PRODUCT

P 1/ 24

Optional accessories

Finish nails

Battery BL1815

Battery BL1815N

Battery BL1820

Battery BL1830

Battery BL1840

Battery BL1850

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Four port multi charger DC18SF

Automotive charger DC18SE

Standard equipment

Nose adapter ................. 1

Hex wrench 3 ................ 1

Plastic carrying case ...... 1

(for some countries only)

Models No.

Description

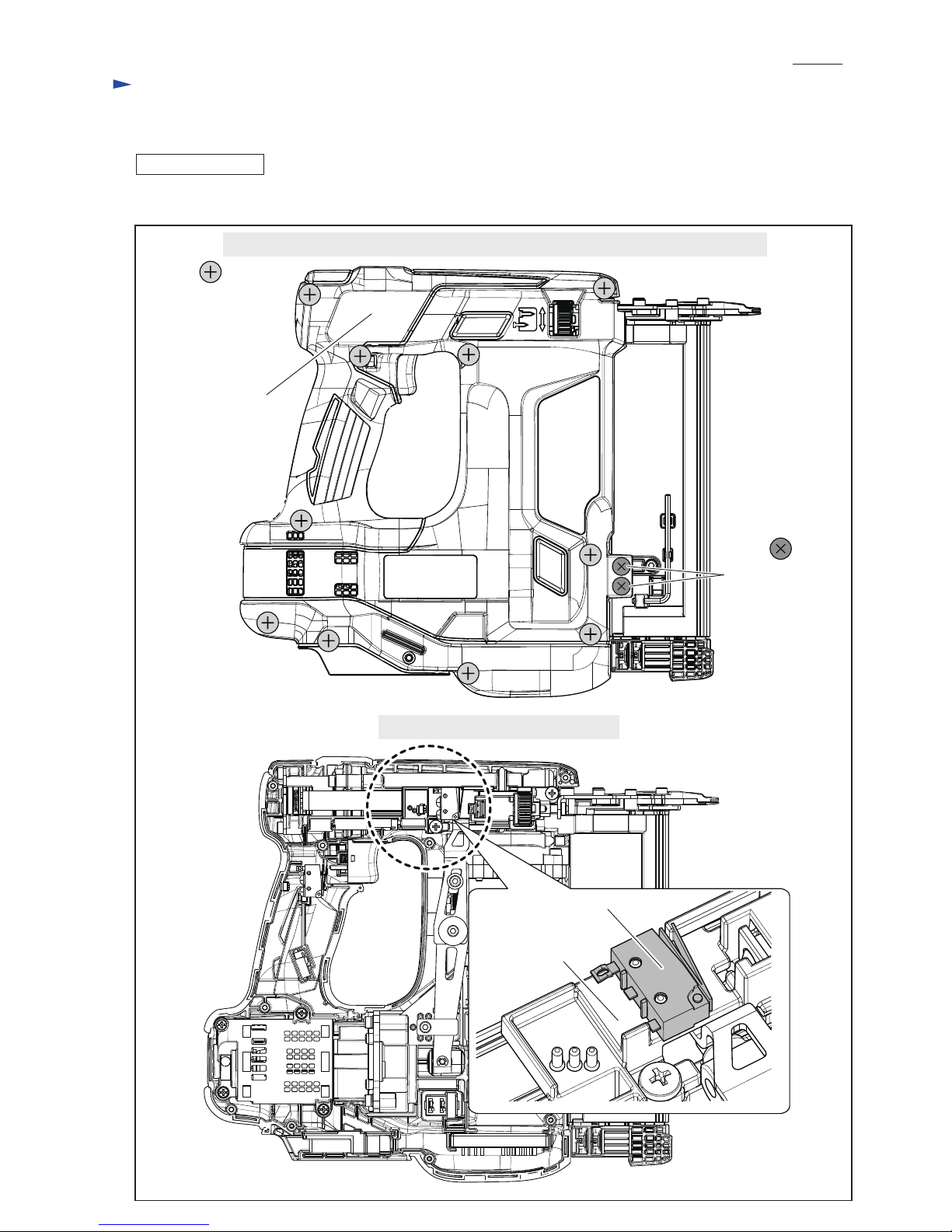

CONCEPT AND MAIN APPLICATIONS

DBN500

Cordless brad nailer 50mm (2")

DBN500 is cordless brad nailer powered by 18V Li-ion battery.

Compressed air generated by piston work with DC motor pushes down Driver to

shoot Brad nails. The mechanism provides less reaction force and “air nailer like”

shot feeling to the operator.

Other features are as follows:

• Higher durability than competitors’ models

• Easy-to-see slim nose tip

• Rocker switch to select Sequential mode / Bump fire mode

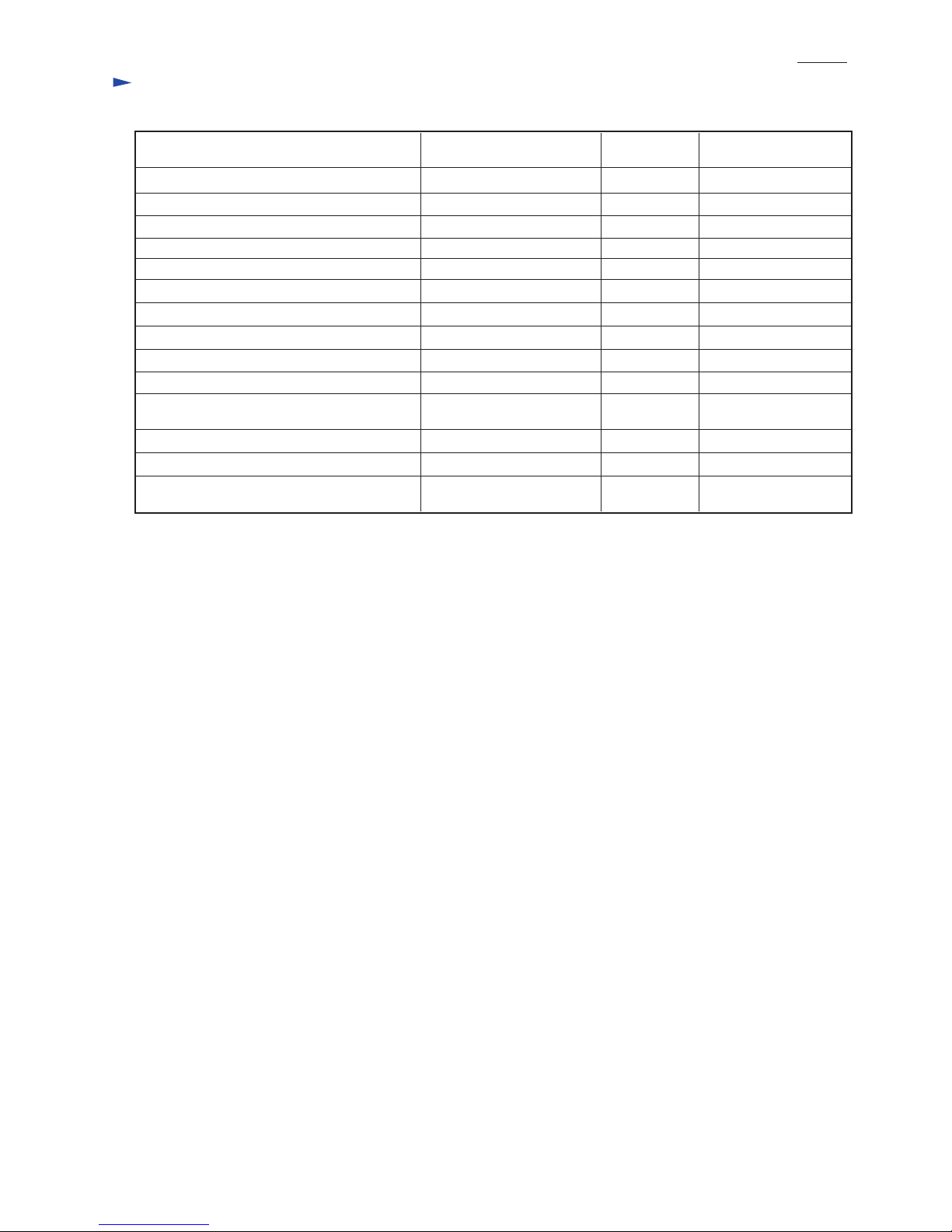

Specification

W

L

H

Length: mm (")

Type

Nail

Battery

Finish

15, 20, 25, 30, 32, 35, 38, 40, 45, 50

(5/8, 3/4, 1, 1-3/16, 1-1/4, 1-3/8, 1-1/2, 1-5/8, 1-3/4, 2)

Magazine capacity (pcs)

Shot quantity on a single full battery charge

Quick response (pcs/sec.) 2

Weight according to EPTA-Procedure 01/2003: kg (lbs) 3.3 (7.3), 3.3 (7.3), 3.5 (7.7), 3.5 (7.7), 3.5 (7.7) *6

*3 One nail is fired first by pushing Contact arm against workpiece, then by pulling Trigger with the Contact arm

kept pushed; nail cannot be fired when the steps are reversed. Another one can be fired by releasing Trigger,

then by repeating the steps; however, cannot be fired if Trigger is not released before repetition of the steps.

*4 Nail is fired first by pulling Trigger then by bumping Contact arm against workpiece with Trigger kept pulled.

As long as Trigger is kept pulled, nails can be fired one after the other continuously every time when Contact arm

is bumped against workpiece.

*5 Nail is fired first by pushing Contact arm against workpiece then by pulling Trigger with Contact arm kept pushed.

Another nail can be fired by releasing then re-pulling Trigger even if Contact arm is kept pushed;

another nail cannot be fired if Trigger is not released.

*6 2.9kg (5.5lbs) without Battery

Nail gauge 18Ga

Nails per strip 100

110

1,000*1

LED job light Yes

1.5, 2.0, 3.0, 4.0, 5.0

24, 27, 54, 72, 90

18

Li-ion

15, 24, 22, 36, 45 with DC18RC

Voltage: V

Capacity: Ah

Cell

Charging time (approx.): min.

Energy capacity: Wh

Yes

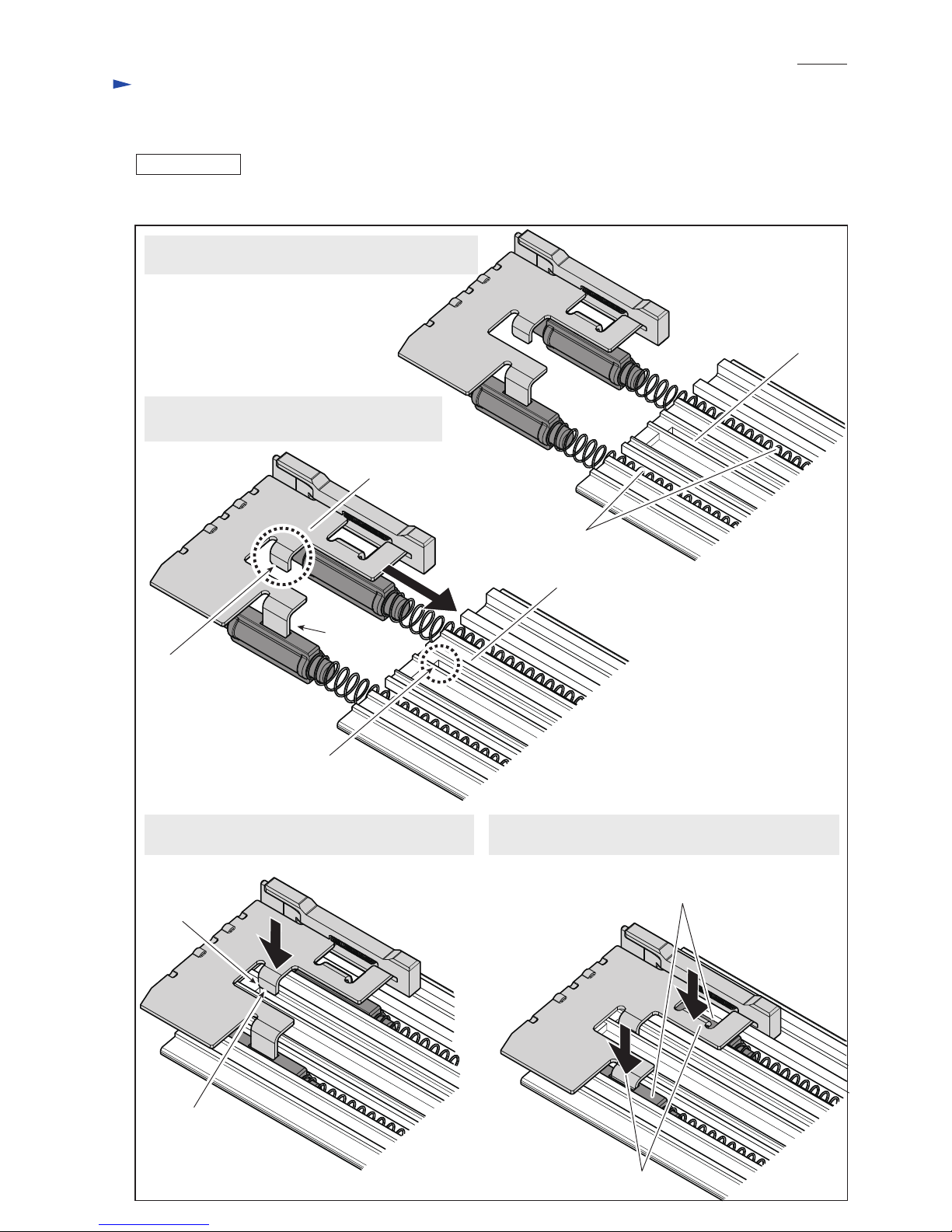

Yes (Tool-less)

Rocker switch

Driving depth adjustment

Anti-dry-fire mechanism

Change of Bump fire mode and sequential mode

2 mode pattern

Operation

mode Auto change mode between

Bump fire*4and single fire*5

Sequential*3

97 (3-13/16)*2

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 294 (11-5/8)*1

318 (12-1/2)

*1 With Battery BL1830

*2 103mm (4-16") when using Hook

Note: The standard equipment may vary by country

or model variation.

TECHNICAL INFORMATION

460Max output (W)

Battery .................. 1 or 2*8

Charger ................. 1*8

Battery cover......... 1*9

Safety goggles ...... 1

*8 Battery and charger are not supplied with “Z” model

*9 Supplied with the same quantity of extra Battery

OFFICIAL USE

for ASC & Sales Shop