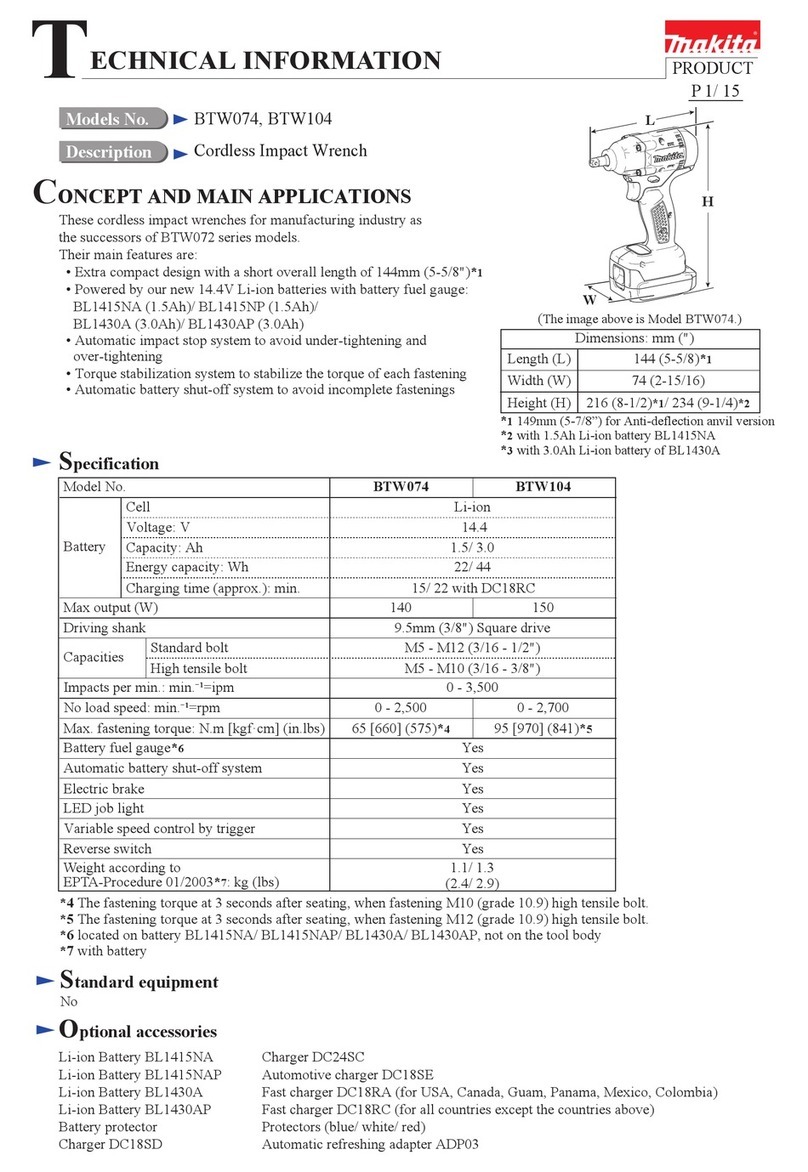

Models No.

PRODUCT

P 1/ 16

Model BHS630 is a 165mm (6-1/2") Cordless Circular Saw powered by

18V/3.0Ah Li-ion battery Model BL1830.

Its main features are:

•Able to cut up to 66mm (2-5/8") thick wood with a single stroke,

which no competitors’ 18V models can do.

• In spite of compact and lightweight design, performs the same smooth

and comfortable cutting as AC circular saws.

• Compatible with 18V Li-ion battery of BL1830 equipped with the battery

protection circuit designed to protect the battery from damages due to

overdischarge, high temperature or overload current.

• High maneuverability provided by Good tool balance, Twin LED light,

Blower function and Fine parallel adjustment of base plate.

Dimensions: mm (")

Width (W)

Height (H)

Length (L) 346 (13-5/8)

220 (8-5/8)

247 (9-3/4)

Note: The standard equipment may vary by courntry or model variation.

BHS630

165mm (6-1/2") Cordless Circular Saw

TCT Saw blade 165mm (6-1/2") .................................. 1

Hex wrench 5 ................................................................ 1

Rip fence ....................................................................... 1

Dust nozzle (for European countries only) ................... 1

Battery

Blade size: mm (")

Electric brake

Max cutting capacities:

mm (")

Diameter

Hole diameter

at 45°

No load speed: min-1=rpm

Cell

Voltage:V

Capacity:Ah

Li-ion

18

3.0

Weight according to

EPTA-Procedure 01/2003*2: kg (lbs)

*Includes TCT Saw Blade, Battery BL1830 and Dust nozzle

3.5 (7.7)

Yes

Job light Yes (Twin LED light)

North America: 15.88 (5/8)

All countries except North America: 20

46 (1-13/16)

at 0° 66 (2-5/8)

3,100

165 (6-1/2)

Max output (W) 730

This model is available in the following variations.

Note: 1.3Ah Li-ion battery of BL1815 cannot be used for this model.

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

L

H

W

All models also include the accessories listed below in "Standard equipment".

Model No. Type Quantity Charger Plastic

carrying case

Battery

cover

Battery

BL1830

---

DC18RC Yes

BHS630Z

2 1

--- ---

Housing

color

Makita-blue

Makita-blue--- ---

BHS630RFE

Battery BL1830

165mm (6-1/2") TCT Saw Blades

Dust nozzle

Rip fences

Fast charger DC18RC

Charger DC18SD

Charger DC24SC

Automotive charger DC18SE

Safety goggles

Guide rail adapter

Various parts of guide rail

Charging time (approx.):

min.

15/ 22

with DC18RC

Description

OFFICIAL USE

for ASC & Sales Shop