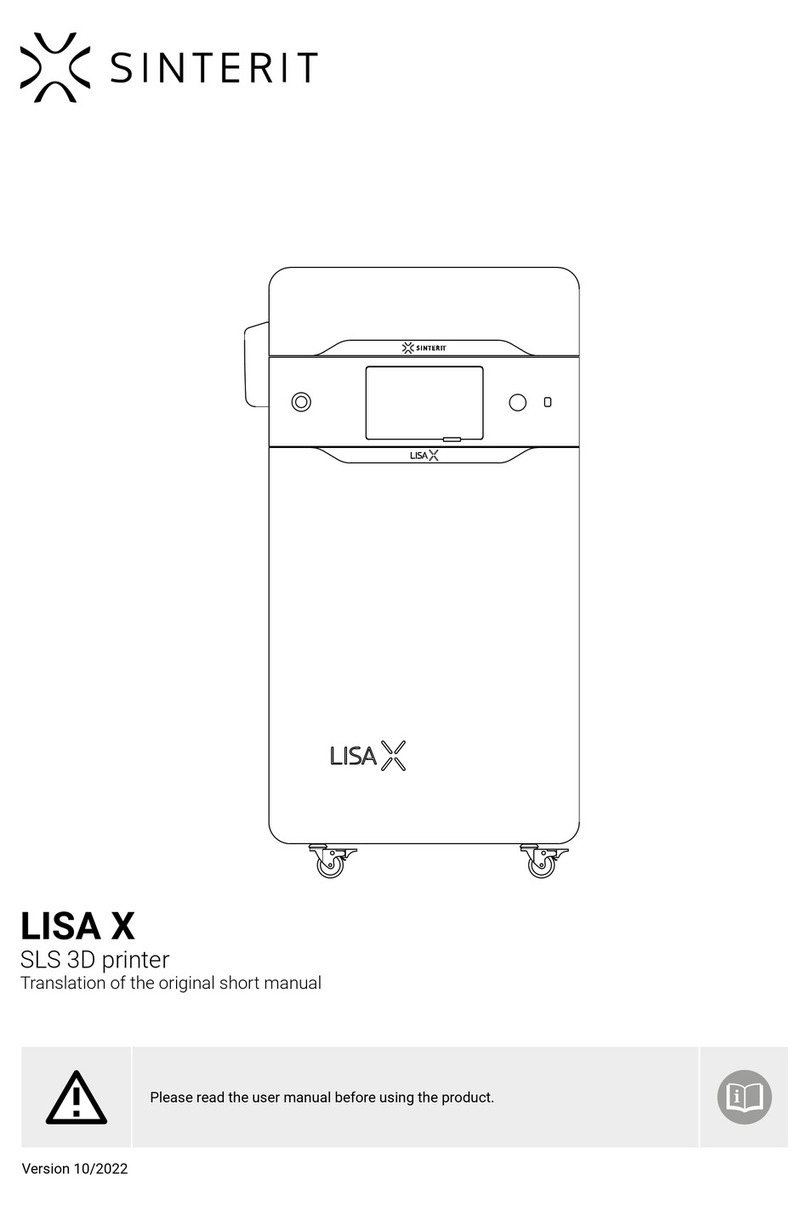

SINTERIT LISA User manual

Sinterit Lisa

USER MANUAL

Read the instruction manual before starting the device

Version 1.5

1 Sinterit Lisa USER MANUAL

Industrial quality SLS 3D printing right from your

desktop!

How the Lisa printer works:

The Sinterit Lisa desktop 3D printer uses selective laser sintering technology to produce your

prints. Within its chambers, a powdered material is heated up and turned into a solid mass

with a concentrated laser beam. Layers of polymer powder are placed onto the printer's work

platform, where they are selectively sintered, giving perfect industrial-quality prints:

● small elements with details,

● complicated structures,

● complex solid shapes with moving parts in one go,

● simultaneous multi-objects prints,

● extremely durable models against unfavourable conditions (such as temperature),

● solid, lightweight parts,

● and much, much more..

Lisa’s main features:

● Precision: high accuracy of prints thanks to layer thickness from 0.075 [mm],

● Plug-and-play: no installation or calibration needed,

● 4-inch touch screen: for a friendlier user experience,

● Wi-Fi connectivity: to track the printing process,

● Easy to operate,

● Dedicated software suite - Sinterit Studio 2018 supporting formats: STL, OBJ, 3DS,

FBX, DAE and 3MF,

● Economic: powder recovery system allows printing with up to 100% recycled powder,

● Startup time: 45-60 min.

Printer ideal for:

● Functional testing,

● Rapid prototyping,

● Low volume manufacturing,

● High-heat and chemical resistant applications.

2 Sinterit Lisa USER MANUAL

Table of content

Table of content

1. Dictionary 5

2. Marking text conventions used in the document 6

3. Sinterit Lisa 3D printer 8

A. Description 8

B. Specification 11

C. Contents of the Sinterit Lisa pack 13

D. Parameters - print design guide 14

4. Installation of the printer 15

A. Environment and place of installation 15

B. Power supply: 16

5. Sinterit Studio software - installation 17

6. Initial startup of the device after delivery 19

7. Printer’s connection to the wi-fi network 20

8. Preparing the device to print 22

9. Printing - STANDARD MODE 27

A. Information and tasks while printing 34

B. Finishing the print 36

C. Cleaning the printer 41

10. Printing - ADVANCED MODE 46

A. Printing in ADVANCED MODE: automated version 47

B. Printing in ADVANCED MODE: manual version 50

C. Information and tasks while printing 52

D. Finishing the print in ADVANCED MODE 53

11. Cleaning the prints 57

Painting and lacquering 60

12. Maintenance and service of the Sinterit Lisa Printer 60

A. Laser protective glass - replacement 61

B. Cleaning of laser protective glass 63

C. Cleaning the surface under the Beds 64

D. Replacement of infrared heating units placed around the protecting glass. 66

E. Changing the Recoater wire 66

F. Technical support 68

3 Sinterit Lisa USER MANUAL

13. Working processes with the materials 68

A. Supplies information 68

B. General information 69

C. Materials in Sinterit Studio 72

D. Materials in the Sinterit Lisa Printer 73

E. Cleaning the machine and changing the powder 73

14. General legal information 74

15. Disclaimer 75

16. Trademarks 75

17. Software license agreement 75

18. Terms of warranty 75

19. Packaging / repackaging guide 76

A. Preparing of the machine 77

B. Packaging 77

C. Packaging if the original packaging is no longer available or damaged 78

4 Sinterit Lisa USER MANUAL

1.Dictionary

The following terms and forms have been adopted and used in the manual.

1. SINTERIT Lisa 3D PRINTER (3D printer, printer, device, product) –

a selective laser sintering (SLS) device used in additive manufacturing (AM)

processes. Device dedicated for professional and quick manufacturing of three

dimensional (3D) models of spatial objects.

2. SINTERIT STUDIO – dedicated software for the Sinterit Lisa Printer. Sitnerit Studio

as a desktop application allows to prepare 3D models (set them in the printable area -

called Print Bed) and track the print status of the printer during the printing process.

3. PA12 SMOOTH (PA12, polyamide powder, nylon powder, PA powder, PA12 powder,

powder) – a polyamide powder with the granulation at 20-100 micrometers. Black and

smooth powder is suitable for printing detailed objects, rigid and extremely durable

against unfavourable conditions (such as temperature). Due to its mechanical

strength and heat resistance, dedicated for functional prototypes or end-use parts.

4. FLEXA BLACK, FLEXA GREY (Flexa) – a powder from the Thermoplastic

Polyurethane Elastomers (TPU) group. Elastic, similar in its properties to rubber.

Possesses good formability properties (returns to its initial shape). Suppresses hits

and shocks well.

5. RECOATER – a Recoater in the form of a roller, moving on a guide bar by means

of a wire. Used to transfer the powder from the Source Bed to the Print Bed during

the printing process.

6. FEED BED (Source, Source Bed) – a chamber storing new, unsintered powder.

7. PRINT BED – a chamber where the sintering of powder takes place, creating the

print.

8. OVERFLOW BIN – a chamber used to collect the excess unsintered powder,

transferred from the Source Bed to the Print Bed by the Recoater.

9. FRESH POWDER (PA12 Smooth Fresh Powder - container no. 1) – virgin powder,

used for refreshing, needs to be mixed with the used powder in correct proportions.

Fresh Powder is not suitable for printing (the print may not be successful).

10. PRINT READY POWDER (PA12 Smooth Print Ready Powder - container no. 2) –

powder ready to be used by the printer.

11. USED POWDER all the unsintered powder that remains after the printing and

cleaning process. Suitable for printing if we are using Flexa Black or Grey. If using

PA12 - suitable for printing after refreshing by 30 % of Fresh Powder.

5 Sinterit Lisa USER MANUAL

2. Marking text conventions used in the document

Listed below are descriptions of the symbols used on the device. They constitute a warning

or convey the information to protect the user, other individuals and surrounding objects, and

ensure correct and safe use of the device.

WARNING!

An inevitably dangerous situation which can result in serious injury or even

death, if not mitigated. Initiation, omission of a specific procedure or

inattention can cause severe physical injury to the user.

ATTENTION!

Initiation or omission of a specific procedure can cause physical damage to

the equipment or the user.

WARNING!

Risk of electric shock which can be fatal or cause severe burns. An inevitably

dangerous situation which can result in serious injury or even death, if not

mitigated. Before working with any equipment, you should be aware of the

dangers associated with the flow of electric current, and become familiar with

the standard procedures to prevent accidents.

ATTENTION!

Risk of electric shock.

CAUTION!

High temperature – do not touch. Excess heat dissipation can cause burns.

CAUTION!

IR laser radiations. Looking directly into the laser beam can cause blindness

and skin burns. The laser emits infrared radiation (Infrared, IR), which is

invisible to humans. Avoid eye or skin exposure to direct or scattered

radiation. Do not stare into the beam or view with optical instruments.

CAUTION!

Beware of intense light.

CAUTION!

Beware of moving parts which can crush hands.

6 Sinterit Lisa USER MANUAL

CAUTION!

Beware of sharp edges which can cause body cuts and injury.

CAUTION!

Beware of moving parts which can snag and pull.

WARNING!

Avoid fire! PA12 powder dust is flammable.

STOP!

Action prohibited.

IMPORTANT!

Information essential to correctly perform a specific task.

ATTENTION!

It is necessary to wear protective gloves. Mandatory action when working with

powder.

ATTENTION!

It is necessary to wear protective face mask. Mandatory when working with

powder.

IMPORTANT!

You must read the instructions before taking action.

7 Sinterit Lisa USER MANUAL

3. Sinterit Lisa 3D printer

A. Description

1.Printer lid / 2.Opening lid handle / 3.Overflow bin / 4.Front panel / 5.USB port / 6.Safety key switch /

7.Safety button (E-STOP)

Image. View of the printer's right side.

1.Front panel / 2.LCD panel - Camera view / 3.Ventilator

Image. Front view and rear view of the printer.

8 Sinterit Lisa USER MANUAL

Image. View of the printer’s left and top side.

1.Lid hinges / 2.Power socket / 3.Power button / 4.Viewing window in the lid

1.Infrared heaters (long, red) / 2.Laser protective glass / 3.Laser system / 4. split pin / 5.Infrared

heaters (short, white) / 4 pieces on each side of the laser protective glass

Image. View of the printer's lid inner side.

9 Sinterit Lisa USER MANUAL

1.Recoater’s cable / 2.Recoater slide guide / 3.Overflow Bin’s gap / 4.Print Bed / 5.Recoater /

6.Source Bed

Image. View of the printer’s internal chamber.

1.Camera recording a working printer with closed lid / 2.Pyrometer / 3.Pyrometer

Image. Inside view of the printer (the location of pyrometers and camera).

10 Sinterit Lisa USER MANUAL

B. Specification

GENERAL

Category

Desktop 3D printer

Printing technology

Selective Laser Sintering (SLS)

HARDWARE

Dimensions

620 x 400 x 660 [mm] (24.4 x 15.8 x 26.0 [in])

Total weight

41.0 [kg] (90.4 [lbs])

PACKAGING

Size of package

780 x 480 x 960 [mm] (30.7 x 18.9 x 37.8 [in])

Package weight

65.0 [kg] (143.3 [lbs])

Package contains

Sinterit Lisa Printer + set of accessories + Manuals

POWER

Power supply

220-240 [V] AC, 50/60 [Hz], 7 [A]

(100-130 [V] AC, 50/60 [Hz], 15 [A])

Average power consumption

0.9 [kW]

Maximum power consumption

1.6 [kW]

Tape of laser

Class 4, IR 5 [W]; λ =808 [nm]

Beam divergence

θ = 10 [°]

Beam output

CW (continuous wave)

INDEPENDENT HEATING SYSTEM

Multi zone

Heated piston, cylinder, Feed Bed, Print Bed

Max. temperature in the chamber

190 [oC] / 374 [oF]

POWDER

Powder PA12 Smooth - polyamide 12

20-100 [μm], average size 38 [μm]

Powder Flexa Black - TPU

20-105 [μm]

Powder Flexa Grey - TPU

20-105 [μm]

Storage powder temperature

(min-max)

10-40 [oC] (50-104 [oF])

11 Sinterit Lisa USER MANUAL

PRINTER PARAMETERS

Size of Print Bed

150 x 200 x 160 [mm] (5.9 x 7.9 x 6.3 [in])

High accuracy max. print volume

Pa12 - 90 x 130 x 130 [mm] (3.5 x 5.1 x 5.1 [in])

Flexa - 110 x 150 x 150 [mm] (4.3 x 5.9 x 5.9 [in])

XY accuracy

from 0.05 [mm] (0.002 [in])

Min. layer thickness

0.075 [mm] (0.003 [in])

Min. wall thickness XZ

0.4 [mm] (0.015 [in])

The layer height Z (min-max)

0.075-0.175 [mm] (0.003-0.007 [in])

SOFTWARE

Control software/firmware

Sinterit Studio 2016

Operated file formats

STL, OBJ, 3DS, FBX, DAE, 3MF

OS compatibility

Microsoft Windows

External communication

USB, WiFi

COMMUNICATION

LCD touchscreen

Capacitive, colour - 4 [in]

On-board camera

Built-in

SAFETY

Certificates

CE (class A) according to IEC 60825-1 Ed. 3 (2014)

FCC (class A)

IEC protection class

Class I

Laser product class

Class 1, invisible laser radiation

12 Sinterit Lisa USER MANUAL

C. Contents of the Sinterit Lisa pack

● The Sinterit Lisa 3D Printer;

● A package for the additional equipment;

13 Sinterit Lisa USER MANUAL

D. Parameters - print design guide

Wall thickness

The 3D model’s wall must be thick enough to support the model.

We recommend working with 0.8 [mm] for larger objects, in smaller

objects you can have a lower wall thickness of 0.4 [mm].

Embossed and engraved details - minimum detail size

Selective Laser Sintering is one of the 3D Printing processes with

the highest accuracy; up to 0.1 [mm] is enough to create clearly

visible details. If you plan to put some embossed and engraved

DETAILS, we recommend adding the minimum thickness of 0.15

[mm] and depth of 0.15 [mm].

Embossed and engraved text

If you plan to put some TEXT embossed we recommend adding a

minimum line thickness of 0.5-0.6 [mm] and a depth of 0.5 [mm].

Use a bold sans-serif font for readability, such as Arial Bold f.ex.

Minimum feature size

The minimum feature size for printing with SLS is 1 [mm]. If your

feature is a thin wire connected on both sides, you can go slightly

thinner to 0.5 [mm], otherwise, we recommend at least 0.8 [mm]

thickness.

Functional gap - moving or interlocking parts

A powerful feature of SLS is that you can print moving parts in one

go. You should keep at least 0.2 [mm] clearance between

elements. We recommend keeping at least 0.5 [mm] if you are a

beginning user.

14 Sinterit Lisa USER MANUAL

Escape holes

Sometimes you have to increase your clearance or create extra

escape holes for the powder to get out f.ex when you have moving

parts like hinges over a long distance. We recommend making in

the model at least 4 [mm] diameter for one escape hole, 2 [mm] for

two or more.

4. Installation of the printer

To ensure safe use of the Sinterit Lisa Printer, please read and follow the instructions below.

Keep this manual for future use. Also, be sure to follow all warnings and instructions marked

on the product.

WARNING!

Only trained and qualified personnel should install, replace or service the

equipment.

The device should be installed in accordance with these instructions and by

trained personnel.

A. Environment and place of installation

● The Sinterit Lisa Printer should be placed at room temperature.

● The room must be well ventilated, adequately to its size.

● The product should be placed on a flat, stable surface that extends beyond all edges

of the product. If you place the product by the wall, the distance between the product

and the wall should be greater than 500 [mm] (20 [in]).

● The product will not work properly if it is set at an angle.

ATTENTION! Do not place or store the product:

● outdoors;

● in areas with large amounts of dust;

● in places subject to shocks, vibrations, high temperature and/or

humidity, and extreme changes in temperature and humidity;

● near water, or heat sources;

● near inflammable and volatile substances, concentrated acids or

corrosive vapours;

● in places easily accessible to children and animals.

15 Sinterit Lisa USER MANUAL

ATTENTION!

● Never use wood, equipment with wooden elements and flammable

substances while working with the printer.

● The minimum distance between the printer and wooden parts is 200

[mm].

● The printer emits large amounts of heat (60oC), and therefore it is

prohibited to place it on wood or wooden furniture.

B. Power supply:

● Use only the power cord supplied with the product.

● The printer must be connected to a grounded outlet to prevent electric shock in the

event of a fault.

● When connecting/disconnecting the plug to/from the power source always hold the

cover, not the cord.

WARNING!

Do not use cables from other devices. Using the power cables from other

devices or connecting the power cord supplied with the product to other

devices may cause fire or electric shock.

ATTENTION!

Never disassemble, modify or repair the power cord, plug, devices inside the

printer, except as described in the product manual.

● The product should be placed near a wall outlet, which can be easily unplugged.

● It is recommended to use UPS units that, in the case of a momentary power failure,

will allow the printing process to finalise.

● When an extension cord is used for the power supply of the product, make sure that

the total power consumption of all devices connected to it does not exceed the

extension cord's limit. Also make sure that the total current drawn by connected

equipment does not exceed the ampere rating for AC wall outlet.

● Power cables should be placed in such a place that they are not rubbed, cut, pulled or

twisted.

ATTENTION!

● Do not place objects on the power wires.

● Do not place power cords in path where people will have to walk

or run.

16 Sinterit Lisa USER MANUAL

● Pay special attention to the fact that the power cables are not bent at

the points of connection of the printer.

● Disconnect the plug whenever it is planned to shift/transfer the device.

In the following situations, unplug the product from the power supply and contact a qualified

service personnel:

1. the power cord or plug is damaged,

2. some liquid got into the product,

3. the product has been dropped or the case has been damaged;

4. the product does not operate properly or clear changes in efficiency have been

observed.

Do not adjust controls that are not described in the manual.

ATTENTION! Do not:

● spill liquid on the product;

● put any containers on the equipment, in particular containing water;

● handle it with wet hands;

● block or cover the vents and openings in the product;

● touch movable parts.

ATTENTION! If the device is not used for a long time (e.g. vacation), unplug

the power cord from the socket.

5. Sinterit Studio software - installation

Technical requirements to install Software:

● Windows 7 or higher,

● Minimum 500 MB of disk space,

● Minimum 2 GB of RAM,

● Graphics adapter compatible with OpenGL 3.0 or higher.

1. Connect the USB flash drive included in the set to the computer USB port.

2. Locate the Sinterit Studio folder.

3. Open SinteritStudioSetup.exe.

17 Sinterit Lisa USER MANUAL

4. Select the language for the installation.

5. Act accordingly to the messages on the installation screen.

6. After the installation, the software is ready to use.

18 Sinterit Lisa USER MANUAL

Image. Installing Sinterit Studio.

IMPORTANT!

Be sure to carefully read the license agreements and accept them.

Chapter 17.

6. Initial startup of the device after delivery

1. Take the printer out of the package. Carefully discard protective foil and paper.

2. Place it on a stable and hard surface (ideally the target location of the printer).

3. Connect the power cord.

4. Switch the power button (from “0” to “1”) located on the back.

5. Check whether the red safety button is out. If not, rotate it clockwise at a quarter of a

turn (the black flange of the button).

6. Place the key in the ignition and turn clockwise at a quarter of a turn. After a moment,

the device will start.

Image. Off/On key positions.

19 Sinterit Lisa USER MANUAL

Other manuals for LISA

4

Table of contents

Other SINTERIT 3D Printer manuals

SINTERIT

SINTERIT LISA User manual

SINTERIT

SINTERIT LISA User manual

SINTERIT

SINTERIT Lisa Pro User manual

SINTERIT

SINTERIT Lisa X Installation and operating instructions

SINTERIT

SINTERIT Lisa X User manual

SINTERIT

SINTERIT Lisa X Repair manual

SINTERIT

SINTERIT LISA User manual

SINTERIT

SINTERIT LISA User manual

SINTERIT

SINTERIT Lisa X Installation and operating instructions

SINTERIT

SINTERIT Lisa Pro User manual