5ENGLISH

Battery tool use and care

1. Recharge only with the charger specied by

the manufacturer. A charger that is suitable for

onetypeofbatterypackmaycreateariskofre

when used with another battery pack.

2. Use power tools only with specically desig-

nated battery packs. Use of any other battery

packsmaycreateariskofinjuryandre.

3. When battery pack is not in use, keep it away

from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal

objects, that can make a connection from one

terminal to another. Shorting the battery termi-

nalstogethermaycauseburnsorare.

4.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact acci-

dentally occurs, ush with water. If liquid con-

tacts eyes, additionally seek medical help. Liquid

ejectedfromthebatterymaycauseirritationorburns.

5. Do not use a battery pack or tool that is dam-

aged or modied.Damagedormodiedbatteries

may exhibit unpredictable behaviour resulting in

re,explosionorriskofinjury.

6. Do not expose a battery pack or tool to re or

excessive temperature.Exposuretoreortem-

perature above 130 °C may cause explosion.

7. Follow all charging instructions and do not

charge the battery pack or tool outside the

temperature range specied in the instruc-

tions. Charging improperly or at temperatures

outsidethespeciedrangemaydamagethe

batteryandincreasetheriskofre.

Service

1. Have your power tool serviced by a qualied

repair person using only identical replacement

parts. This will ensure that the safety of the power

tool is maintained.

2. Never service damaged battery packs. Service

of battery packs should only be performed by the

manufacturer or authorized service providers.

3. Follow instruction for lubricating and chang-

ing accessories.

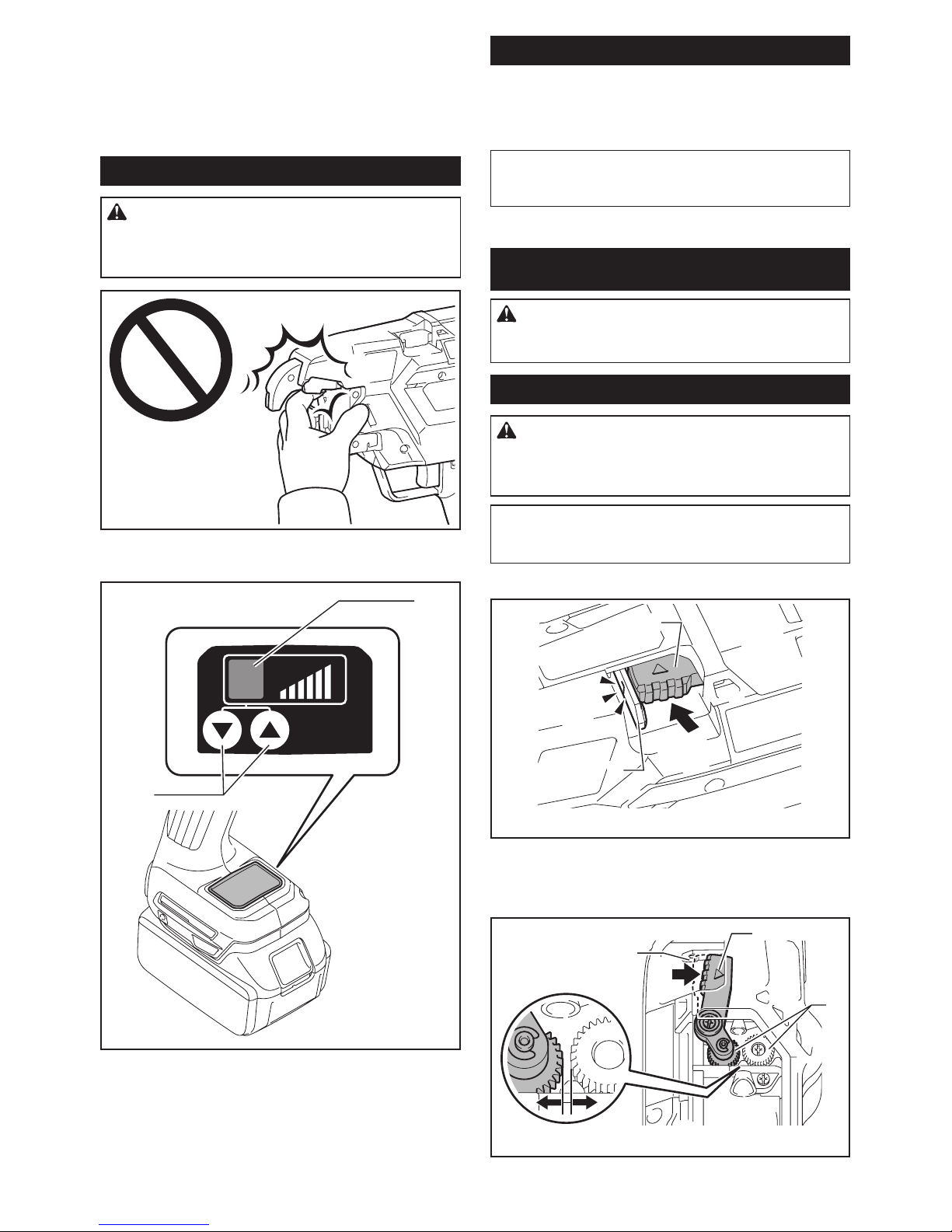

Cordless rebar tying tool safety

warnings

1.

Never point the tool toward a person. Never put

your hands or feet close to the tool tip. If you

accidentally operate the tool while it is touching

someone, it will lead to an unexpected accident.

2. Do not load wire while the power to the tool is

turned on. Otherwise, you may get caught in the

wireandinjured.

3. Do not use the tool without closing the reel

cover. Otherwise, the wire reel may come off and

cause an accident.

4. Be sure to check that the diameters of rebars

to be tied are within the tool capacity before

beginning work.

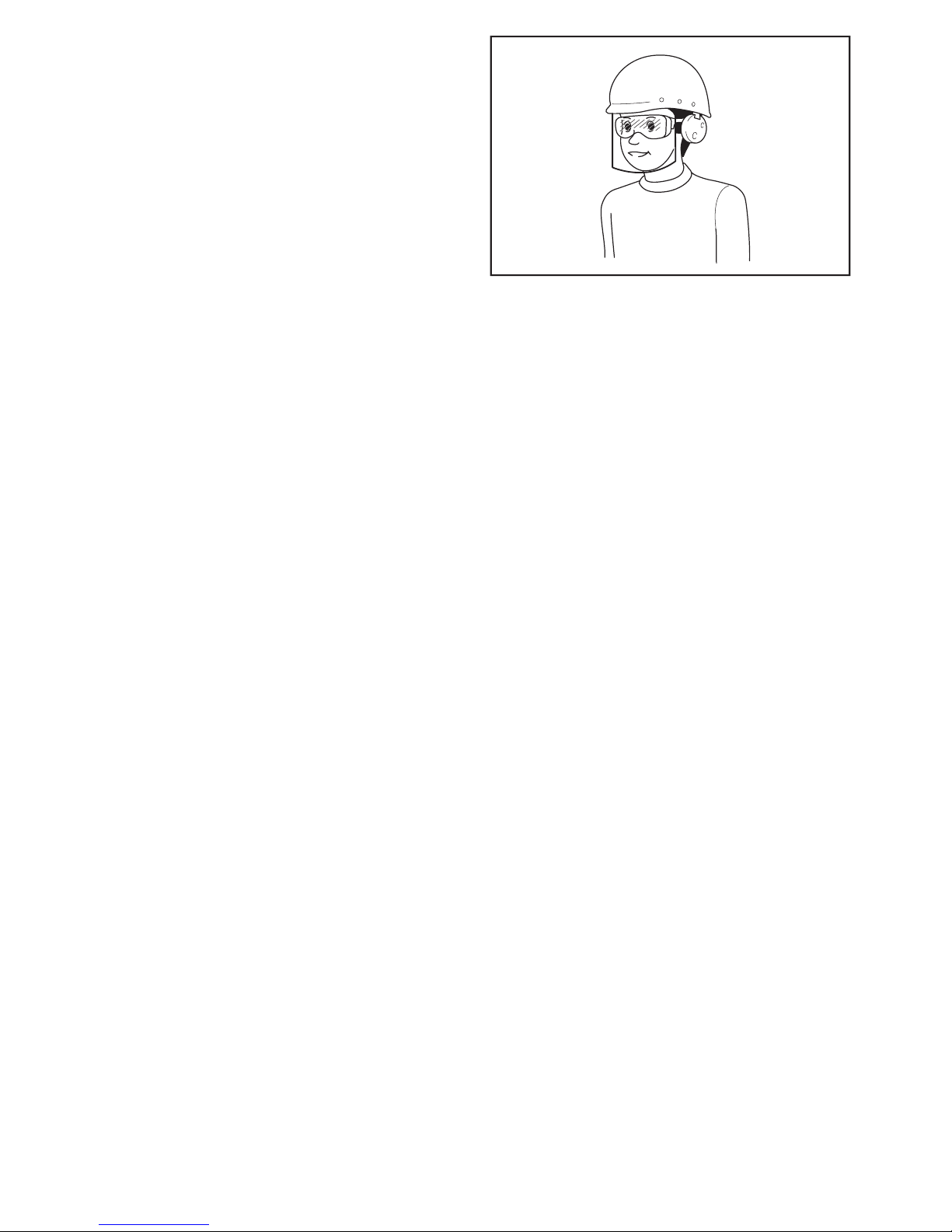

5. Wear clothes that have close-tting hemlines

and sleeves. Do not work with a towel or other

object wrapped around your neck. Otherwise,

they may get caught in the rotating part and cause

an accident.

6. Be sure to inspect the following points before

using the tool.

• Check that no parts are damaged

• Check that no bolts are loose

• Check that safety devices operate

normally

7. If any abnormalities are found, stop using the

tool immediately. Do not repair the tool by

yourself. Ask your local Makita Service Center

for repairs. If the tool is used in an incomplete

state, an accident may occur.

8. When installing the battery cartridge, be sure

to lock the trigger and do not place your nger

on the trigger. Incorrect operation may cause an

accident.

9. When tying rebars, exercise care not to move

them. If rebars move due to tying, you may be

injured.

10. Do not touch the wires during the wire tying

process. Otherwise, you may get caught in the

wireandinjured.

11. Do not bring your hands close to the tying

point during the wire tying process. Otherwise,

youmaygetcaughtinthewireandinjured.

12. Hold the grip of the tool rmly during the wire

tying process. Otherwise, your wrist may be

twisted or your body may be pulled, which may

resultinaninjury.

13. Do not move to the next tying point until the

current wire tying process is completed.

Otherwise,youmaybeinjured.

14. Pay attention to the end of the wire during the

wire tying process. Otherwise, your hand may

be caught by the end of the wire, and you may be

injured.

15. Do not touch the contact plate during the wire

tying process. If you need to touch the contact

plate, be sure to lock the trigger, or turn the

power switch off and remove the battery car-

tridge.Otherwise,youmaybeinjured.

16. When you have completed the wire tying pro-

cess, pull the tool up vertically. Otherwise, the

arm may be caught on rebars, which may cause

an accident.

17. Be careful not to drop, bump, or hit the tool.

If a strong impact is applied prior to the tool

being used, make sure that the tool is not dam-

aged or cracked, and that the safety devices

operate normally. Otherwise, an accident may

occur.

18. If any of the following phenomena occur, lock

the trigger, turn the power switch off, and

remove the battery cartridge from the tool.

If the tool operates incorrectly, an accident may

occur.

• If an operating sound is heard as soon as

the battery cartridge is mounted.

• If overheating or abnormal smells or

noises are detected.

• When you are taking measures in

response to the error display. (Ask your

local Makita Service Center for repairs.)

• When loading or unloading a wire reel.