22. Have your tool repaired by an expert

This electric appliance is in accordance with the

relevant safety rules. Repairing of electric appli-

ances may be carried out only by experts other-

wise it may cause considerable danger for the

user.

ADDITIONAL SAFETY RULES ENB011-2

1. Hold the tool firmly.

2. Secure the workpiece firmly.

3. Keep hands away from moving parts.

4. Edges and chips of the workpiece are sharp.

Wear gloves. It is also recommended that you

put on thickly bottomed shoes to prevent

injury.

5. Do not put the tool on the chips of the work-

piece. Otherwise it can cause damage and

trouble on the tool.

6. Do not leave the tool running. Operate the tool

only when hand-held.

7. Always be sure you have a firm footing. Be

sure no one is below when using the tool in

high locations.

8. Do not touch the blade or the workpiece imme-

diately after operation; they may be extremely

hot and could burn your skin.

9. Avoid cutting electrical wires. It can cause

serious accident by electric shock.

SAVE THESE INSTRUCTIONS.

OPERATING INSTRUCTIONS

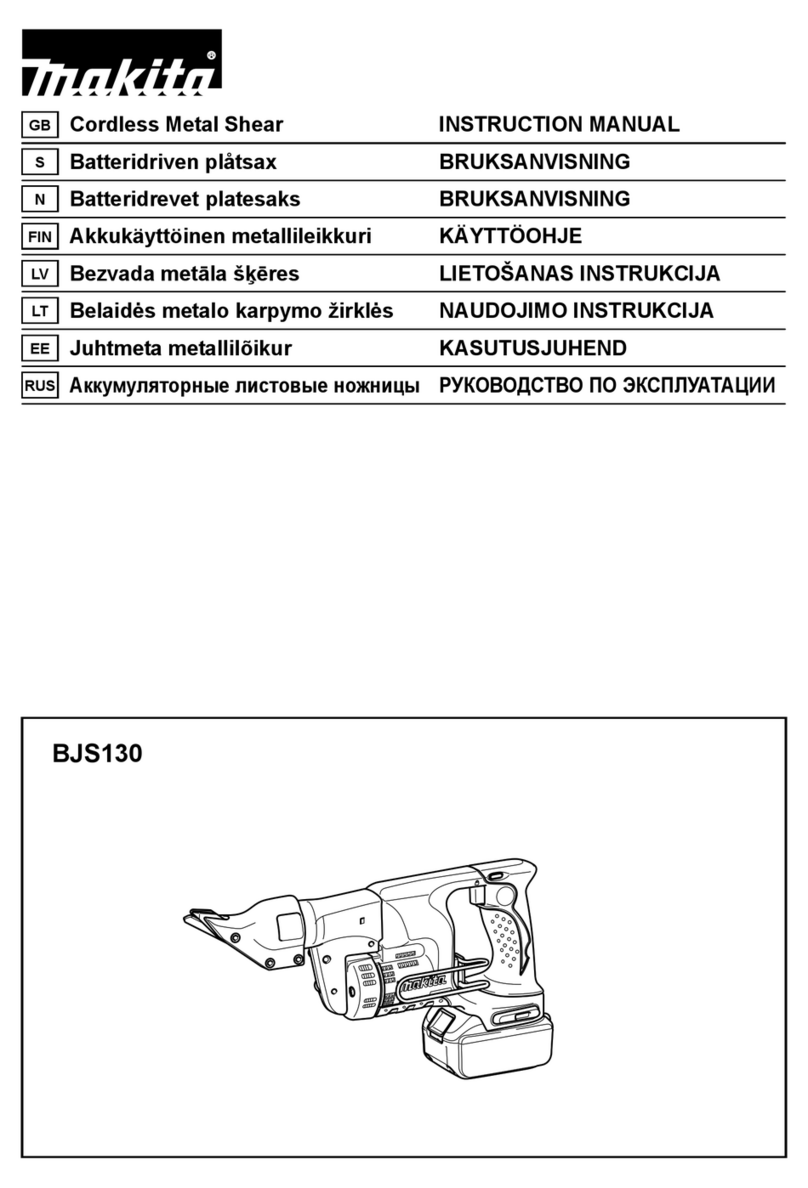

Switch action (Fig. 1)

CAUTION:

Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

‘‘OFF’’ position when released.

To start the tool, simply pull the trigger. Tool speed is

increased by increasing pressure on the trigger.

Release the trigger to stop. For continuous operation,

pull the trigger and then push in the lock button. To

stop the tool from the locked position, pull the trigger

fully, then release it.

Hook (Fig.2&3)

The hook is convenient for temporary hanging the

tool. When using the hook, pull it out in ‘‘A’’ direction

and then push it in ‘‘B’’ direction to secure in place.

When not using the hook, return it back to its initial

position by following the above procedures in reverse.

Replacement of blades

CAUTION:

•Always be sure that the tool is switched off and

unplugged before replacement of the blades.

•Never remove the blades with bare hands. Wear

gloves. Otherwise it can cause injury.

Removing cutting head (Fig. 4)

Use the hex wrench to loosen the three screws which

secure the cutting head. Pull the cutting head straight

out to remove it with turning it left and right alternately.

Removing shear blades (Fig. 5)

Remove the three screws which hold the cutting

head. When removing the second screw, be careful

not to fall the sleeve. Then the blades can be removed

easily. When removing the blades, hold the blades

and the sleeve so that they do not fall from the cutting

head.

Installing shear blades (Fig. 6)

Install the sleeve and tighten the three screws after

inserting the center blade, side blade L & R into the

cutting head. In this process, the screw heads should

be protruding 2–3mmfrom the cutting head surface.

If you will tighten the screws excessively, the cutting

head cannot be installed to the tool.

Installing cutting head (Fig. 7)

CAUTION:

Secure the cutting head firmly. Otherwise it can rotate

during operation and can cause serious injury.

Insert the cutting head into the tool with turning it left

and right alternately. Then tighten the three screws

with the hex wrench.

Operation (Fig. 8)

CAUTION:

Edges and chips of the workpiece are sharp. Wear

gloves. Otherwise it can cause injury.

Secure the workpiece firmly. Move the tool forward

keeping the side blades flush with the workpiece

surface.

Adjusting shear blade (Fig. 9)

Adjust the side blade L so that the curl of waste

material does not contact the cutting head or the

workpiece. Use the hex wrench to loosen the three

screws which hold the cutting head. Move the side

blade L back and forth to adjust it. Then tighten the

three screws with the hex wrench.

MAINTENANCE

CAUTION:

Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Lubrication (Fig. 10)

Before operation, lubricate the contact point of the

center blade and the side blades R/L. And, also

lubricate the point of the center blade near the cutting

head. To keep good cutting performance, use lubri-

cant from time to time during operation.

To maintain product safety and reliability, repairs,

maintenance or adjustment should be carried out by a

Makita Authorized Service Center.

JS1300 (E) (’100. 7. 19)

5