3LTAGE WARNING: Beforeconnectingthetooltoa powersource (receptacle,

Itlet, etc.) be sure the voltage supplied is the same as that specified on the

meplateof thetool. A power source

with

voltage greater than that specified

)r the toolcan result

in

SERIOUS INJURY tothe user

-

as well as damageto

le tool. If

in

doubt, DO NOT PLUG INTHE TOOL. Using a power source

with

oltage less than the nameplate rating is harmful to the motor.

;ROUNDING INSTRUCTIONS

\LL GROUNDED, CORD-CONNECTED

TOOLS:

In

the event of a malfunctionor

Breakdown, giounding provides a pathof least resistance for electric current to

educe the risk of electric shock. This toolisequippedwithan electric cordhaving

an

equipment-grounding conductor and a grounding plug. The

plug

must be

ilugged into a matching outlet that is properly installed and grounded

in

ac-

zordance with all local codes and ordinances.

Do

not modify the

plug

provided-if

it

will

not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connectionof the equipment-grounding conductor can result

in

a risk

of electric shock. The conductor

with

insulation having an outer surface that

is

green withor without yellow stripes is the equipment-groundingconductor.

If

repair or replacementof

the

electriccordor plugisnecessary, donotconnect

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions

are notcompletely understood, or if

in

doubt as to whether thetoolis properly

grounded.

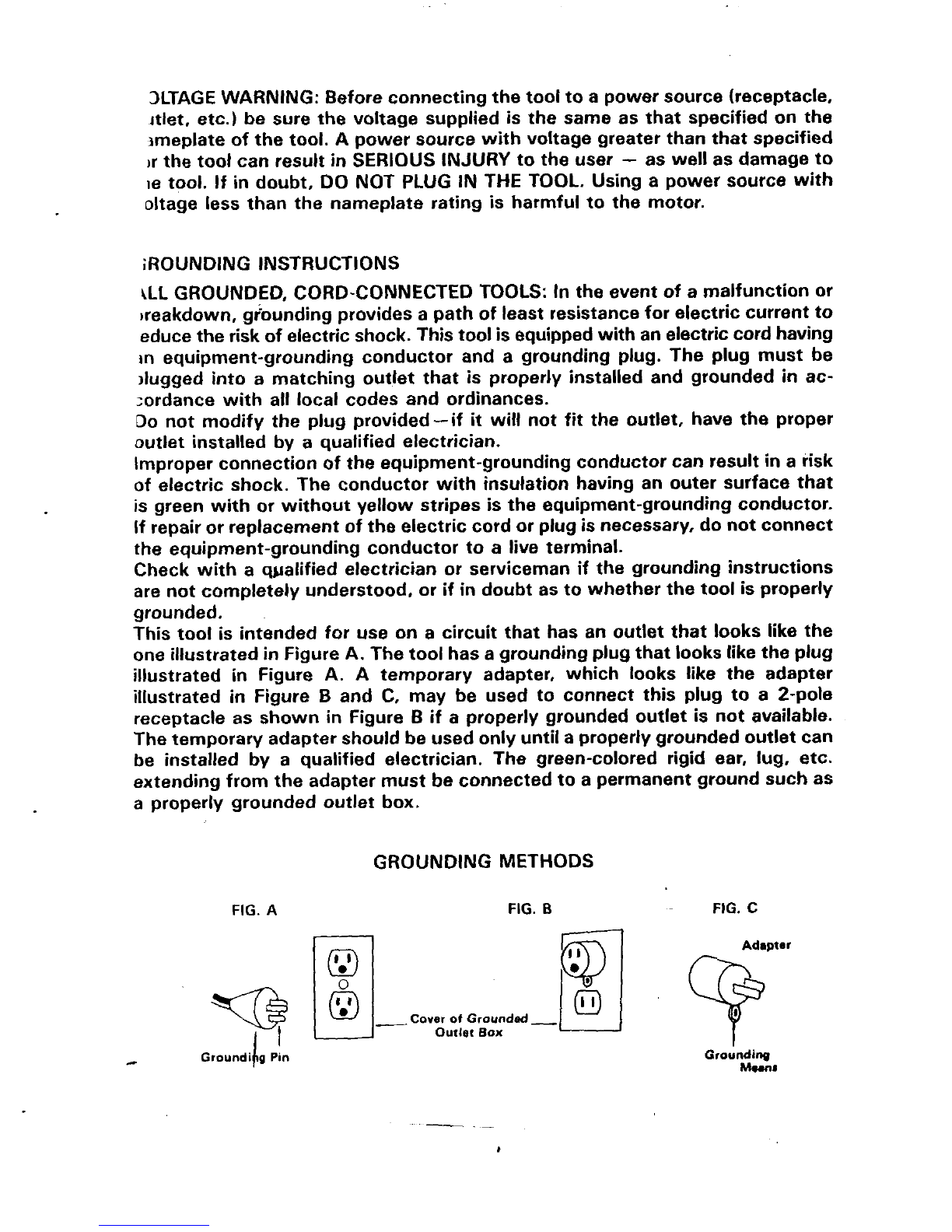

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated

in

FigureA. Thetoolhasa grounding

plug

thatlooks likethe

plug

illustrated

in

Figure A.

A

temporary adapter, which looks like the adapter

illustrated

in

Figure B and C, may be used

to

connect this

plug

to a 2-pole

receptacle as shown

in

Figure

B

if a properly grounded outlet is not available.

Thetemporary adapter should be usedonly

until

aproperly groundedoutlet can

be installed by a qualified electrician. The green-colored rigid ear,

lug,

etc.

extending from the adapter must beconnectedtoa permanentground such as

a properly grounded outlet box.

GROUNDING METHODS

FIG.

A

FIG.

B

~

FIG.

C

Groundibg

Pin

--

I

Grounding

Munl