INSTRUCTIONS FOR:

MOTORCYCLE LIFT 365kg AIR

MODEL No: MC365A

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS

JACK CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

Thank you for purchasing a Sealey jack. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

Disconnect lift from air supply before changing parts, servicing or performing any maintenance.

WARNING! Ensure correct air pressure is maintained and not exceeded. Recommended pressure 120-200psi. Required air flow 9.5cfm.

Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections are secure.

Ensure lift is kept clean and in good working order. Immediately repair or replace damaged parts.

Use recommended parts only. Incorrect parts may be dangerous and will invalidate the warranty.

Use a qualified person to lubricate and maintain the lift. DO NOT use brake fluid to top up system. Use Sealey hydraulic oil only.

Locate lift in a suitable, well lit work area. Keep area clean and tidy and free from unrelated materials.

Use lift on level and solid ground, preferably concrete. Avoid tarmacadam since lift may sink in.

Ensure all nonessential persons keep a safe distance.

Always keep your hands and feet away from moving parts.

DO NOT operate the lift if parts are missing or damaged.

DO NOT use the lift for purposes other than that which it is designed for.

DO NOT adjust the safety overload valve.

Use a qualified person to maintain the lift in good condition. Keep it clean for best and safest performance.

The maximum load is 365Kg. DO NOT exceed this rated capacity.

Use this lift for lifting purpose only. DO NOT use it for any other purpose it is not designed to perform.

Keep children and unauthorised persons away from the work area.

Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellry, and contain long hair.

Keep proper balance and footing, do not overreach and wear nonslip footwear.

Only use this lift on a surface that is stable, level, dry and capable of sustaining the load.

Ensure the motorcycle is adequately secured to the lifting platform with appropriate straps.

When the platform has been raised to the working height, ensure the locking bar is engaged to prevent accidental lowering.

Before lowering lift ensure that there are no obstructions underneath and that all persons are standing clear.

DO NOT attempt to transport a load on the lift. The lift must only be used in a static position for lifting and lowering loads. Ensure that the load

remains stable at all times.

DO NOT use the lift if damaged, any suspect parts are noted or it has been subjected to a shock load.

DO NOT operate the lift when you are tired or under the influence of alcohol, drugs or any intoxicating medication.

DO NOT allow untrained persons to operate the lift.

DO NOT make any modifications to the lift.

DO NOT get the lift wet.

DO NOT yank the hose from the air supply, and DO NOT direct air from the air hose at yourself or others.

When not in use disconnect lift from the air supply, and store in the down position in a safe, dry, childproof area.

WARNING: The warnings, cautions and instructions discussed in this instruction manual cannot cover all possible conditions and

situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be applied by the operator.

1. SAFETY INSTRUCTIONS

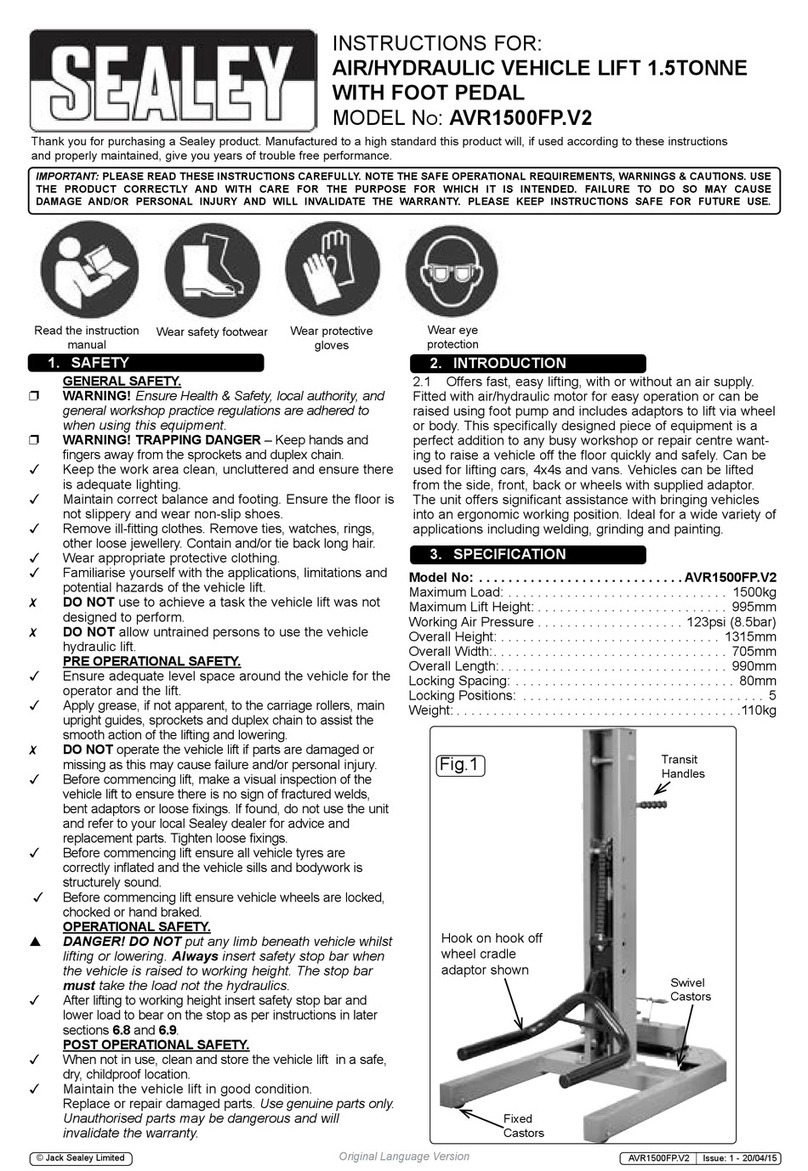

2. SPECIFICATION

Capacity 365kg

Min. height 220mm

Max. height 760mm

Air pressure

Air supply fitting

Max. load length

Overall length

Width

(platform only) 1350mm

(inc. ramp) 2215mm

480mm

Min.120psi / Max. 200psi

1/4”BSP

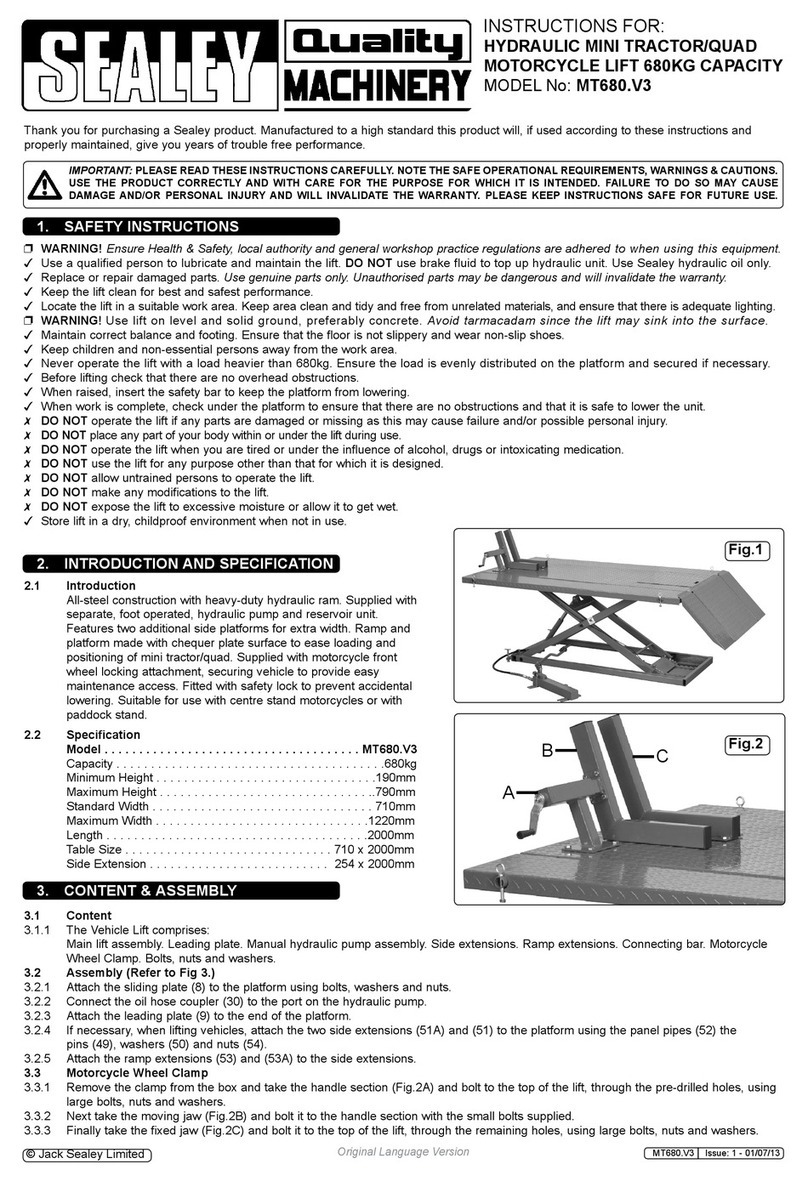

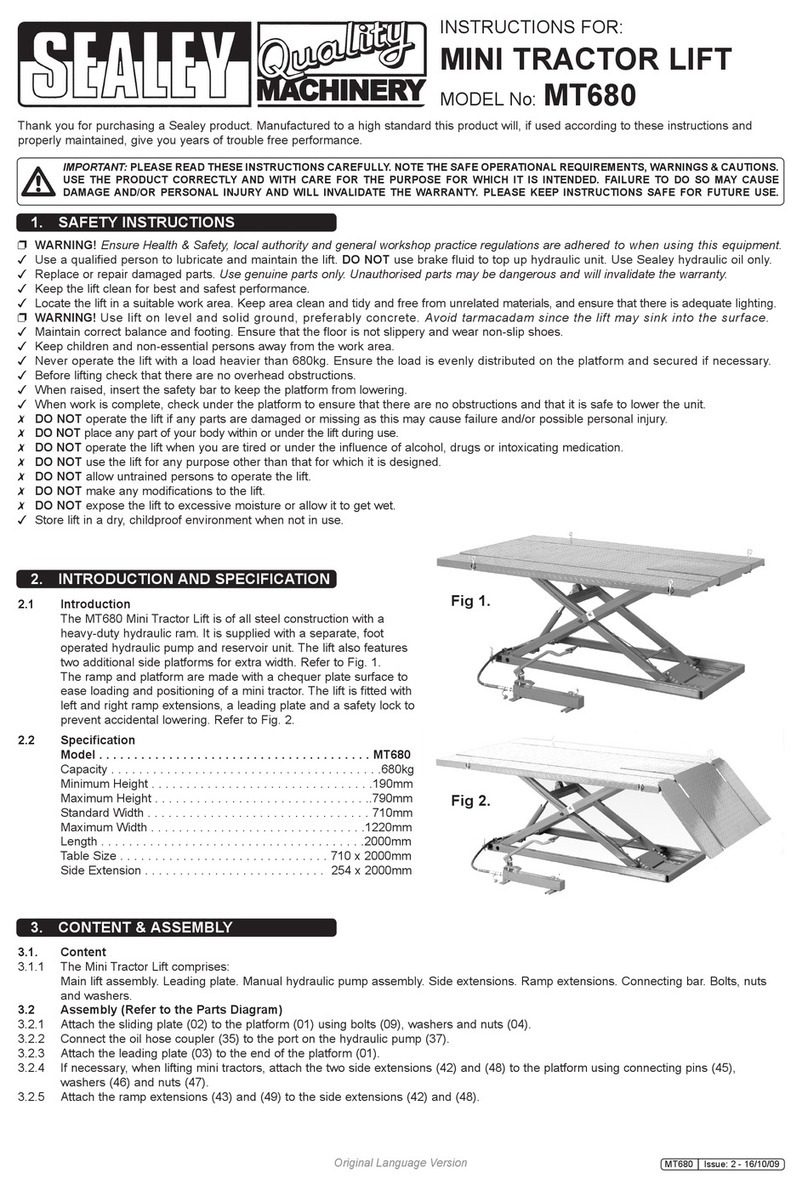

All steel construction with air motor powering the hydraulic pump. Safety lock device for preventing accidental lowering and front wheel clamp assists

to secure motorcycle. Support platform fitted with full width loading ramp. Base assembly fitted with transport wheels and lock down to prevent lift from

moving during use.

Original Language Version MC365A Issue: 3 - 01/06/11