Manitou STACKY 10 FR S16 User manual

647263 EN (06/12/2012)

STACKY

STACKY 10 FR S16 - STACKY 10 FR D28

STACKY 10 LE S16 - STACKY 10 LE D28

STACKY 14

MANITOU BF

BP 10249

44158 ANCENIS CEDEX - FRANCE

TEL: 33 (0)2 40 09 10 11

YOUR DEALER

OPERATOR'S MANUAL

(ORIGINAL MANUAL)

THIS OPERATOR'S MANUAL MUST BE KEPT IN THE STACKER AND MUST BE READ AND UNDERSTOOD BY OPERATORS.

STACKY 10 FR D28

STACKY 10 LE S16

STACKY 14

1 - OPERATING AND SAFETY INSTRUCTIONS

2 - DESCRIPTION

3 - MAINTENANCE

4 - TOOLS

THE TEXT AND ILLUSTRATIONS IN THIS DOCUMENT MUST NOT BE REPRODUCED EITHER WHOLLY OR IN PART.

06/12/2012

1st edition

1

OPERATING

AND SAFETY INSTRUCTIONS

1-2 STACKY operating and safety instructions 2012.12

1-3

STACKY operating and safety instructions2012.12

TABLE OF CONTENTS

INSTRUCTIONS TO THE COMPANY MANAGER 1-5

THE SITE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

THE OPERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

THE STACKER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

A - FITNESS OF THE STACKER FOR PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

B - STACKER MODIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

THE INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

THE MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

INSTRUCTIONS FOR THE OPERATOR 1-7

PREAMBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

GENERAL INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

A - OPERATOR'S MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

B - AUTHORISATION FOR USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

C - MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

D - MODIFICATION OF STACKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

E - LIFTING PEOPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

F - STACKER DIRECTION OF TRAVEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

UNLADEN AND LADEN STACKER OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . 1-8

A - PRIOR TO USING THE STACKER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

B - DRIVER'S OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

C - ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

D - VISIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

E - SWITCHING ON THE STACKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

F - STACKER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

G - STOPPING THE STACKER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

H - CHARGING THE BATTERY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

INSTRUCTIONS FOR HANDLING A LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

A - CHOICE OF TOOL (EXCEPT STACKY 14). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

B - WEIGHT AND CENTRE OF GRAVITY OF THE LOAD . . . . . . . . . . . . . . . . . . . . . . .1-12

C - PICKING UP A LOAD ON THE GROUND. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

D - PICKING UP AND SETTING DOWN A LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

E - SETTING-DOWN A LOAD IN A STORAGE STRUCTURE. . . . . . . . . . . . . . . . . . . . .1-13

F - PICKING UP A LOAD IN A STORAGE STRUCTURE. . . . . . . . . . . . . . . . . . . . . . . .1-14

G - PICKING UP AND SETTING DOWN A SUSPENDED LOAD (EXCEPT STACKY 14) . . . . .1-14

H - TRAVELLING WITH A SUSPENDED LOAD (EXCEPT STACKY 14) . . . . . . . . . . . . . . .1-15

STACKER MAINTENANCE INSTRUCTIONS 1-16

GENERAL INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

HYDRAULIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

ELECTRICITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

STACKER DECOMMISSIONING AND DISPOSAL 1-17

DECOMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

DISPOSAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

1-4 STACKY operating and safety instructions 2012.12

MEANING OF THIS SYMBOL:

WARNING! BE CAREFUL !

YOUR SAFETY OR THAT OF OTHERS IS AT RISK

RISK OF DAMAGE TO THE STACKER

1-5

STACKY operating and safety instructions2012.12

INSTRUCTIONS TO THE COMPANY MANAGER

THE SITE

Proper management of stacker's area of travel can reduce the risk of accidents. The following basic precautions will contribute

to this :

- passageways must be kept in a good state of repair and free of obstructions,

- ramp gradients must not be too steep,

- pedestrian trac must be controlled.

THE OPERATOR

Only qualied, authorized personnel may use the stacker. This authorization is to be given in writing by the person in the

company, responsible for the use of the stacker, and must be carried by the operator at all times.

Experience has shown that there are a number of inappropriate ways in which the stacker might be used. Such

foreseeable misuse, of which the main examples are listed below, are strictly forbidden :

•The foreseeable abnormal behaviour resulting from ordinary negligence, but which does not result from any wish

to put the machinery to any improper use,

•The reex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the stacker,

•Behaviour resulting from application of the "principle of least eort" when performing a task,

•For certain machines, the foreseeable behaviour of such persons as : apprentices, teenagers, handicapped persons,

trainees tempted to operate a stacker, operators tempted to operate a stacker to win a bet, in competition or for their

own personal experience.

The person in charge of the equipment must take these criteria into account when assessing whether or not a person will

make a suitable operator.

THE STACKER

A - FITNESS OF THE STACKER FOR PURPOSE

MANITOU has ensured that this stacker is suitable for use under the standard operating conditions dened in this operator's

manual, with a STATIC test coecient of 1,33 and a DYNAMIC test coecient of 1, as specied in standard EN 1726-1 for industrial

trucks.

Before commissioning, the company manager must make sure that the stacker is suitable for the task to be performed,

and perform certain tests (in accordance with current legislation).

B - STACKER MODIFICATION

For your own safety and that of others, you must not change the structure and settings of the various components used in your

stacker by yourself (hydraulic pressure, limiter calibration, addition of extra equipment, unapproved tools, etc.). In this event,

the manufacturer cannot be held liable.

THE INSTRUCTIONS

The operator’s manual must be in good condition and available to the operator at all times.

Operator's manuals and any plates or stickers which are no longer legible or are damaged, must be replaced.

THE MAINTENANCE

Maintenance or repairs other than those detailed in part : 3 - MAINTENANCE must be carried out by qualied personnel (consult

your dealer) and under the necessary safety conditions to preserve the health of the operator and any third party.

Your stacker must be inspected periodically to ensure that it remains in compliance. The frequency of this inspection

is dened by the current legislation applying in the country in which the equipment is used.

1-6 STACKY operating and safety instructions 2012.12

1-7

STACKY operating and safety instructions2012.12

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

All the stackers and tools described in these instructions are standard stackers and standard tools respectively. The tools are only

interchangeable in the case of standard tools and standard stackers.

The risk of accident while using, servicing or repairing your stacker can be reduced if you follow the safety instructions

and safety measures detailed in this operator’s manual.

Only the operations and manoeuvres described in this operator's manual must be performed. The manufacturer cannot foresee

all possible hazardous situations. Consequently, the safety instructions given in the operator's manual and on the stacker itself

are not exhaustive.

As the operator, you must foresee at all times, within reason, the possible risk to yourself, to others or to the stacker itself when

you use it.

Failure to follow the safety and operating instructions, or the instructions for repairing or servicing your stacker may lead

to serious, even fatal accident.

GENERAL INSTRUCTIONS

A - OPERATOR'S MANUAL

Read the operator's manual carefully.

The instruction manual must always be kept in good condition and available to the operator.

You must report any plates and stickers which are no longer legible or which are damaged.

B - AUTHORISATION FOR USE

Only qualied, authorized personnel may use the stacker. This authorization is to be given in writing by the person

in the company, responsible for the use of the stacker, and must be carried by the operator at all times.

The operator has no authority to authorise the stacker to be operated by another person.

C - MAINTENANCE

The operator must immediately advise his superior if his stacker is not in good working

order or does not comply with the safety instructions.

Drivers are prohibited from carrying out any repairs or adjustments themselves, unless

they have received appropriate training. If appointed to do so, they are responsible for

keeping the stacker in a clean condition.

The operator is responsible for carrying out daily maintenance operations

(see : 3 - MAINTENANCE : A - DAILY CHECKS).

D - MODIFICATION OF STACKER

For your own safety and that of others, you must not change the structure and settings

of the various components used in your stacker by yourself (hydraulic pressure,

limiter calibration, addition of extra equipment, unapproved tools, etc.). In this event,

the manufacturer cannot be held liable.

E - LIFTING PEOPLE

The use of working equipment and load lifting tools to lift people is forbidden (g. E1).

F - STACKER DIRECTION OF TRAVEL

The stacker is travelling in the forward direction when the operator is holding the tiller

arm with one hand, and the stacker is behind him (g. F1).

F1

E1

1-8 STACKY operating and safety instructions 2012.12

UNLADEN AND LADEN STACKER OPERATING INSTRUCTIONS

A - PRIOR TO USING THE STACKER

Prior to using the stacker, the operator must check that there is no one within the danger zone (1.5 times the maximum stacker

lift height) and keep unauthorised persons outside this zone. It is, in particular, forbidden to stay close to moving parts.

If, in spite of a warning, people refuse to leave the danger zone, the operator must not continue using the stacker.

The operator must ensure that the stacker is in perfect working order by checking the following points :

- Operation of the brake with the tiller arm in the vertical position and in the horizontal position pushed downward,

- The operation of the key switch preventing unauthorised use of the machine,

- The tiller arm correctly returns to the vertical position,

- The stacker buttery control switches correctly return to the neutral position,

- The operation of the emergency stop button,

- The operation of the horn,

- The condition of the wheels and castors,

- The state of the fork arms or the tool, that must show no visible signs of damage (deformation, cracking or heavy wear)

and that they are correctly attached to the tool holder,

- The operation of the hydraulic system (lifting and lowering), and that the unladen fork or tool lowers smoothly and without

jamming,

- The cover is correctly in place,

- The state of charge of the battery and its connections,

- The built-in charger is no longer connected to the mains supply and that the lead is correctly stored,

- Visually check the condition and tension of the lifting chain,

- That the safety devices are correctly installed and operational.

The operator must stop using the stacker and inform his line manager if his stacker is not in good working order or does

not comply with the safety notice.

The operator must also check that the tool used is suitable for the loads to be handled.

B - DRIVER'S OPERATING INSTRUCTIONS

Whatever his experience, the operator is advised to familiarise himself with the position

and operation of all the controls and instruments before operating the stacker.

Wear clothes suited for operating the stacker, avoid loosely-tting garments.

Make sure you have the appropriate protective equipment for the task to be

performed.

Remain alert at all times when using the stacker. Do not listen to the radio or music

using headphones or earphones.

It is forbidden to sit on the stacker.

It is forbidden to carry passengers on the stacker (g. B1).

It is forbidden to push or tow a load with the stacker.

It is forbidden to brake suddenly and to make a turn at full speed.

C - ENVIRONMENT

This stacker is not designed to be used out of doors or to travel on the public highway.

The operator must comply with site safety regulations.

The stackers are only to travel along the aisles authorised by the company manager.

All aisles must be clearly marked. They must contain no tight bends or gradients, nor passages that are too narrow or too low.

The oor of the circulation aisles must be suciently strong, essentially at and horizontal, clean, non-slip and smooth.

The width of the circulation aisles must be at least 400 mm wider than the overall width of the stacker or of the load, if the load

is wider than the stacker.

Advance warning of obstacles or danger areas must be given by suitable markings.

Loads placed on the storage structures must not protrude and encroach on the circulation aisles.

Only authorised persons may access the circulation aisles.

During handling operations, make sure that there is no one obstructing the stacker and its load.

B1

1-9

STACKY operating and safety instructions2012.12

Do not allow anybody to approach the working area of the stacker or to pass beneath

the load (g. C1).

Take into account the stacker’s dimensions and its load before trying to negotiate

a narrow or low passageway.

Never move onto a loading platform without having rst checked :

- that it is suitably positioned and made fast,

- that the unit to which it is connected (wagon, lorry, etc.) will not shift,

- that this platform is able to support the total weight of the stacker to be loaded,

- that this platform is suitable for the size of the stacker.

Ensure that the gradients of the ramps do not exceed those shown in the table of

technical characteristics of the machines. A smooth transition of slope must be ensured,

to avoid rubbing and damaging the underside of the chassis.

Never move the stacker onto a foot bridge, oor or freight lift, without being certain

that they are suitable for the weight and size of the laden stacker and without having

checked that they are in good condition.

Be careful in the area of loading bays, trenches, scaolding, soft ground and manholes.

Make sure that the scaolding, loading platform, pilings or ground is capable of bearing

the load.

Never stack loads on uneven ground, they risk to be toppled. In the event of high winds,

do not carry out handling work that jeopardises the stability of the stacker and its load,

particularly if the load catches the wind badly.

D - VISIBILITY

The safety of people within the stacker’s working area, as well as that of the stacker itself

and the operator depend on good operator visibility of the stacker's immediate vicinity

in all situations and at all times.

When travelling in the forward direction, the load behind the operator must not impair

visibility (g. D1).

When manœuvring in reverse, if the size of the load restricts visibility, request the

assistance of a person directing the manoeuvre (while standing outside the stacker's

working area) being sure to keep this person clearly in view at all times.

E - SWITCHING ON THE STACKER

STACKY stackers are manually propelled, electric lift stackers.

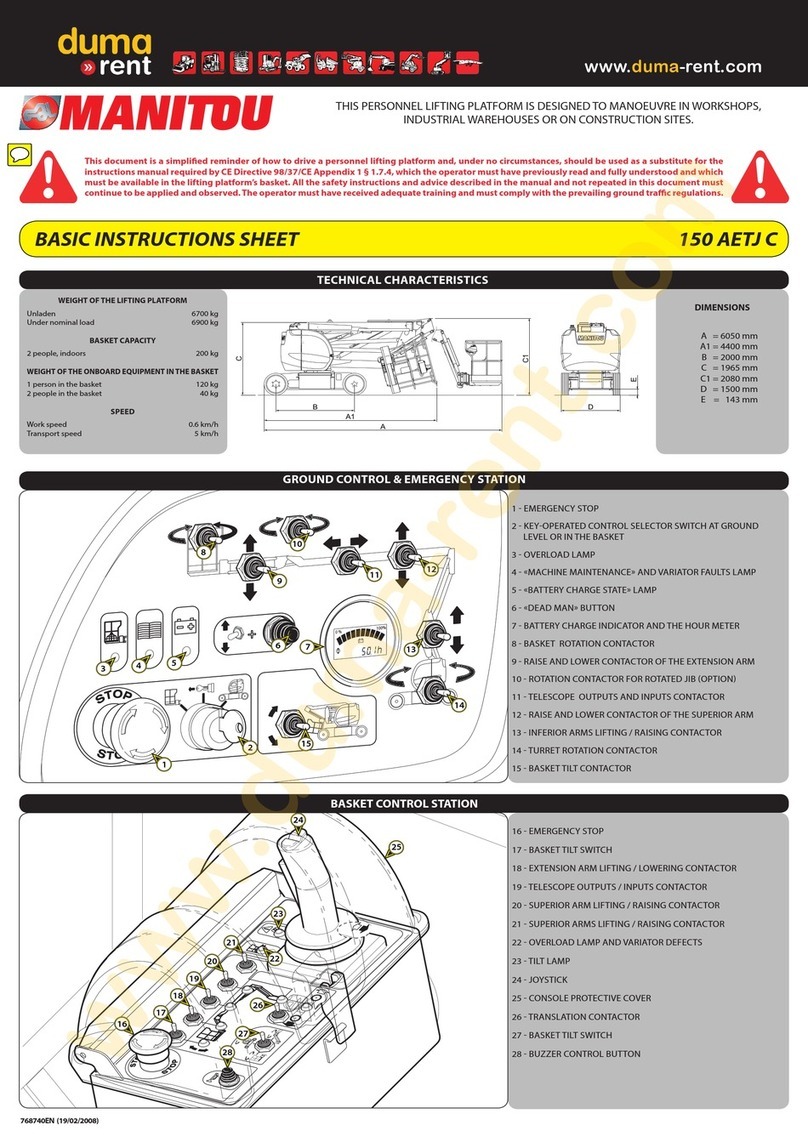

- Pull the red emergency stop button (3) (g. E1),

- Insert the key in the key switch and turn it clockwise to switch on the stacker

(2) (g. E1).

The multifunction display (1) (g. E1) indicates the battery charge level, as well as the

stacker operating time.

F - STACKER OPERATION

SAFETY INSTRUCTIONS

The operators' attention is drawn to the risks involved in using the stacker,

in particular :

•Risk of loosing control,

•Risk of loosing lateral and frontal stability of the stacker.

The operator must remain in control of the stacker.

It is strictly forbidden to touch the moving components (tools, moving frame,

lifting chain, etc.) or to place the hands in the masts (g. F1).

Follow the company’s trac rules.

- Do not carry out operations which exceed the capacities of your stacker or the tool,

- The stacker must be moved with the forks or the tool in the down position,

i.e. 150 mm from the ground (g. F2),

- The loads carried must be balanced and correctly secured to avoid the risk of falling,

- Ensure that palettes, cases, etc, are in good order and suitable for the load to be lifted,

- Familiarise yourself with the stacker on the site where it will be used,

- Ensure that the service brakes are working properly,

- The speed of travel of the laden stacker must be adapted to the internal trac

conditions,

VOLTS

28

22

19

16

-+

23

1E1

D1

150 mm

F2

F1

C1

1-10 STACKY operating and safety instructions 2012.12

- Move the stacker smoothly at an appropriate speed for the operating conditions

(ground prole, load on the stacker),

- Do not use the lifting or lowering controls when the lift truck is moving,

- Approach bends, narrow passages or swing doors, as well as any sector where

visibility is reduced, at reduced speed,

- Make sure you are in control of your speed under all circumstances,

- Brake gently, never abruptly,

- Do not leave the stacker unattended with the load raised (g. F3),

- Look where you are going and always make sure you have good visibility along

the route,

- Leave a margin of safety when manoeuvring around obstacles,

- The operator must always remain uphill of the stacker on a ramp,

- Ramps must not be taken perpendicular to the axis of the slope,

- Never turn the stacker around on a ramp.

The operator must not move the stacker with the fork or tool in the raised position,

whether laden or unladen (g. F4).

The operator must not pass the load over a person when moving the stacker (g. F5).

INSTRUCTIONS

- Always move the stacker with the forks or tool in the transport position, i.e. at 150

mm from the ground,

- Place the tiller arm within the driving zone (2) (g. F6) in order to unlock the electrical

safety system,

- The orientation of the tiller arm determines the direction of the stacker,

- When moving the stacker, the operator must walk in front of the machine,

- Gradually push one of the buttery control switches up or down (1) (g. F7)

depending on the chosen direction of travel.

As the stacker is tted with an electronic speed controller, its speed is progressive and

increases according to the angular position of the buttery control switch.

- To brake the stacker, release the buttery control switch, which will return to the

neutral position, gradually bringing the stacker to halt,

- To stop the stacker, fully lower or raise the tiller arm (1) (g. F6) or (3) (g. F6), which

will actuate the electrically-operated brake.

The tiller arm automatically returns to the vertical position as soon as it is released.

The parking brake is then operated, stopping the stacker immediately.

The end of the tiller arm is tted with an anti-crushing safety device (2) (g. F7) that

protects the operator by reversing the direction of travel as soon as it is pressed. The

stacker will only stop when the pressure on the safety device stops or after 5 seconds.

This only applies when the stacker is in forward mode.

The button with a tortoise symbol (3) (g. F7) moves the stacker at slow speed. This

function is very useful when manœuvring in conned spaces. When the button is

activated, the stacker travels at 30 % of its nominal speed. This function can be used

regardless of the control lever position (brake or drive).

- Hold down the slow speed (tortoise) button (3) (g. F7),

- Push the buttery control switch up or down (1) (g. F7) according to the chosen

direction of travel.

F4

F5

1 2

1

3

F7

F3

3

2

1

F6

1-11

STACKY operating and safety instructions2012.12

G - STOPPING THE STACKER

SAFETY INSTRUCTIONS

- When the stacker is stationary, or if the operator has to the leave the operator’s

position (even for a moment), place the forks or tool in the down position.

INSTRUCTIONS

- Park the stacker on level ground,

- Place the fork or tool in the down position (g. G1),

- Turn the key anti-clockwise (1) (g. G2),

- Remove the key,

- Push the emergency stop button (2) (g. G2).

H - CHARGING THE BATTERY

SAFETY INSTRUCTIONS

The battery must be charged, serviced and replaced by experienced persons.

It is formally forbidden to smoke or use a ame nearby when performing these

operations.

Never place metal objects on the battery.

Bracelets, chains or watches must not be worn to avoid accidental shot circuits.

All the operations described above must be carried out with the machine shut down

(the multifunction display will be switched OFF in this case).

INSTRUCTIONS

Charging must be carried out in a well-ventilated space. Check that there are no

ammable materials or machines generating sparks within a 2 m radius around

the machine during charging.

Fire protection equipment is to be made available nearby.

- Unplug the charging lead (1) (g. H1) from the dummy socket on the fork side

and connect it to a 220V - 50 Hz - 10 A single phase socket.

The charger is tted with an indicator lamp (2) (g. H1), the colour of which indicates

the dierent levels of battery charge (g. H2) :

• the indicator lamp is red during the initial charging phase,

• the indicator lamp is yellow when the battery reaches 80 % charge,

• the indicator lamp is green when the battery is fully charged.

- Unplug the charging lead and reconnect it to the dummy socket, taking care

to return the lead to its housing.

CAUTION : When the mains lead is disconnected from the dummy socket

(1) (g. H1), all of the stacker’s controls will be disabled. The operator must the-

refore reconnect the mains lead to the dummy socket in order to use the stacker.

If charging is carried out at night, check that the current is not switched o by the

general shut-down of the establishment.

Never discharge a battery beyond 80 %,

The dashboard indicator signals this level of charge by means of two alternately ashing red LEDs. The battery then

needs recharging.

G1

VOLTS

28

22

19

16

-+

12

G2

H2

1

2

H1

1-12 STACKY operating and safety instructions 2012.12

INSTRUCTIONS FOR HANDLING A LOAD

A - CHOICE OF TOOL (EXCEPT STACKY 14)

Only tools approved or authorised by the manufacturer are to be used on its stackers.

Check that the tool is appropriate for the task to be performed.

Certain specic applications require non-standard stackers to be used. These stackers have dedicated tools that

are not interchangeable.

Make sure the tool is correctly installed and secured to the stacker’s carriage.

Make sure that your stacker tools work properly.

Do not exceed the rated capacity of the tool.

Never lift a load in a sling without the tool intended for this purpose, as the sling risks to

slip (see : INSTRUCTIONS FOR HANDLING A LOAD : G - TAKING UP AND LAYING DOWN

A SUSPENDED LOAD).

B - WEIGHT AND CENTRE OF GRAVITY OF THE LOAD

You must know the weight and the centre of gravity of the load before you pick it up.

Never lift a load without knowing its weight and centre of gravity.

The maximum lifting capacity is indicated on the name plate located on the right-hand

side of the stacker’s xed mast.

The eective load capacity and the centre of gravity of the load are specic to the tool

tted on the stacker. These values are indicated on each tool’s name plate.

The lifting height and the centre of gravity dictate the maximum load that can be lifted.

These values are indicated on the stacker manufacturer’s plate located under the tiller

arm.

For irregularly shaped or asymmetric loads, determine the centre of gravity in the

transverse direction before handling and position the centre of gravity within stacker’s

longitudinal centreline (g. B1 et B2).

It is forbidden to directly place onto the fork or the tool, by external means, a load that

exceeds the eective capacity.

It is forbidden to move a load heavier than the eective capacity indicated

on the tool manufacturer's plate.

For loads with a moving centre of gravity (such as liquids), take account of the

variations in the centre of gravity in order to determine the load to be handled

and be vigilant and take extra care to limit these variations as far as possible.

C - PICKING UP A LOAD ON THE GROUND

- Approach the stacker perpendicular to the load, with the forks in the down position

(g.C1),

- Position the stacker on the centreline of the load, unless the volume of the load

is asymmetric (g. C2),

- Insert the fork under the load as far as it will go,

- Raise the load.

The load must be perfectly balanced, wedged or tied to its support to avoid any risk

of slipping or overturning.

Never lift a load from which certain elements could become detached and injure

the operator.

Never lift a load with a single fork arm.

Never lift a person with the stacker.

The operator must ensure that the arms are suciently widely spaced to ensure

the stability of the load.

The load must not extend more than 50 mm beyond the end of the fork.

The width of the load must not exceed two times the maximum external width

of the fork.

When using adjustable forks, beware of the risk of the risks of trapping

or crushing limbs when manually adjusting the arms of the forks.

CdG

B1

B2

C1

C2

1-13

STACKY operating and safety instructions2012.12

D - PICKING UP AND SETTING DOWN A LOAD

Lifting and lowering are controlled by means of two buttons situated on the tiller

arm (1) and (2) (g. D1). These controls are duplicated to be equally accessible for left

or right hand use.

- To lift the load, press button (1) (g. D1),

- To lower the load, press button (2) (g. D1).

E - SETTING-DOWN A LOAD IN A STORAGE STRUCTURE

- As you approach the storage structure, slow the stacker to arrive at moderate speed,

- Position the stacker in front of its storage location,

- Check that no obstacle risks to be caught by the load, the fork or the tool during

lifting,

- Raise the load so that the underside is higher than the bearing surface (1) (g. E1).

Check that, when it is inserted into its housing, the load does not risk to catch any

lateral or horizontal part of the support structure.

- Operate a buttery control switch to move slowly forward until the load is above

its intended position, taking care not to knock against the storage structure with

the stacker (2) (g. E2),

- Slowly set down the load (3) (g. E3),

- Check the lifting chain tension : if it is slack, the fork is resting on the storage

structure. Raise the fork slightly by lightly pressing the UP button,

- Ensure that the area of manoeuvre is unobstructed,

- Slowly reverse the stacker by operating a buttery control switch to release the fork

(4) (g. F3), checking that it will not catch any obstacle as it is lowered,

- Lower the fork or tool into the down position.

In order to avoid the risk of destabilising or overturning the stacker during these

operations, take care not to :

•catch the load or tool,

•hit the bearing surface with the fork or the tool,

•drag the fork or tool across the bearing surface.

3

4

E3

2

E2

12

2

D1

1

E1

1-14 STACKY operating and safety instructions 2012.12

F - PICKING UP A LOAD IN A STORAGE STRUCTURE

- As you approach the storage structure, slow the stacker to arrive at moderate speed,

- Position the stacker in front of its storage location,

- Check that no obstacle risks to be caught by the fork or the tool as it is raised,

- Raise the fork so that the underside is slightly higher than the bearing surface

(1) (g.F1),

- Operate a buttery control switch to move slowly forward and insert the fork under

the load up to its heel (2) (g. F2), taking care not to knock against the storage

structure with the stacker. During this operation, the fork must not rub against the

bearing surface or the underside of the load (in which case the lifting belt would

slack).

The centre of gravity of the load must be located on the centreline of the stacker.

- Slowly raise the load until it is lofted o the bearing surface (3) (g. F2),

- Ensure that the area of manoeuvre is unobstructed,

- Slowly reverse the stacker to release the fork (4) (g. F3), checking that it will not

catch any obstacle as it is lowered,

- Lower the load (5) (g. F3) into the transport position, 150 mm from the ground.

In order to avoid the risk of destabilising or overturning the stacker during

these operations, take care not to :

•catch the load or tool,

•hit the bearing surface with the fork or the tool,

•drag the fork or tool across the bearing surface.

G - PICKING UP AND SETTING DOWN A SUSPENDED LOAD (EXCEPT STACKY 14)

The stacker must be tted with a special protective device when using the jib

arm tool : a non-return valve kit.

WARNING : Failure to follow the above instructions may lead the stacker to loose

stability and overturn.

CONDITIONS OF USE

- Jib arm is only to be used by trained personnel,

- The jib arm is only to be used indoors, on a at, horizontal and smooth oor

and windless conditions,

- The load capacity must be halved relative to the stacker’s rated load capacity

(the jib arm characteristics take account of this),

- The length of the sling or the chain shall be as short as possible to limit swinging

of the load,

- Lift the load vertically along its axis, never by pulling sideways or lengthways (g.G1).

HANDLING WITHOUT MOVING THE STACKER

- Ensure that there is no one between the load and the stacker.

1

F1

2

3

F2

4

5

F3

G1

1-15

STACKY operating and safety instructions2012.12

H - TRAVELLING WITH A SUSPENDED LOAD (EXCEPT STACKY 14)

- Carry the load in the down position (max. 150 mm from the ground) with the shortest

possible boom length (g.H1),

- Secure the load (1) (g. H1),

- Take all precautions when moving high loads,

- The stacker must not travel at more than 0,4 m/s (1,5 km/h, i.e., one quarter walking

speed),

- Move and stop the stacker gently and smoothly to minimise swinging of the load.

If the load starts to swing, do not hesitate to stop and lower the jib to set down the load.

h ≤150 mm

mini

1

H1

1-16 STACKY operating and safety instructions 2012.12

STACKER MAINTENANCE INSTRUCTIONS

GENERAL INSTRUCTIONS

Wear clothes suitable for the maintenance of the stacker, avoid wearing jewellery and loose clothes.

Read the operator's manual carefully.

Carry out all necessary repairs at the earliest possible opportunity, even if the repairs concerned are minor.

Repair all leaks at the earliest possible opportunity, even if the leak concerned is minor.

Ensure that consumable materials and worn parts are removed and disposed of in accordance with current environmental

protection decrees.

MAINTENANCE

Perform the periodic service (see : 3 - MAINTENANCE) to keep your stacker in good working conditions. Failure to perform

theperiodic service may annul the contractual guarantee.

MAINTENANCE LOGBOOK

The maintenance operations carried out in accordance with the recommendations given in part : 3 - MAINTENANCE and the

other inspection, servicing or repair operations or modications performed on the stacker or its tools shall be recorded in a

maintenance logbook. The entry for each operation shall include details of the date of the works, the names of the individuals or

companies having performed them, the type of operation and its frequency, if applicable. The part numbers of any stacker items

replaced shall also be indicated.

HYDRAULIC

Any work on the load handling hydraulic circuit is forbidden except for the operations described in part : 3 - MAINTENANCE.

Do not attempt to loosen couplings, hoses or any hydraulic component with the circuit under pressure.

ELECTRICITY

Do not place metal items on the battery.

Disconnect the battery before working on the electrical circuit.

FOR ANY OPERATIONS OTHER THAN REGULAR MAINTENANCE OPERATIONS, CONSULT YOUR DEALER

This manual suits for next models

4

Table of contents

Other Manitou Lifting System manuals

Manitou

Manitou MI-X 50L D C ST3A S2 User manual

Manitou

Manitou 80 VJR User manual

Manitou

Manitou PRIVILEGE MRT 1850 PLUS-E3 Mounting instructions

Manitou

Manitou 100 SC-2 User manual

Manitou

Manitou 150 AETJ C User manual

Manitou

Manitou 150 AETJ C User manual

Manitou

Manitou MT 728 User manual

Manitou

Manitou TMT 25 I 2-E3 Series User manual

Manitou

Manitou MI 80 D ST4 S2 User manual

Manitou

Manitou 150 AETJ C User manual