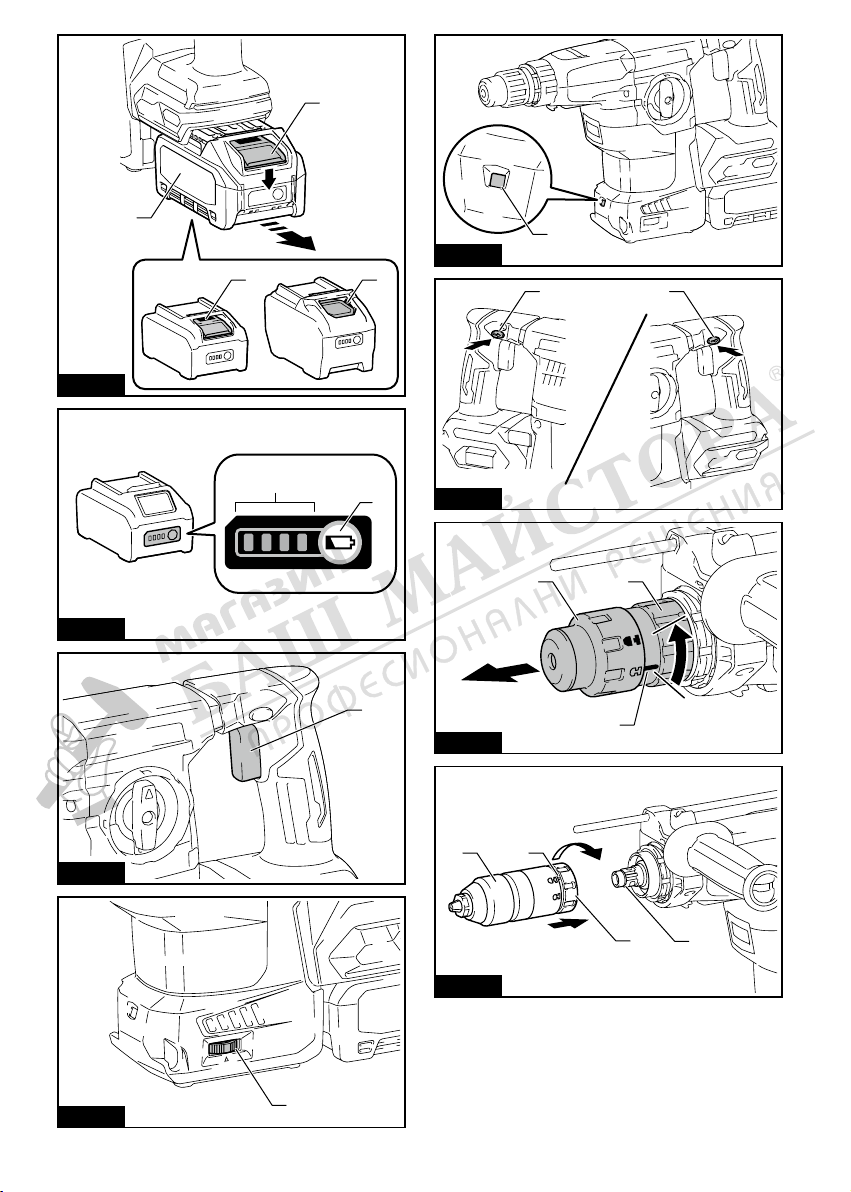

Makita HR008G User manual

Other Makita Tools manuals

Makita

Makita BV17-177 User manual

Makita

Makita UX01G User manual

Makita

Makita DCO181 User manual

Makita

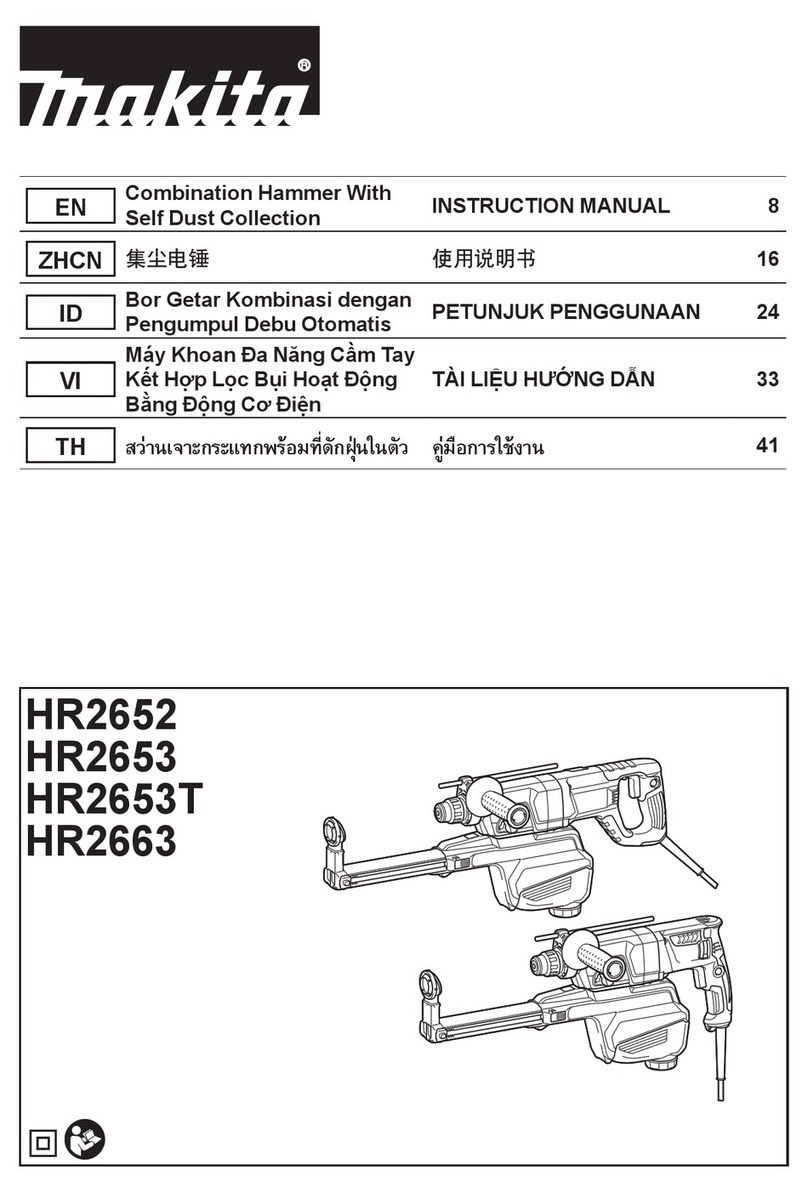

Makita HR2652 User manual

Makita

Makita HR2652 User manual

Makita

Makita DHR202 User manual

Makita

Makita M3601 User manual

Makita

Makita BHR261 User manual

Makita

Makita DTM52 User manual

Makita

Makita HR2300 User manual

Makita

Makita M8600 User manual

Makita

Makita HR001GM201 User manual

Makita

Makita BHR261T User manual

Makita

Makita HR3011FC User manual

Makita

Makita DDG460 User manual

Makita

Makita HM1317C User manual

Makita

Makita JS8000 User manual

Makita

Makita AS001G User manual

Makita

Makita HR3541FCX User manual

Makita

Makita HR2300 User manual