P 2 /14

[1] NECESSARY REPAIRING TOOLS

CAUTION: Remove the battery, SAW BLADE from the machine for safety

before repair/ maintenance !

Repair

1R027

1R028

1R031

1R032

1R037

1R356 Bearing plate 10mm (for arbor press)

Bearing setting pipe 18-10.2

Bearing setting pipe 20-12.2

Bearing setting pipe 28-20.2

Bearing setting plate 8.2

Bearing setting plate 20.2

Bearing extractor (2 pcs)

Bearing extractor

1R263

1R269

1R278 Round bar for arbor 4-50

1R281 Round bar for arbor 7-50

Retaining ring S and R pliers Removing/installing Retaining ring

Removing/installing Bearing retainer 14-23

Removing Ball bearing 604ZZ

adjustment for accuracy of 90 degree/45 degree cut

Removing Ball bearing 604ZZ and 696ZZ

Removing Ball bearing 604ZZ

Supporting Gear shaft when assembling Helical gear 35,

Ball bearing 6900ZZ and Helical gear 15 to Gear shaft

Supporting Bearing box section when removing Helical gear 23,

Sleeve 10, and Ball bearing 6900ZZ from Spindle

Removing Bearing box section

Assembling Helical gear 35 to Gear shaft

Assembling Ball bearing 6900ZZ and Helical gear 15 to Gear shaft

1R003

Retaining Ring S Pliers ST-2N

Removing Retaining ring WR-26

Removing Retaining ring WR-26

Removing Helical gear 35, Ball bearing 6900ZZ and Helical gear 15

from Gear shaft

Removing Helical gear 15 and Ball bearing 6900ZZ

1R291

Wrench for bearing retainer1R316

1R212 Tip for Retaining ring pliers

90 degree set square1R208

Code No. Description Use for

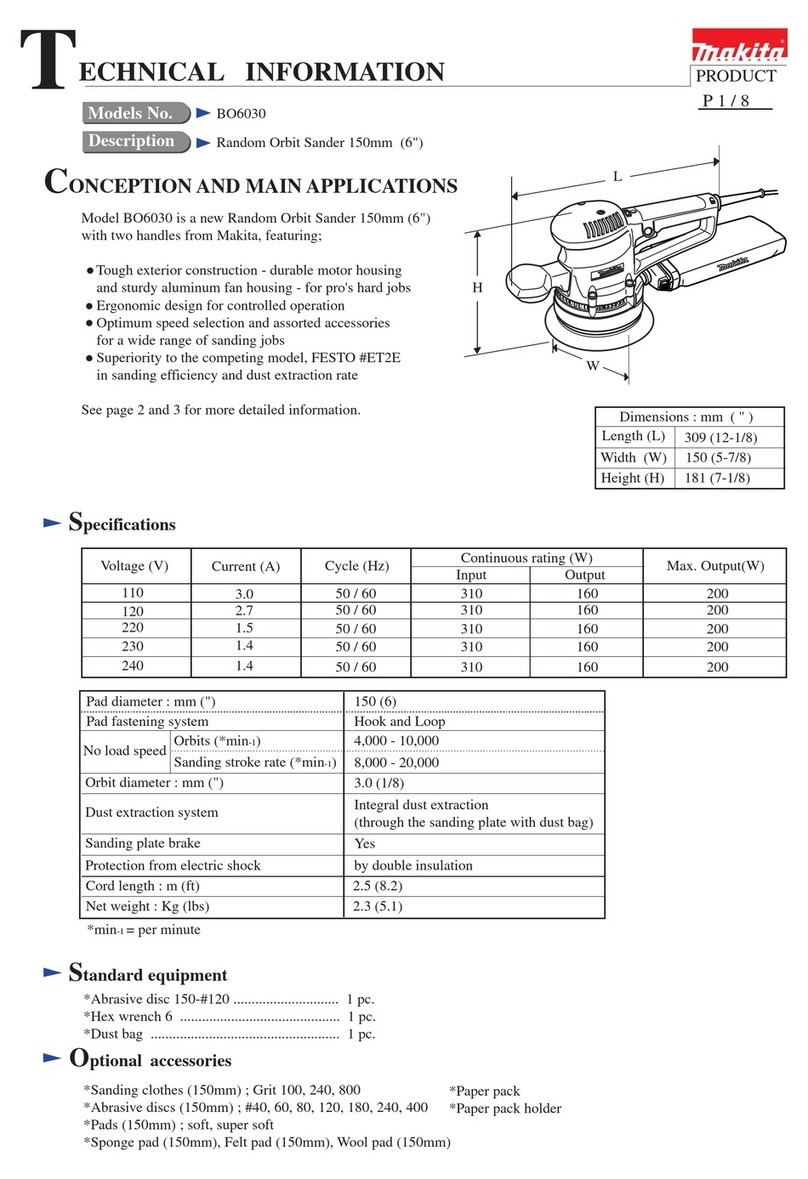

[2] LUBRICATION

Apply the following grease to protect parts and product from unusual abrasion:

Makita grease N. No.2 to the following portions designated with the black triangle

Machine oil to the following portions designated with the gray triangle

Fig. 1

(viewed from the opposite side)

19

Handle R

Thickness ring

3g to the gear room for Helical gear 23 and Helical gear 15

Surface that contacts Safety cover complete

3g to the gear room located on the opposite side for Helical gear 35

and Pinion gear of Armature shaft

51

Helical gear 23

19

Item No.

Description Portion to lubricate Lubricant

19

51

Safety cover complete

Helical gear 35

Helical gear 15