Makita AN901 User manual

Other Makita Power Tools manuals

Makita

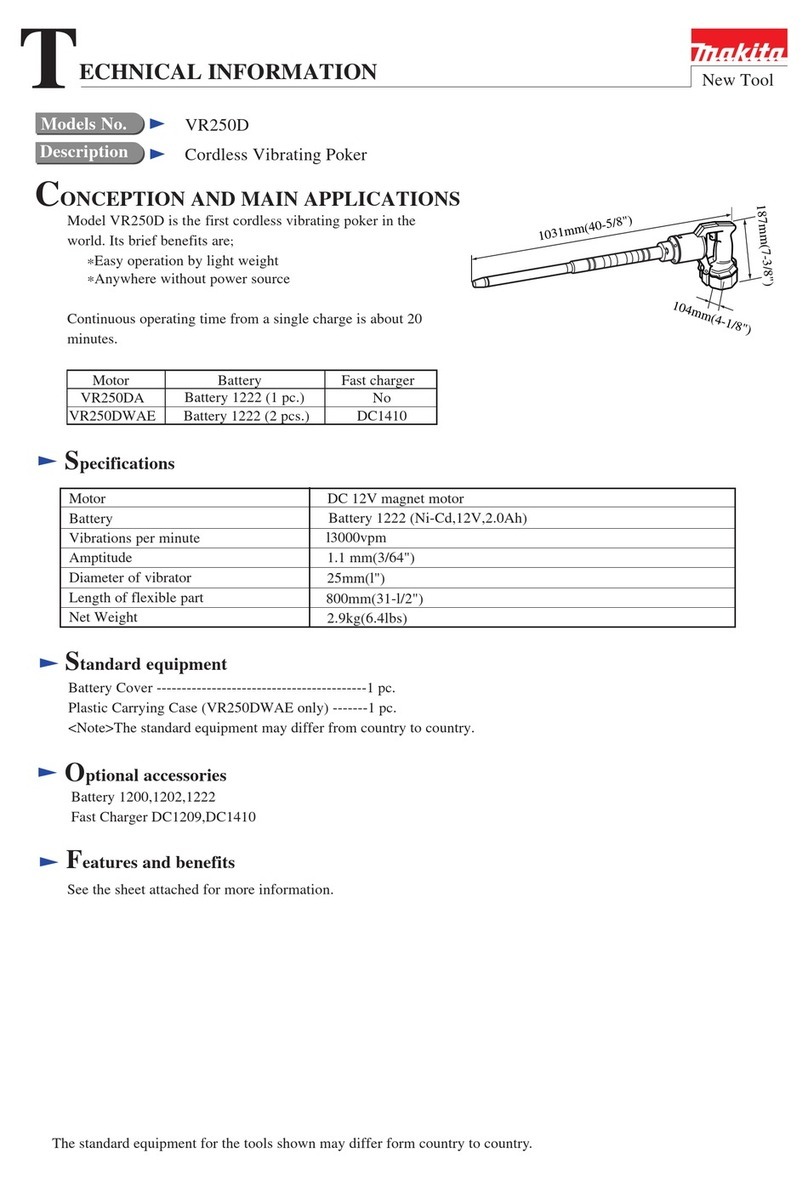

Makita VR250D Manual

Makita

Makita HM1801 User manual

Makita

Makita HM0810T User manual

Makita

Makita DTW251RMJ User manual

Makita

Makita DSC163ZK User manual

Makita

Makita BSS730 User manual

Makita

Makita HR007G User manual

Makita

Makita ST113D User manual

Makita

Makita AT638 User manual

Makita

Makita DTW180RFE User manual

Makita

Makita WR100D User manual

Makita

Makita STRAIGHT SHEAR JS1660 User manual

Makita

Makita DTW181 User manual

Makita

Makita HG6530V User manual

Makita

Makita AN902 User manual

Makita

Makita 6704D User manual

Makita

Makita 3612 User manual

Makita

Makita BSS500 User manual

Makita

Makita DTW250 User manual

Makita

Makita XWT04Z User manual