6 Technical data

4

• with a fireproof installation shaft for ER-UPB

housings;

• if unit is completely installed;

• with permissible air filters (Permitted exhaust air

systems);

• with the outside air openings stated in the plan-

ning documents;

• Centro-E/Centro-H: pressure controller for the

centralised fan required.

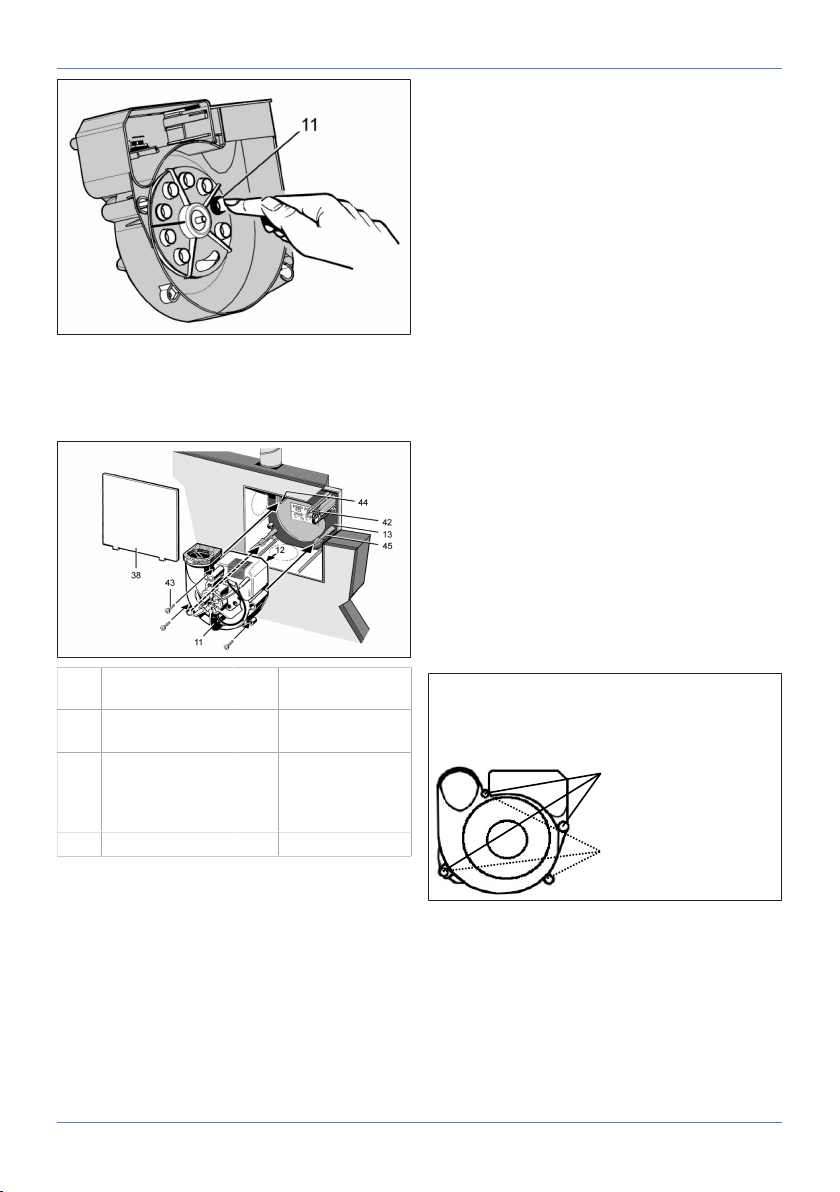

5.5 Exhaust air elements

Centro-M

Manual model. For use in systems with jointly

variable volumetric flows. Fixed air volume setting

by pushing out sealing plugs in each exhaust air

element.

Centro-E

Electric model. With electro-thermal servomotor

for switching between basic and demand-based

ventilation. Fixed air volume setting of the basic

ventilation by pushing out sealing plugs in each

exhaust air element. Demand-based ventilation

automatically via servomotor.

Centro-H

Model with automatic humidity control. Barrier-

free product as the fan switches itself on and off

automatically. With fixed air volume setting of the

basic ventilation by pushing out sealing plugs in

each exhaust air element. Demand-based ventila-

tion automatically or via a switch (for example

light switch).

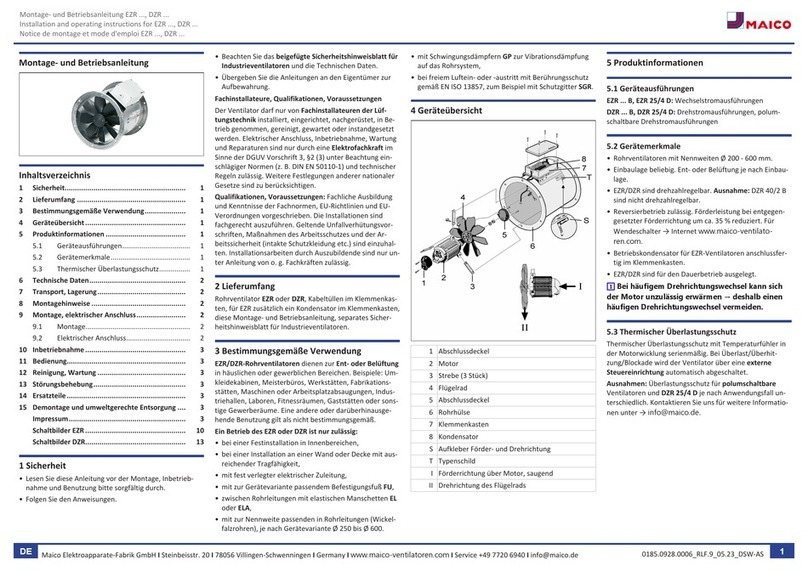

5.6 Product features

• Fire protection identical with Maico ER single-

room air extraction, see ER UP/Centro main in-

structions.

• No cold smoke barriers required.

• No additional telephony sound absorbers re-

quired.

• It is possible to rotate the cover by ±5° (for

housings which have been fitted at an angle).

• Control circuit board in spiral housing for

Centro-H.

• Centro-H not approved for second room con-

nection.

• The flush-mounted housing has easy to install

snap-in exhaust air elements.

• Quick installation of E and H units thanks to

electrical plug connection in flush-mounted

housing.

• Shaft level difference according to DIN 4109,

tested by IAB Oberursel (The Institute for

Acoustics and Building Physics in Germany).

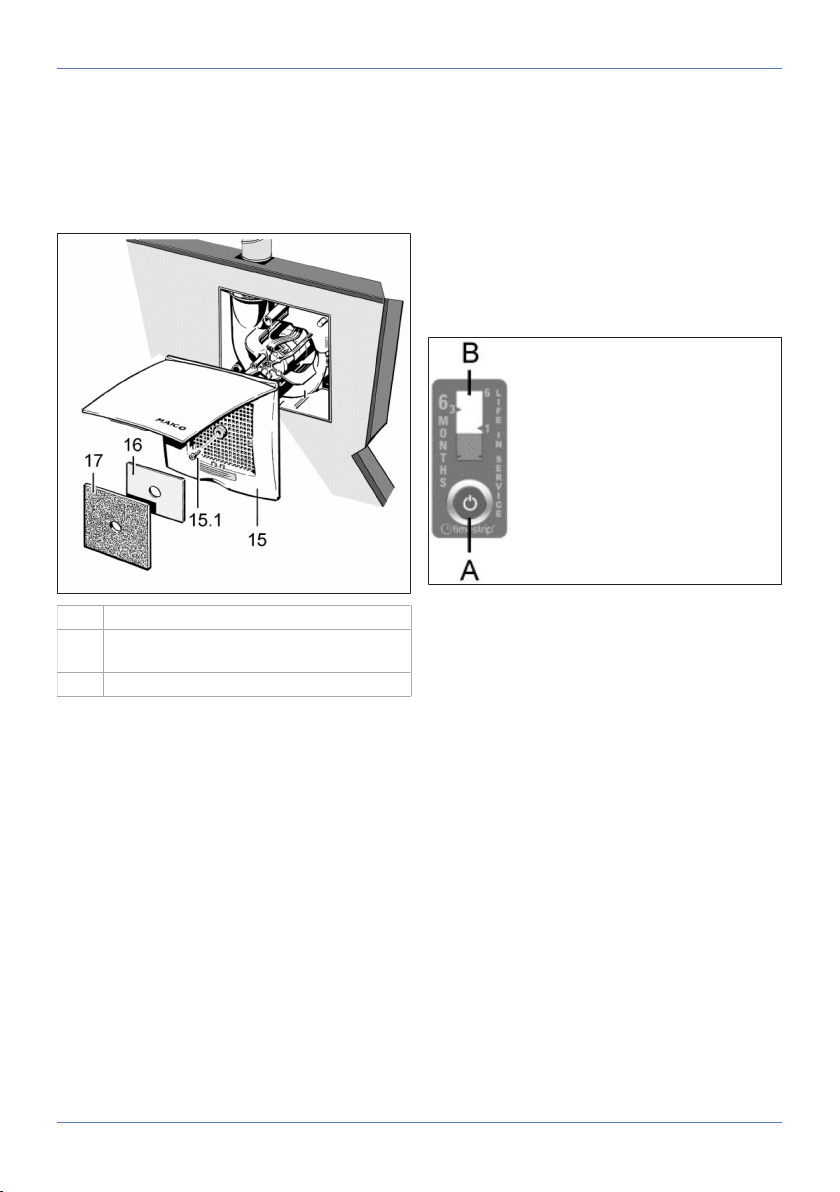

• Cover with exhaust air filter and time strip. Air

filters are to be changed regularly when filter

change is indicated (time strip).

• Trouble-free filter change without tools.

• Centro-M with protection class II. Installation

also permissible with water jets (DIN VDE

0100-701, area 1).

The time strip is visibly attached to a location

of your choice (e.g. next to the cover) and after

the filter change interval has elapsed, it can be

disposed of in the domestic waste. Do not affix

the time strip under the cover. New time strips are

included in the scope of delivery of the exchange

air filter.

6 Technical data

6.1 Environmental conditions and op-

erating limits

• Permissible maximum temperature of air me-

dium + 40 °C.

• The air supply to the home must be set up so

that virtually no air can flow into the living areas

from the kitchen, bathroom or WC.

• Minimum volumetric flow per exhaust air ele-

ment 30 m³/h.

• A room from which the air is to be extracted

must be fitted with a non-closable, free supply

air cross section of at least 150cm², e.g. with

MLK door ventilation grille.

• Centro-E and Centro-H with resistance to inter-

ference according to EN55014-2 – 1000 to

4000 V depending on pulse type and energy

component. When operating with fluorescent

tubes, these values can be exceeded. In this

case, additional interference suppression meas-

ures (L, C or RC modules, protection diodes,

varistors) are required.

6.2 Regulations for operation with

fireplaces

Sufficient supply air intake must be ensured

during operation with air-ventilated fireplaces.

The maximum permitted pressure difference per

residential unit is 4 Pa.

The unit may only be installed in residential units

with air-ventilated fireplaces under the following

conditions: