markilux safety instructions

Important information for the installation of markilux awnings

markilux

If the awning construction has to be pulled up into a higher area with

rope support, then the awning has

• to be taken out of the package,

• should be connected with pull ropes in such a way that these

cannot slip out,

• are to be pulled up up evenly in an horizontal position.

The same also applies for awning deinstallation.

Working at heights increases the risk of falling.

Appropriate climbing aids and safety rails are to be used whilst

installing the awning.

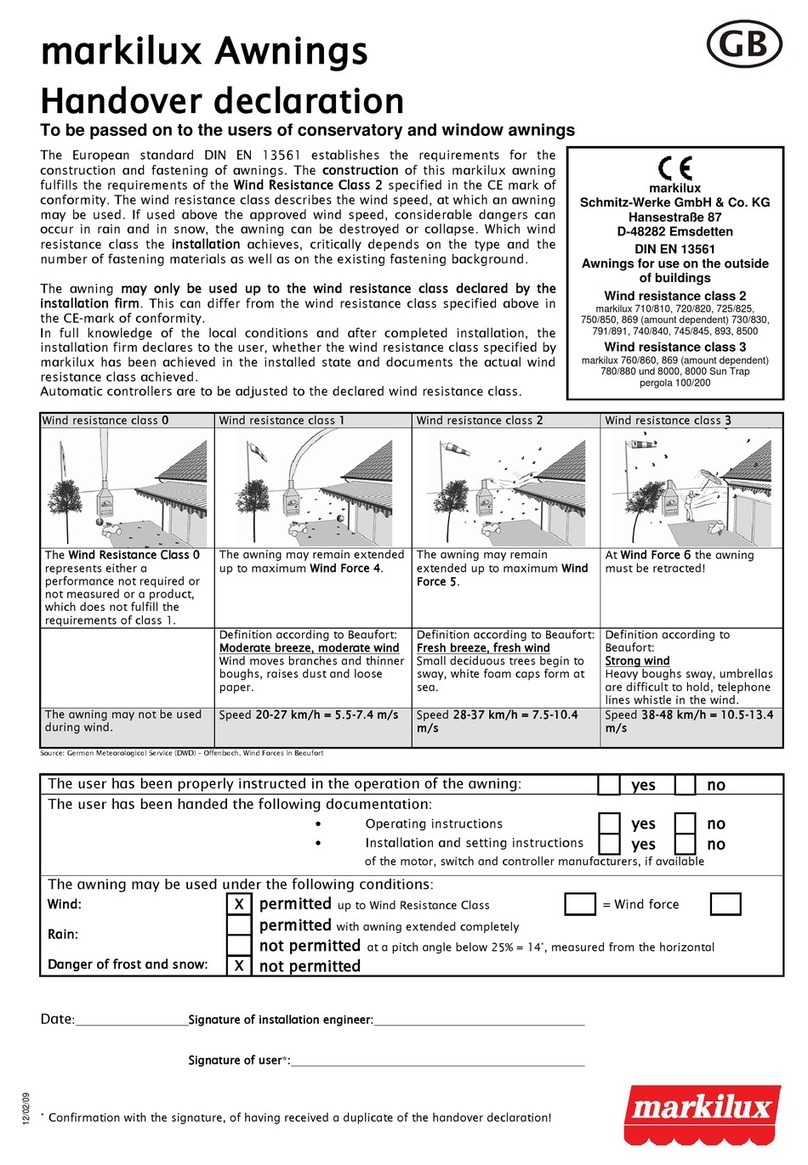

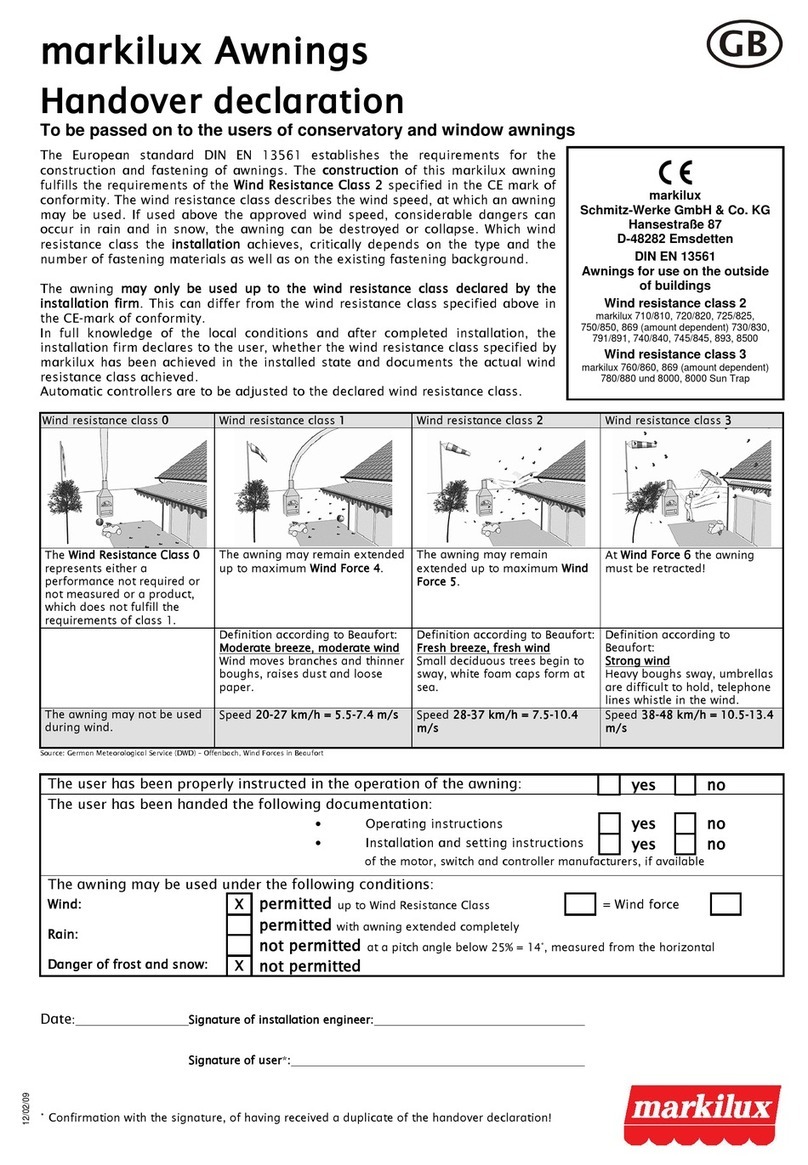

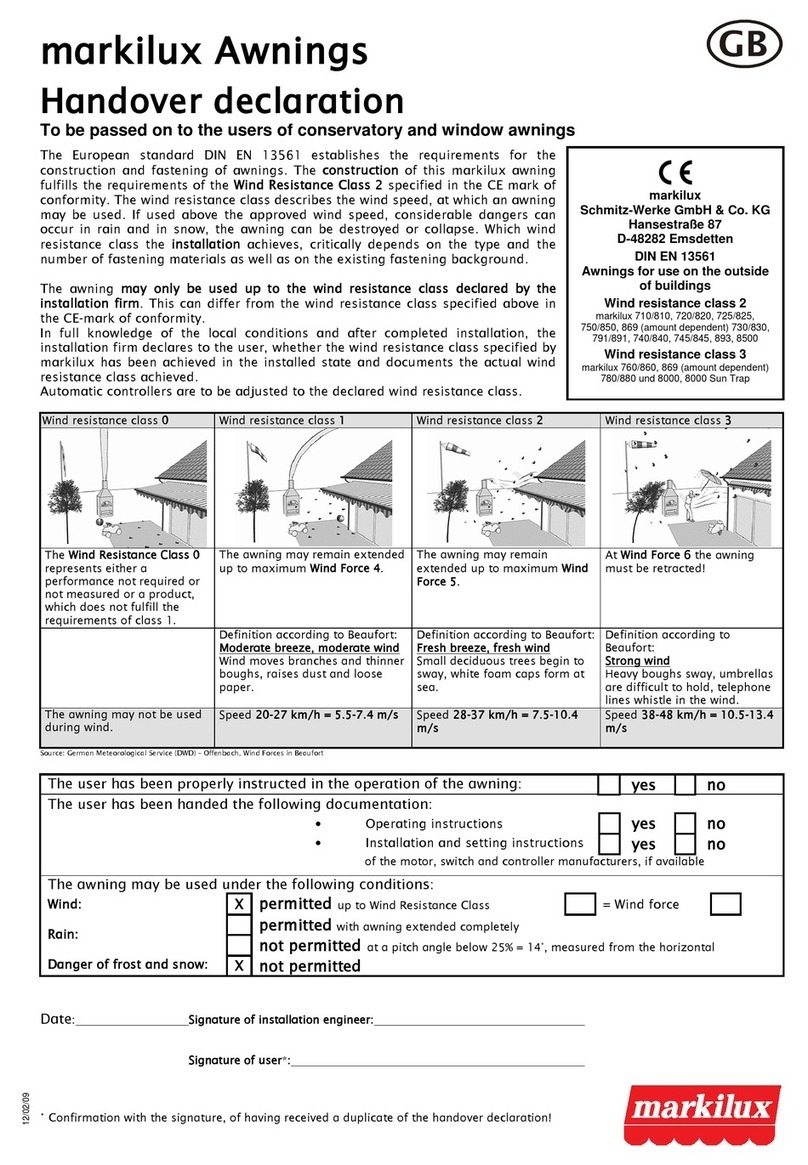

5. Wind resistance classes

markilux

Schmitz-Werke GmbH & Co. KG

Hansestraße 87

D-48282 Emsdetten

DIN EN 13561

Awnings for exterior applications

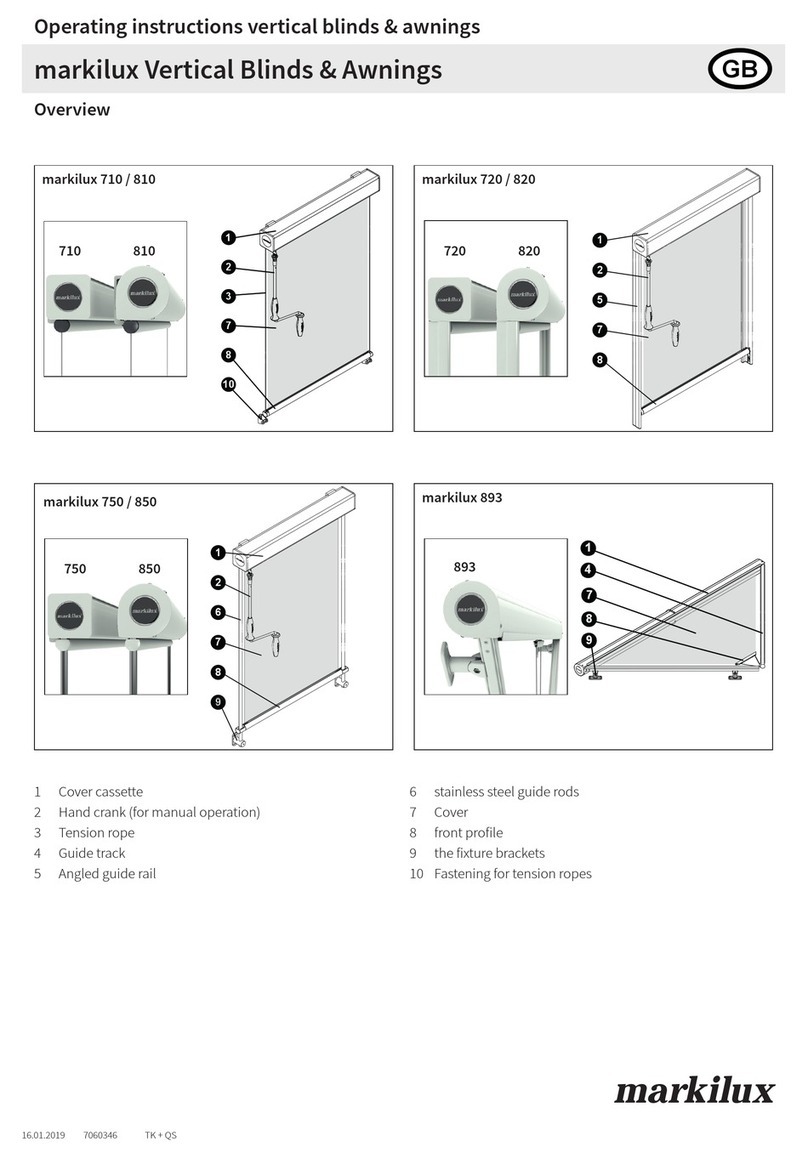

wind resistance class 2

markilux folding-arm awnings

markilux 710/810, 720/820, 725/825,

750/850, 730/830, 740/840, 745/845,

893, 869/869 zip/889/889 zip

(depending on size), 8850

wind resistance class 3

markilux 760/860, 620 zip, 660 zip,

680 zip, 780/880, 8800/8800 zip,

869/869 zip/889/889 zip (depending

on size), pergola 110/210

The awning fullls the requirements of the wind resistance class

specied in the CE conformity marking (explanations see „handover

declaration“).

In assembled condition, it only fullls these requirements if...

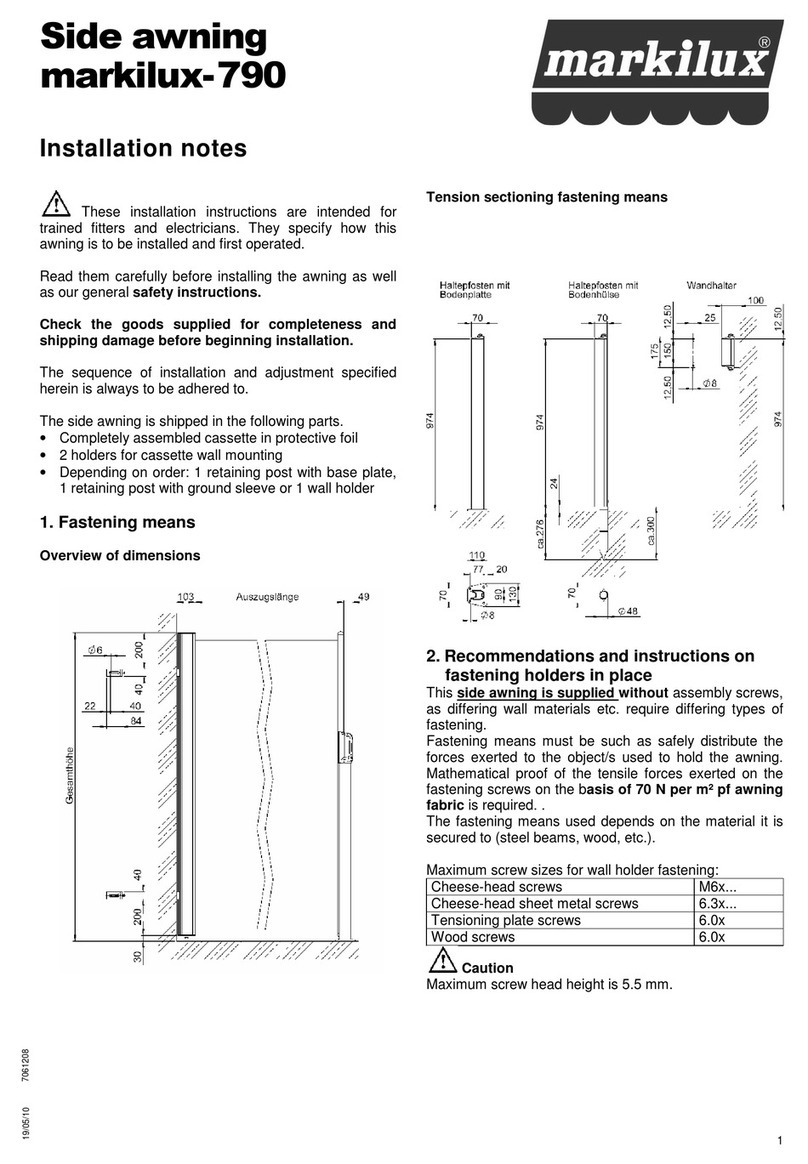

• ... the awning is mounted in accordance with the type and number

of consoles recommended by the manufacturer.

• ... the instructions of the xing material manufacturer regarding the

used dowels were followed during the assembly.

• ... the installation of folding-arm awnings was carried out

considering the

1.Who is allowed to t markilux awnings?

The markilux installation instructions are to a qualied mechanic who

has skilled knowledge in following domains:

• Occupational and operational safety and accident prevention

regulations

• Handling of ladders and scaffoldings

• Handling and transport of long and heavy component parts

• Handling of tools and machines

• Fixture device placement

• Assessment of building materials

• Commissioning and operation of the product

If any one of these qualications is not existent, a qualied installation

rm must be engaged.

Electrical works: electrical installations must be carried out by

a certied electrician according to VDE 0100. The enclosed

installation instructions of the supplied electronic devices are to be

observed.

We recommend installation be carried out by at least two people.

Larger awnings may require three persons.

2. Before beginning the installation it is to be checked, ...

• does the number and type of xture brackets match the order?

• do the specications made with the order concerning the fastening

background correspond with the actual fastening background at

hand (only for folding-arm awnings)?

If irregularities which may affect the safety of the unit or its users are

determined, then the installation must not be undertaken.

3. Reading and passing on the instructions

The security and attachment notes as well as the operation manuals

are to be read and observed!

The markilux operating guide, as well as the setting instructions of the

motor, switch and controller manufacturers are to be handed over to

the user with a written conrmation and tted wind class (see

handover declaration). He is to be comprehensively informed about

the safety and usage information of the awning. With nonobservance

and improper operation, the awning can suffer damage and accidents

can occur.

4. Working at greater heights