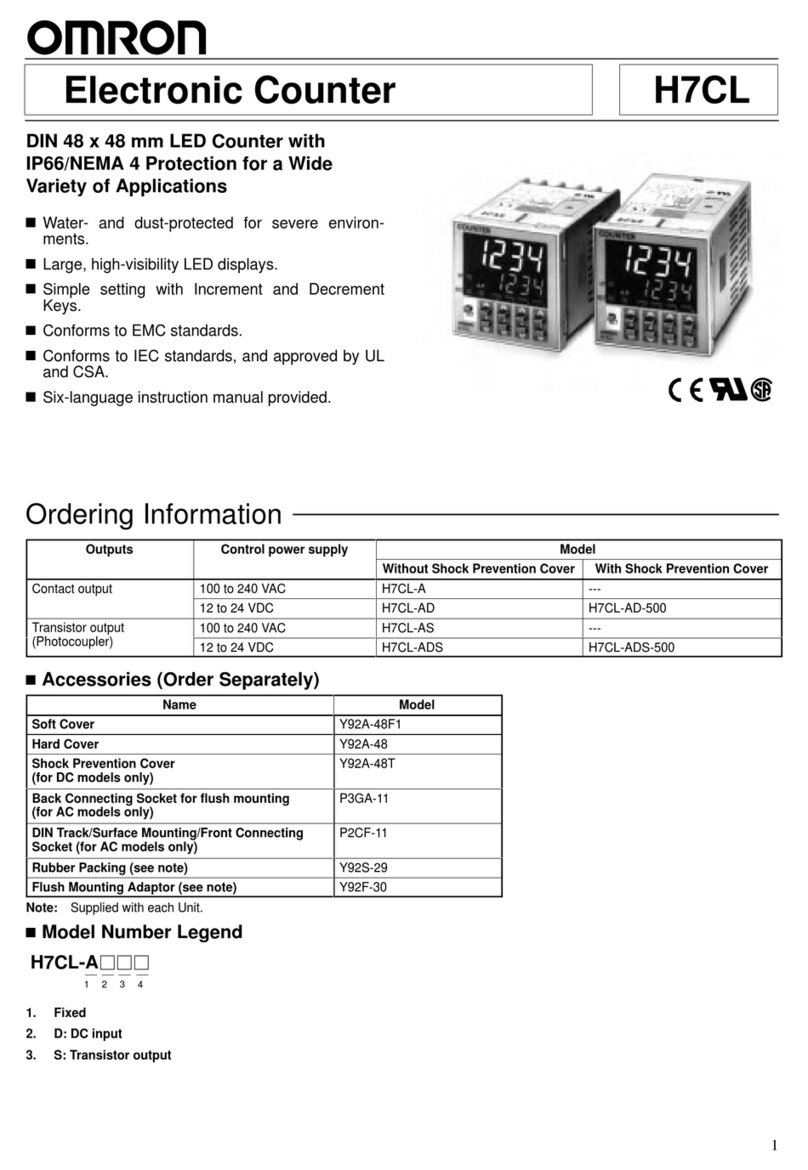

Changing points Distance Error amount

P1 l 1 ε1

P2 l 2 ε2

P3 l 3 ε3

P4 l 4 ε4

P5 l 5 ε5

Error amount :ε=εM-εC

εM:Master (laser interferometer, etc.)

εC: Count value of display unit

Actually move the stage (or object) and collect the entire error data. Create an error curve from the data and narrow

down the changing points (compensation points) to 32 points or less. If there are two or more axes, consider using

the average value for each axis or narrowing down to the data of frequently used positions.

The measurement range that can correct the segmented

error compensation is the range of 7 digits displayed.

3. Setting of segmented error compensation function

The range of segmented error compensation depends on the minimum resolution

used. In addition, the maximum number of points that can be corrected for section

error is 32 points excluding the reference point. The maximum total compensation

amount is ±600um. The count value of the measuring unit with respect to the actual

distance traveled is affected by the direction of movement of the table and the

change in attitude of the machine due to the movement of the stage.

Measurement unit with built in reference point

Reference point

Resolution Correctable range Compensation

points

0.1um ±999.9999 mm (App. ±1m) Up to 32 points

(Excluding

reference points)

0.5um ±999.9995 mm (App. ±1m)

1.0um ±9999.999 mm (App. ±10m)

10um ±99999.99 mm (App. ±100m)

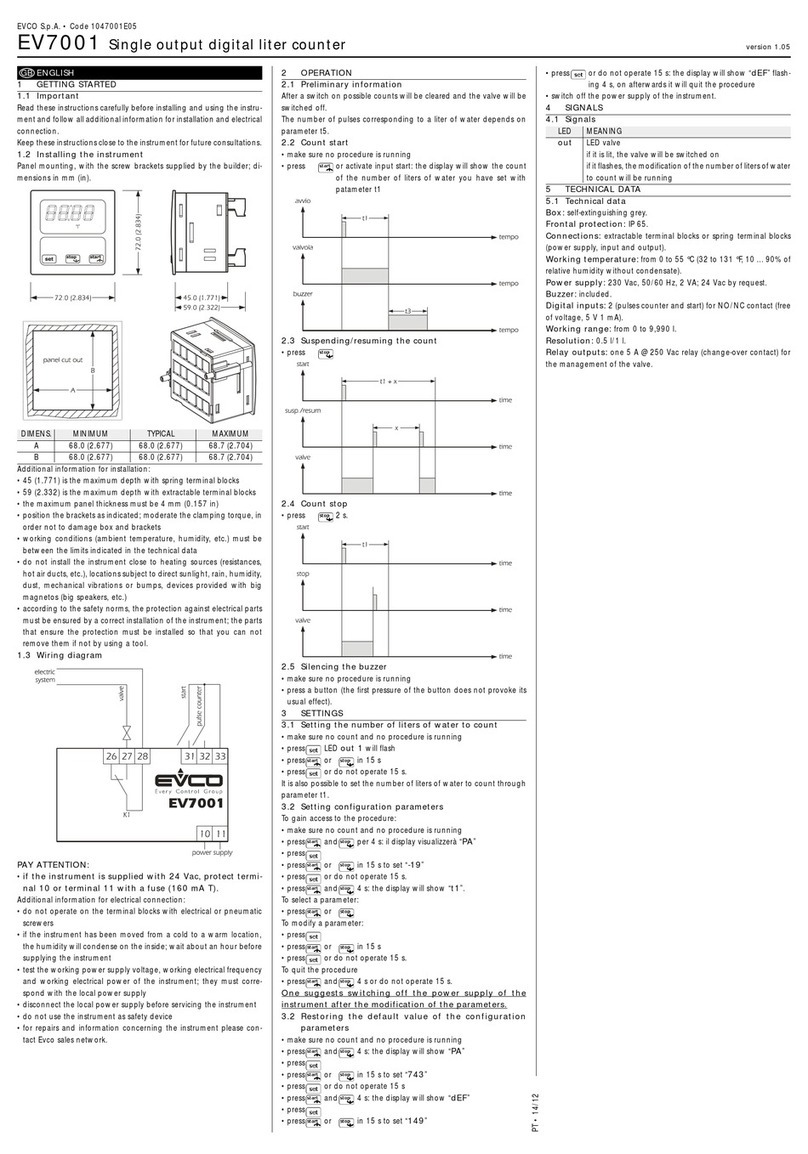

Drive range matrix on the X-Y axis plane

Reference point position: 0

A finer error curve can be obtained by making the

sampling interval for acquiring error data finer.

Narrow down the changing points of the error curve to 32

points or less. Number from 1 in order from the minus side

or the smallest value.

(Excluding the reference point position)

Measured error curve

Error curve of linear error

Laser interferometer

Moving fixed Laser-head

X axis

Stage

Y axis

If the slope of the error curve is a straight curve,

the linear error compensation function may be

sufficient instead of the segmented error

compensation function. When the changing point is 5 points

Y1

Y2

Y3

X1 X2 X3

+

+

Measurement of mechanical error

Sampling pitch

In the case of X and Y axes,

6 measurements are required,

even if at least the left, right,

and center of each axis are

taken into consideration.

STEP 1

Error amount ε

Error amount ε

Moving distance

Distance traveled based

on the reference point

Distance traveled

based on the

reference point

(l)

Reference point position: 0

Error amount (ε)

l 1

l 2 l 3

l 4

l 5

ε1ε2

ε3

ε4

ε5

P 1

P 2

P 3

P 4

P 5

X

Y1 Data1

Y2 Data2

Y3 data3

X1 X2 X3

Ydata4 data5 data6