3

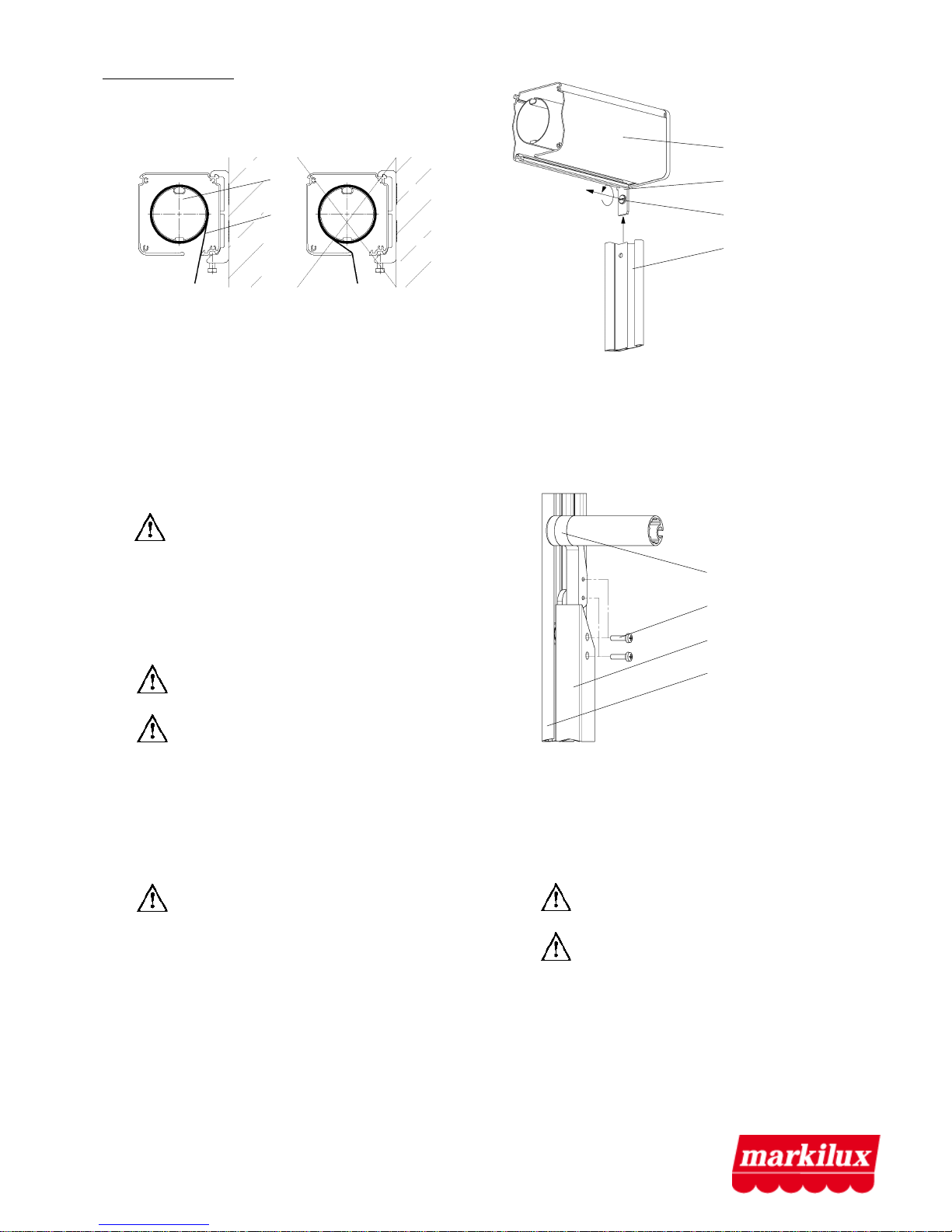

tional drillings have to be made laterally in the

rails.

There are grooves in the rails to make it easier for

the customer to make drillings in the same dis-

tances as the drillings already in place.

Mounting drillings in the angled guide rails for the

max. screw size for niche mounting drive and/or

motor:

Attention: It has to be observed for the niche

mount hat only countersunk-head screws that do

not protrude are used, as the the downpipe is

guided in he groove.

3. Motor connection

The lead-in for the motor and the control connec-

tion has to be installed and connected by an ap-

proved electrician (as per VDE 0100). The connec-

tion has to be executed acc. to the regulations of

the manufacturer of the motor/controller.

Modifications, especially concerning the motor, the

controller and the connecting supply lines require

our authorization.

Cable exit on motor driven units

Attention:

3.1 For the unmonitored operation of the electro-

motive powered mini-awning with automatic

control the following has to be observed:

If the mounting height of moveable parts of the

window awning to the circulation are is less

than 2.5 m, special safety measures have to be

taken in order to prevent possible injuries

(mech. shielding, overload protection, contact

strip, photocell, etc).

No persons and obstacles should be within the

extension and retraction range of the awning!

Special care has to be taken for accessible areas

in which children could be.

3.2 For the operation of a electromotive powered

mini-awning with manual switch the extension

and retraction motion has to be stoppable and

permanently controllable by the user, if the

awning is in an accessible area and the safety

distance of 2.5 m, described under point "3.1"

cannot be adhered to. In this case switch push

buttons have to be used permitting by simply

omitting the operation button thus enabling a

stop of the extension and retraction motion

(principle of dead man's switch).

3.3 The automatic operation of the awning must

not lead to falls of persons possibly working at

the facade. An overriding switching locking de-

vice or blocking barrier has to make impossible

any adjustment of the awning if there are works

taking place at the building facade.

Setting the motor end switch:

Attention: The built-in motor has a set end

stop both in the extension and retraction direction.

These settings were effected in the factory. They

always have to be checked on site, as the end stops

might have shifted e.g. through strong vibrations

during transport or the motor does not switch off

anymore. For any changes or corrections of these

settings please refer to the instructions of the

motor.

The installation and setting instructions are indi-

cated on the motor's power supply cable. When

setting remote-controlled motors please start with

point "factory"-programming of the instruction

manual!

Attention: The rolling up of the fabric on the

fabric roller from top during retraction could result

in damage to the awning fabric and the awning

frame. When setting the end positions of the motor

it is important to ensure that the fabric winds up as

shown during the retraction process: