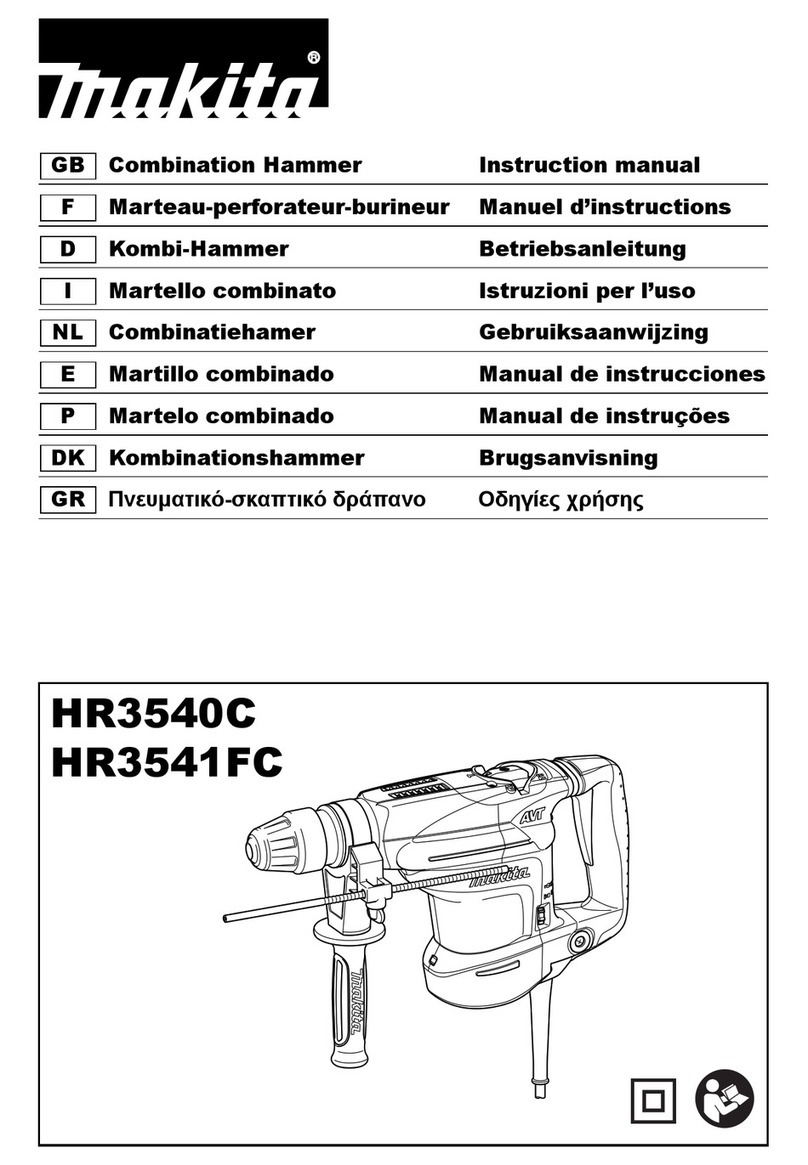

Makita DTR181 User manual

Other Makita Tools manuals

Makita

Makita HR2631F User manual

Makita

Makita DTM41 User manual

Makita

Makita M8600 User manual

Makita

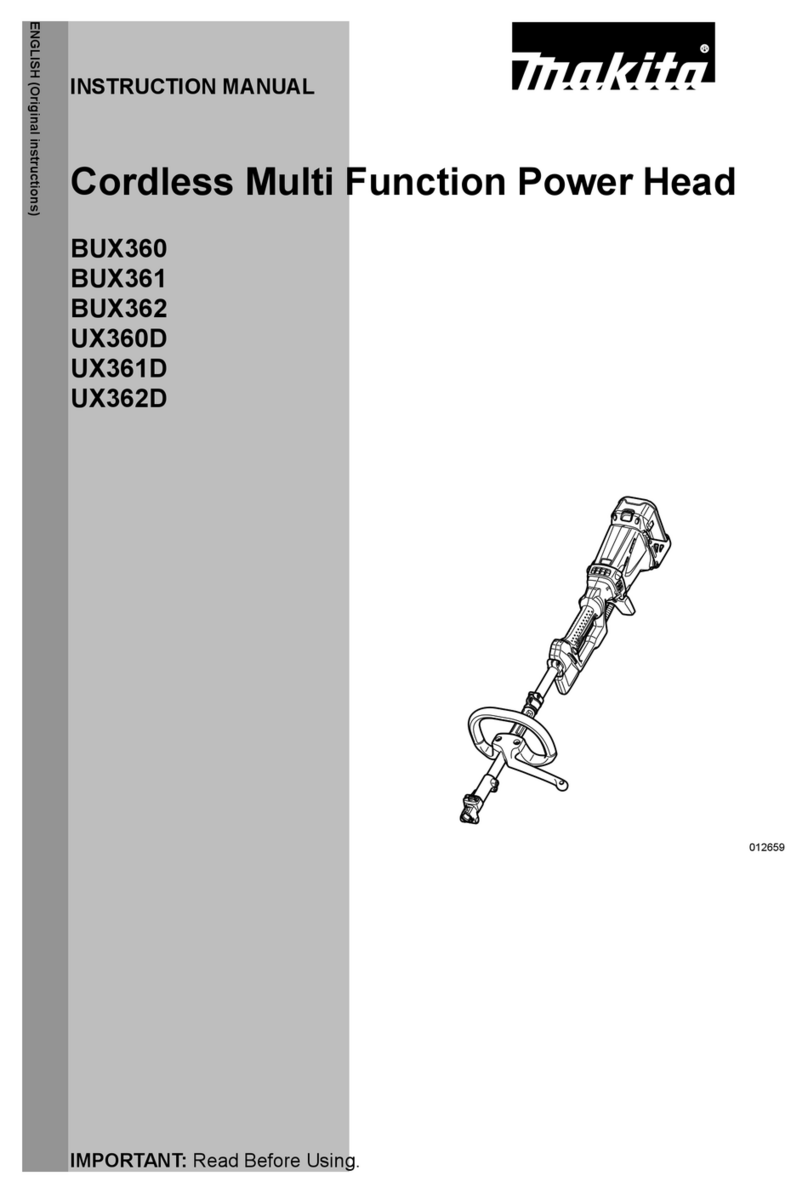

Makita BUX360 User manual

Makita

Makita M1902 User manual

Makita

Makita HR2300 User manual

Makita

Makita HR2631FT User manual

Makita

Makita DCO181 User manual

Makita

Makita DTM52 User manual

Makita

Makita HR007G User manual

Makita

Makita DGP180 User manual

Makita

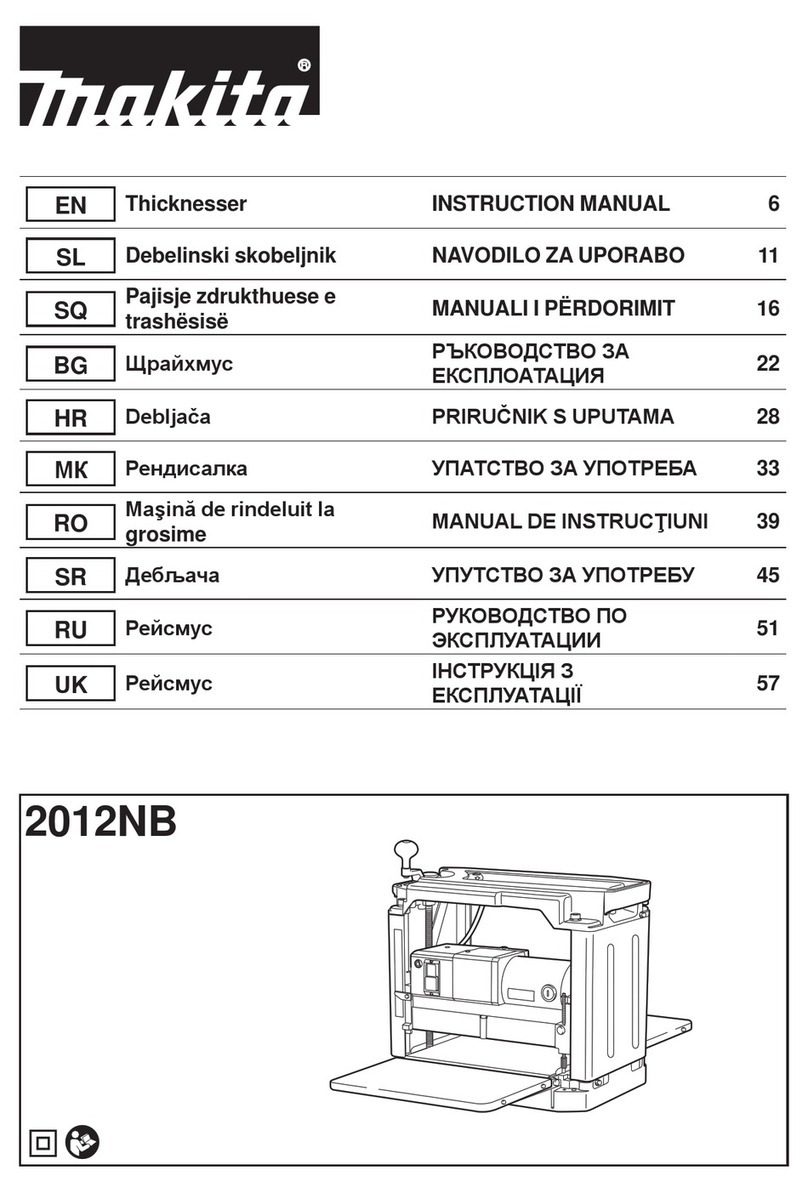

Makita 2012NB User manual

Makita

Makita HR2652 User manual

Makita

Makita DTS131 User manual

Makita

Makita KJ150 User manual

Makita

Makita HM1200 User manual

Makita

Makita HR2652 User manual

Makita

Makita MW001G User manual

Makita

Makita BV4500-118 User manual

Makita

Makita BHR242 User manual