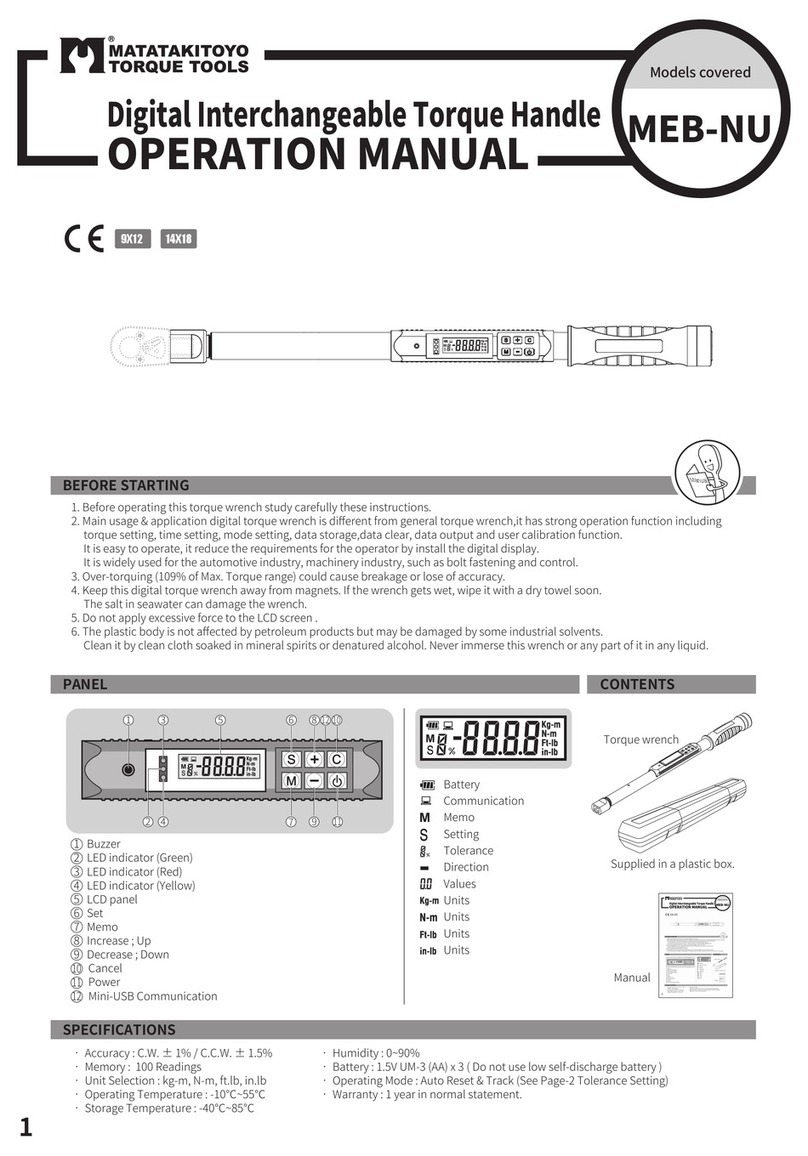

Nm

HW

ØD

L

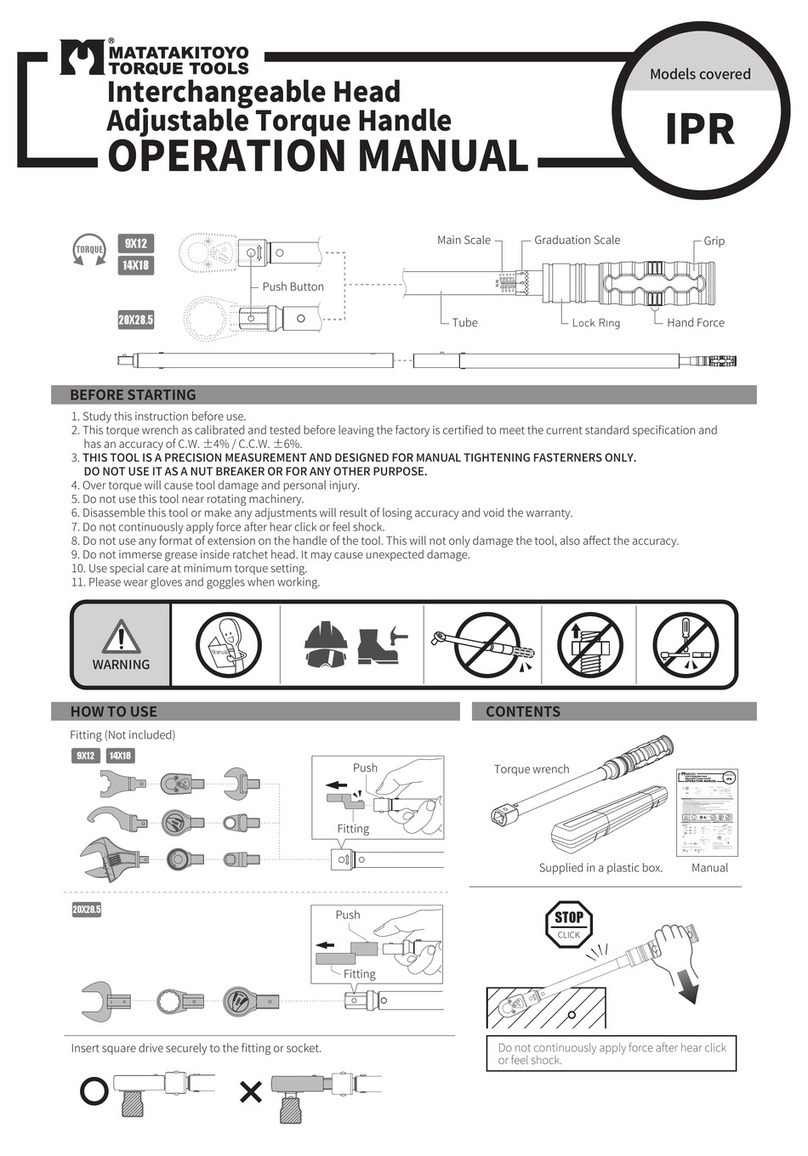

9x12

9x12

9x12

14x18

9x12

14x18

14x18

14x18

MIT-15N

MIT-30N

MIT-60N

MIT-60NS

MIT-100N

MIT-100NS

MIT-200N

MIT-300N

0.4 Nm

1 Nm

4 Nm

4 Nm

5 Nm

5 Nm

5 Nm

0.5 Nm

3-15 Nm

5-30 Nm

12-60 Nm

12-60 Nm

20-100 Nm

20-100 Nm

40-200 Nm

60-300 Nm

ØD

20.7

30.5

30.5

30.5

30.5

30.5

34.1

34.1

L

188

290

365

375

420

430

500

580

H

16.7

16.2

19.0

22.0

16.2

22.0

24.5

24.5

W

23.9

24.1

24.1

32.9

23.9

32.0

32.2

32.2

20.7

30.5

30.5

30.5

30.5

30.5

34.1

34.1

188

290

365

375

420

430

500

580

16.7

16.2

19.0

22.0

16.2

22.0

24.5

24.5

23.9

24.1

24.1

32.9

23.9

32.0

32.2

32.2

0.22

0.58

0.80

0.81

1.14

1.15

1.38

1.50

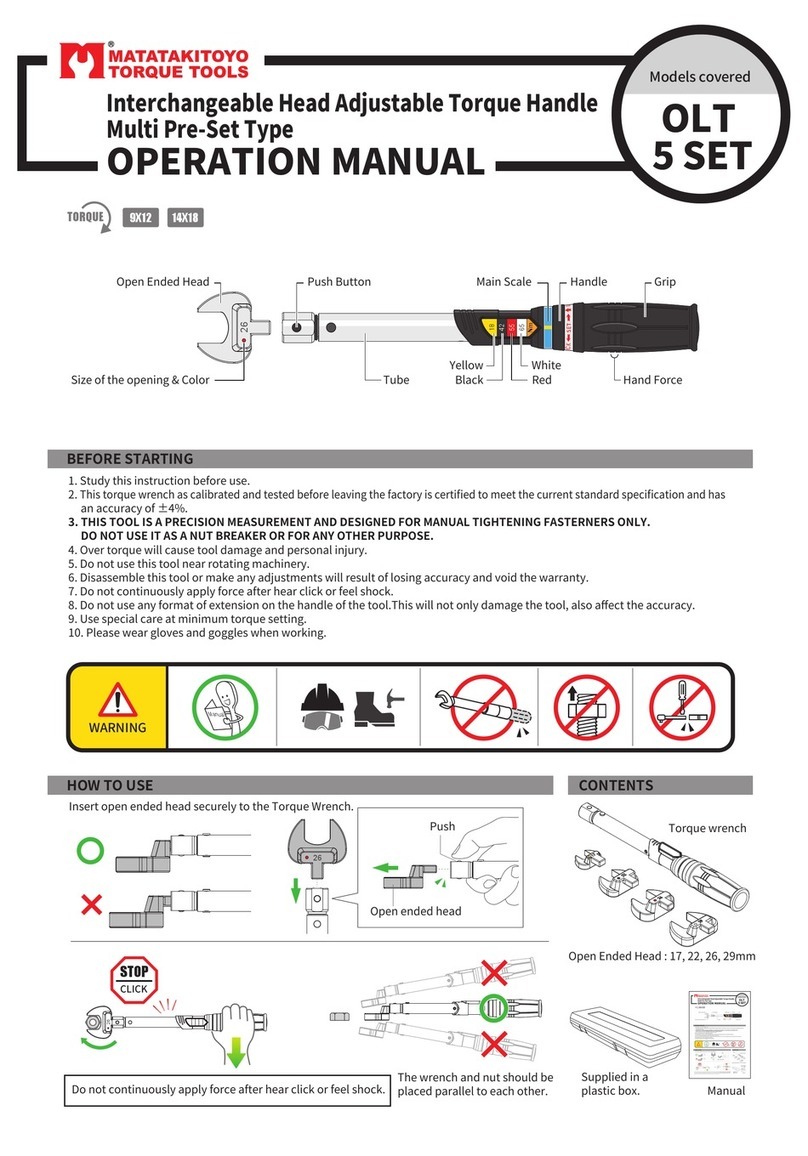

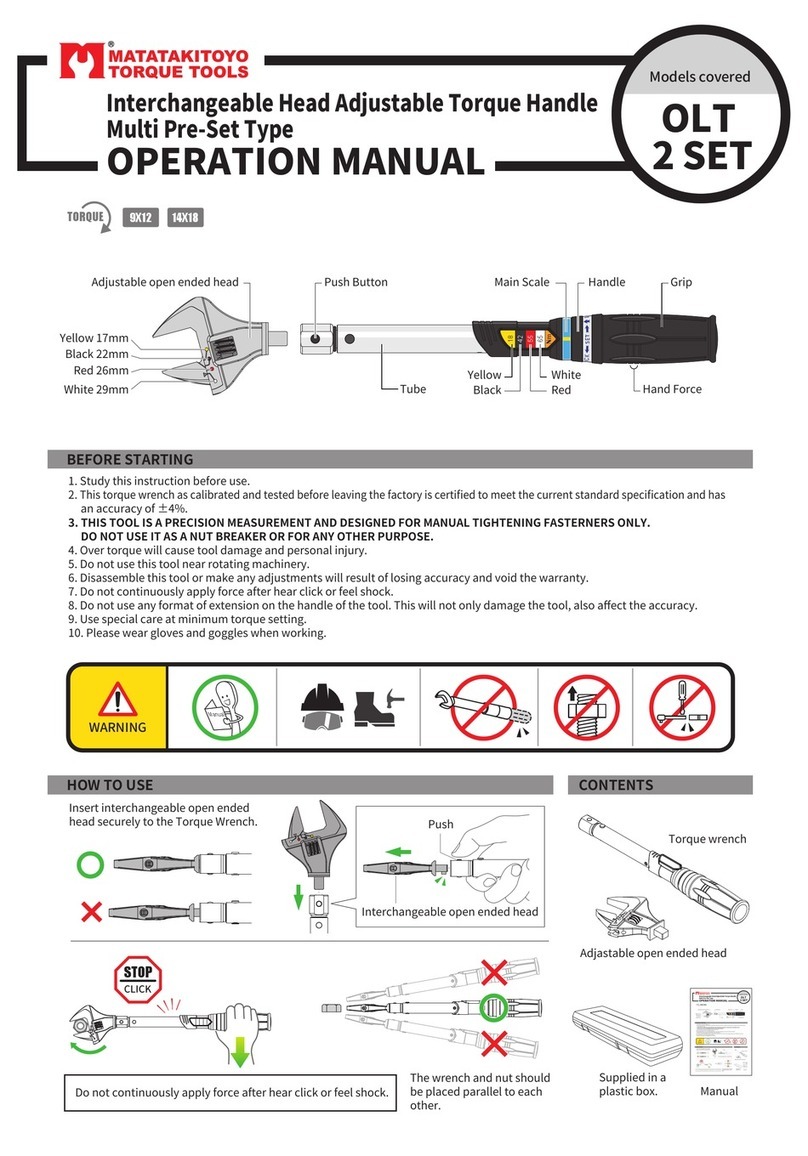

KG

9x12

9x12

9x12

14x18

9x12

14x18

14x18

14x18

MIT-150i

MIT-250i

MIT-45F

MIT-45FS

MIT-75F

MIT-75FS

MIT-150F

MIT-230F

20 in.lb

25 in.lb

3 ft.lb

3 ft.lb

5 ft.lb

5 ft.lb

10 ft.lb

20 ft.lb

30-150 in.lb

50-250 in.lb

9-45 ft.lb

9-45 ft.lb

15-75 ft.lb

15-75 ft.lb

30-150 ft.lb

50-230 ft.lb

ØDLHW

0.22

0.58

0.80

0.81

1.14

1.15

1.38

1.50

KG

ITEM NO. Range ITEM NO. Range

Metric SAE

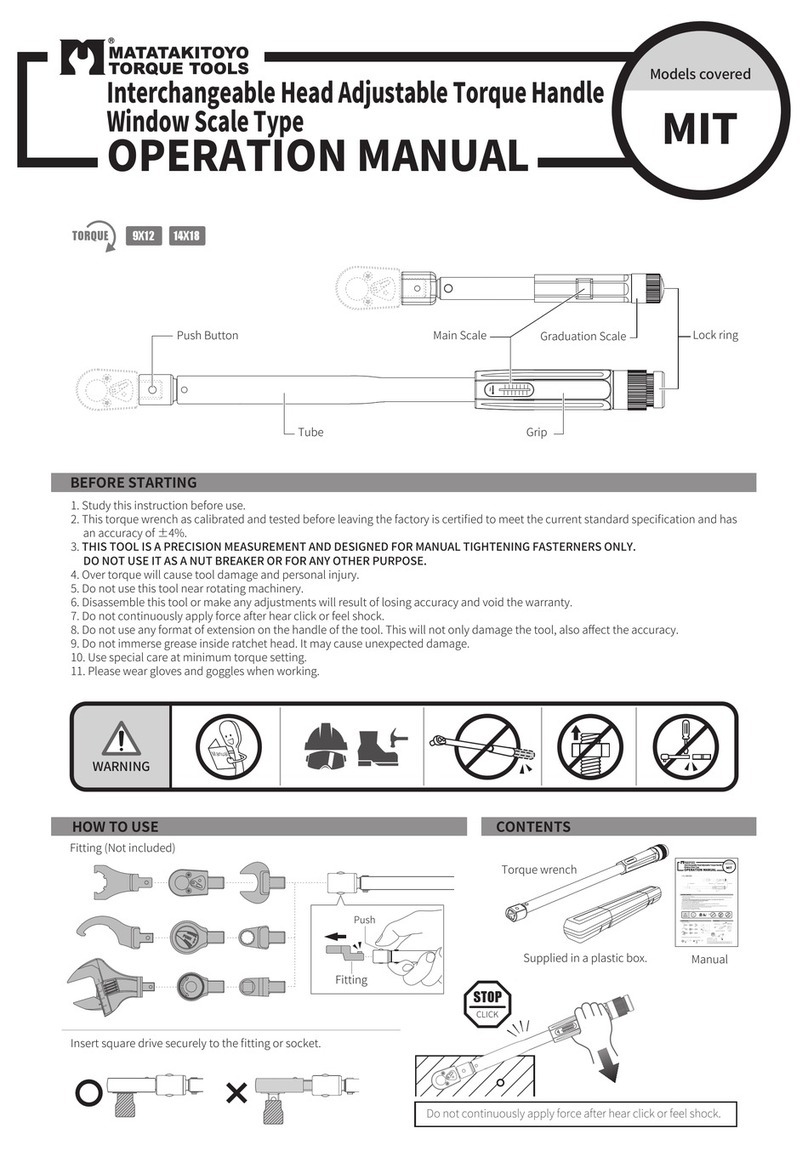

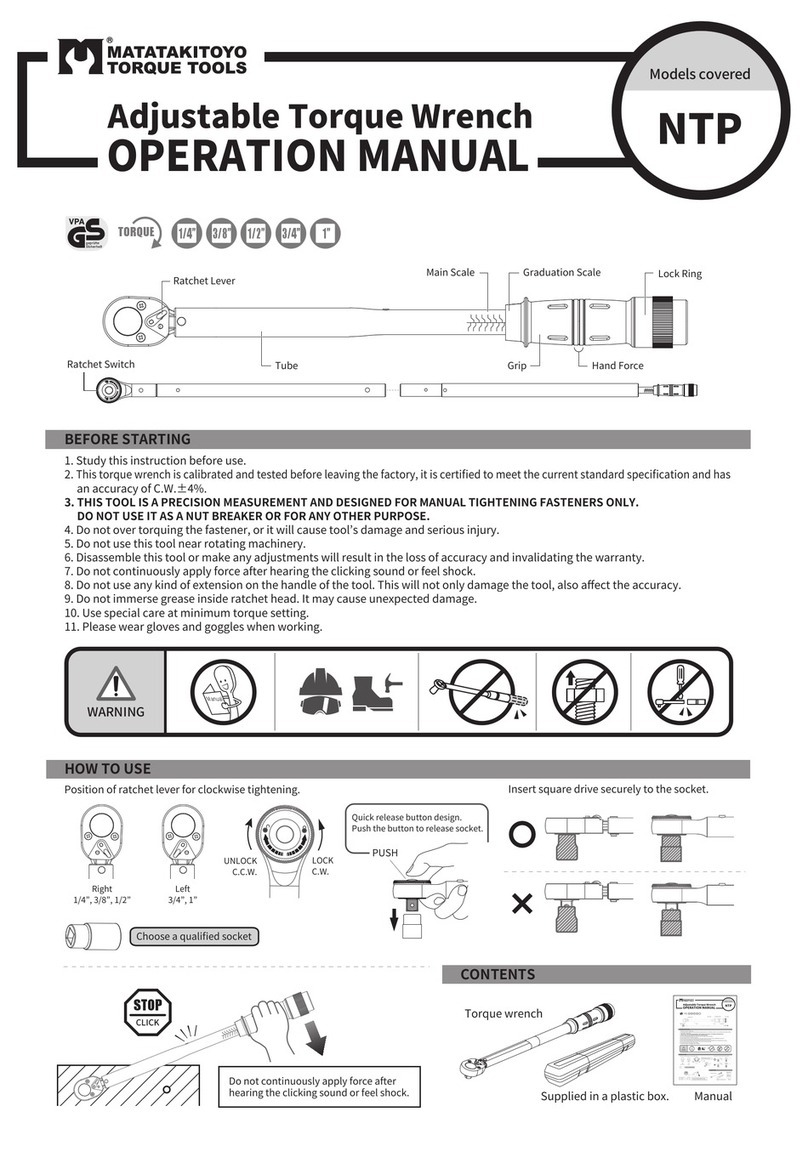

1 2 3

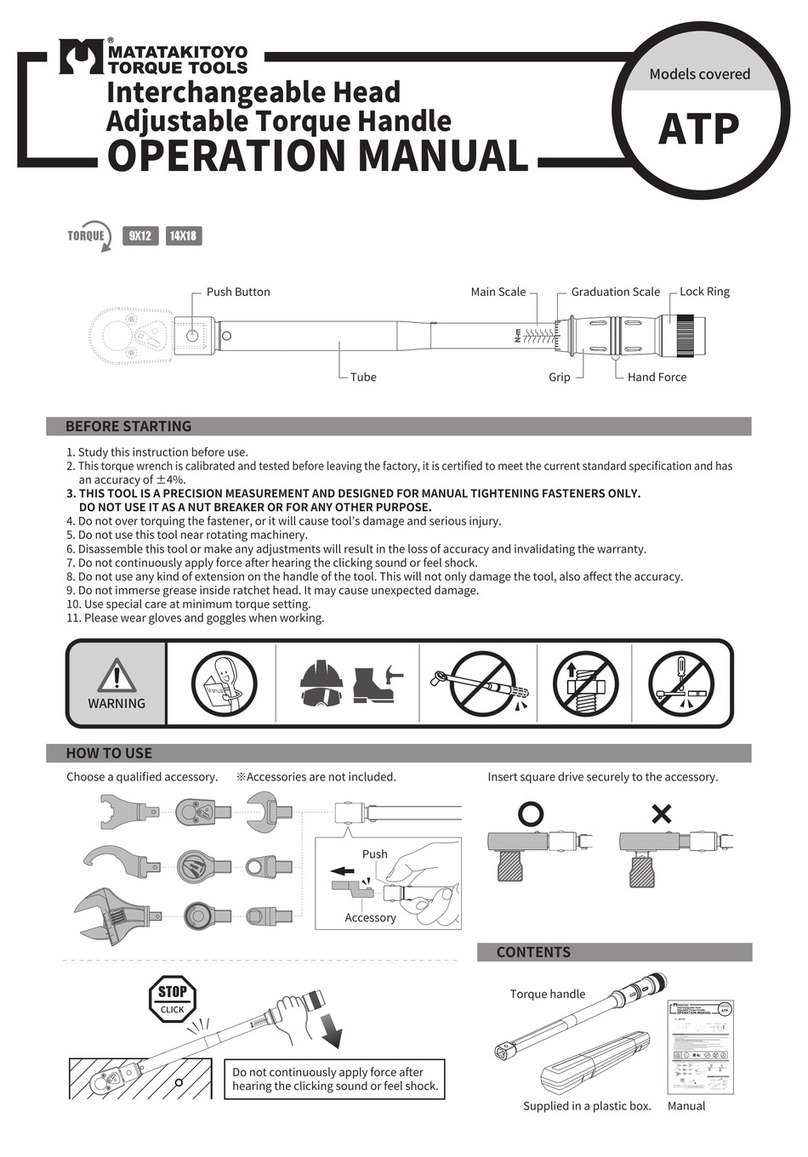

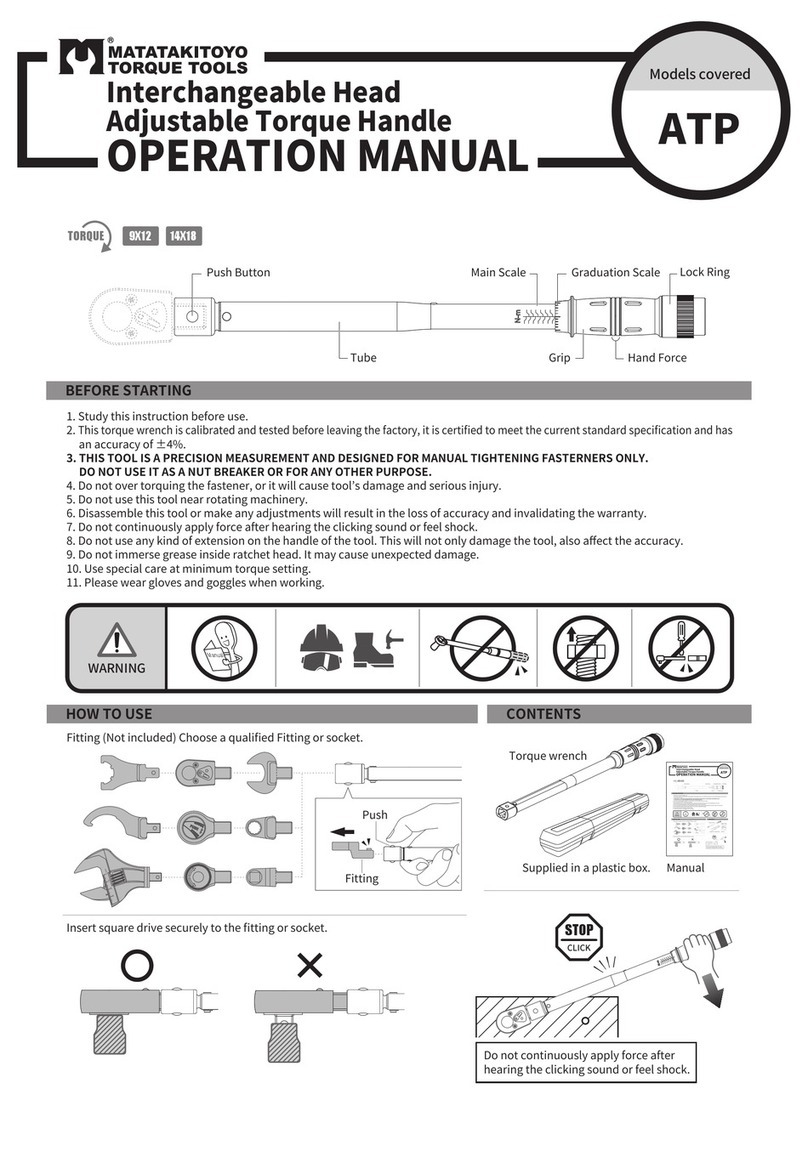

Unlock

Nm Nm Nm

Lock

Set

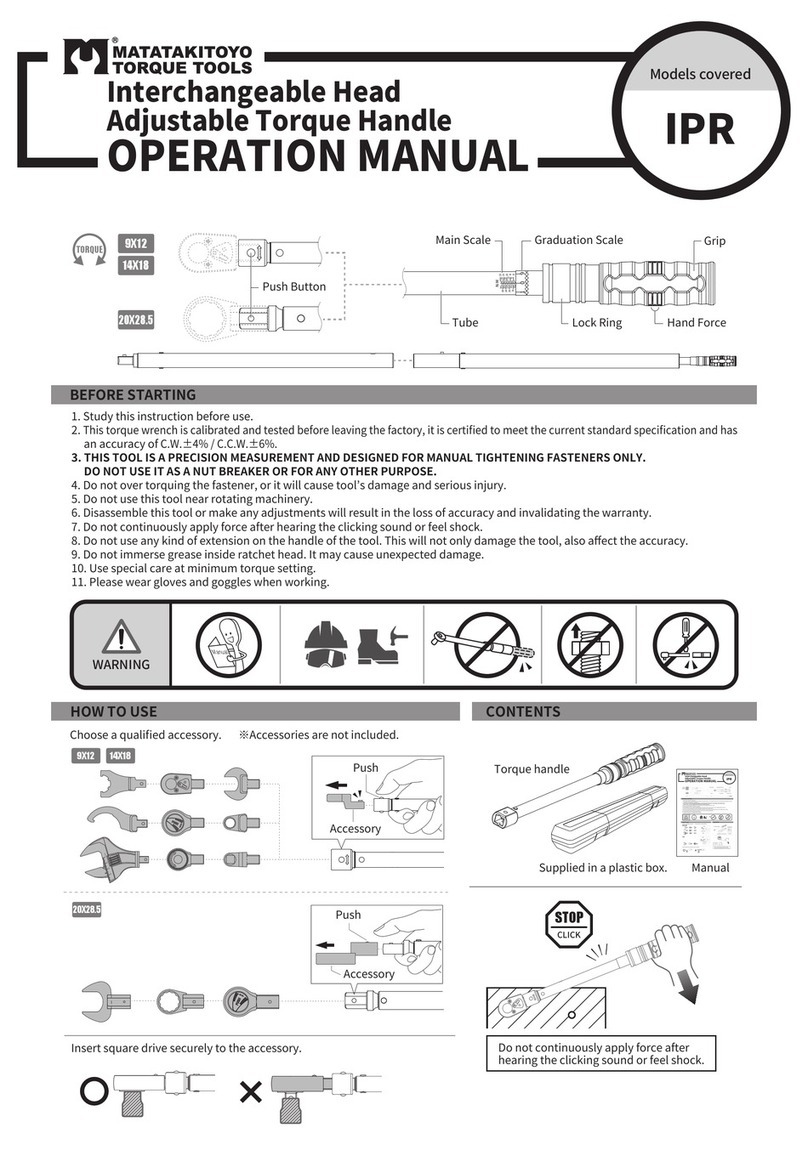

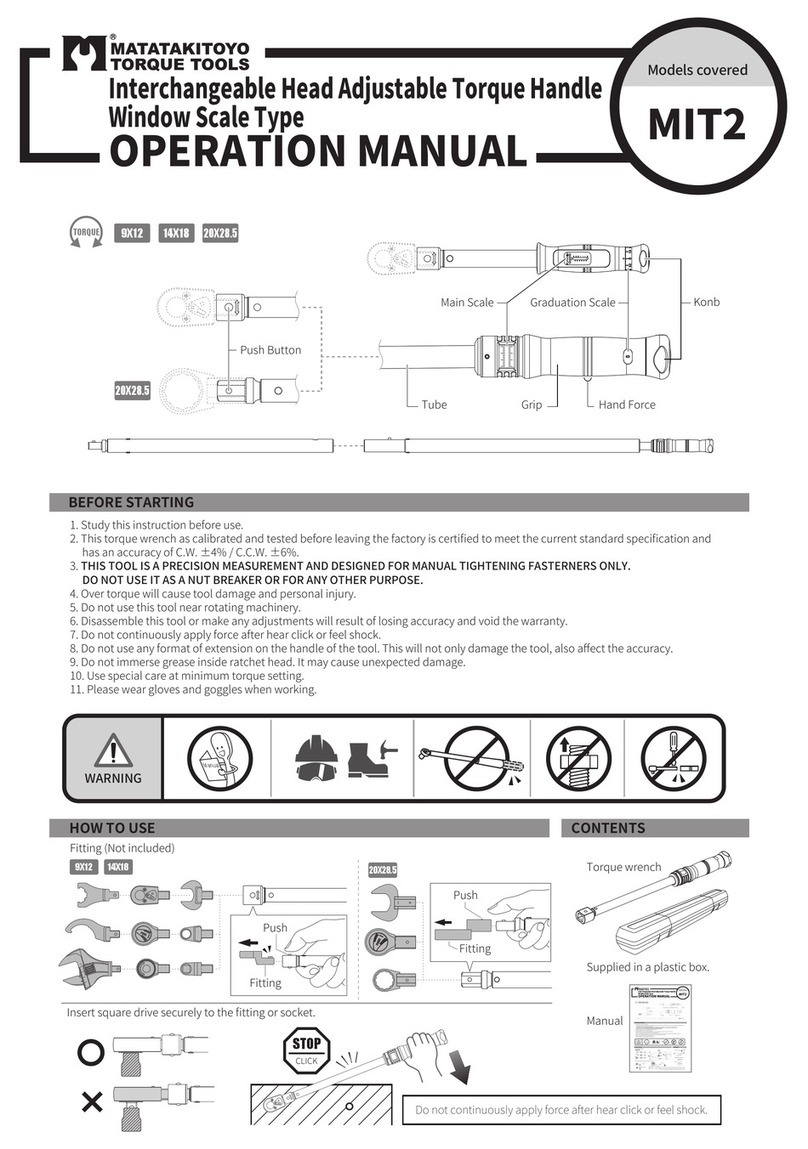

For example : ITEM NO. MIT-200N

To set torque to 130 Nm. Red line of main scale need to reach 130 Nm

(see A).

SPECIFICATION

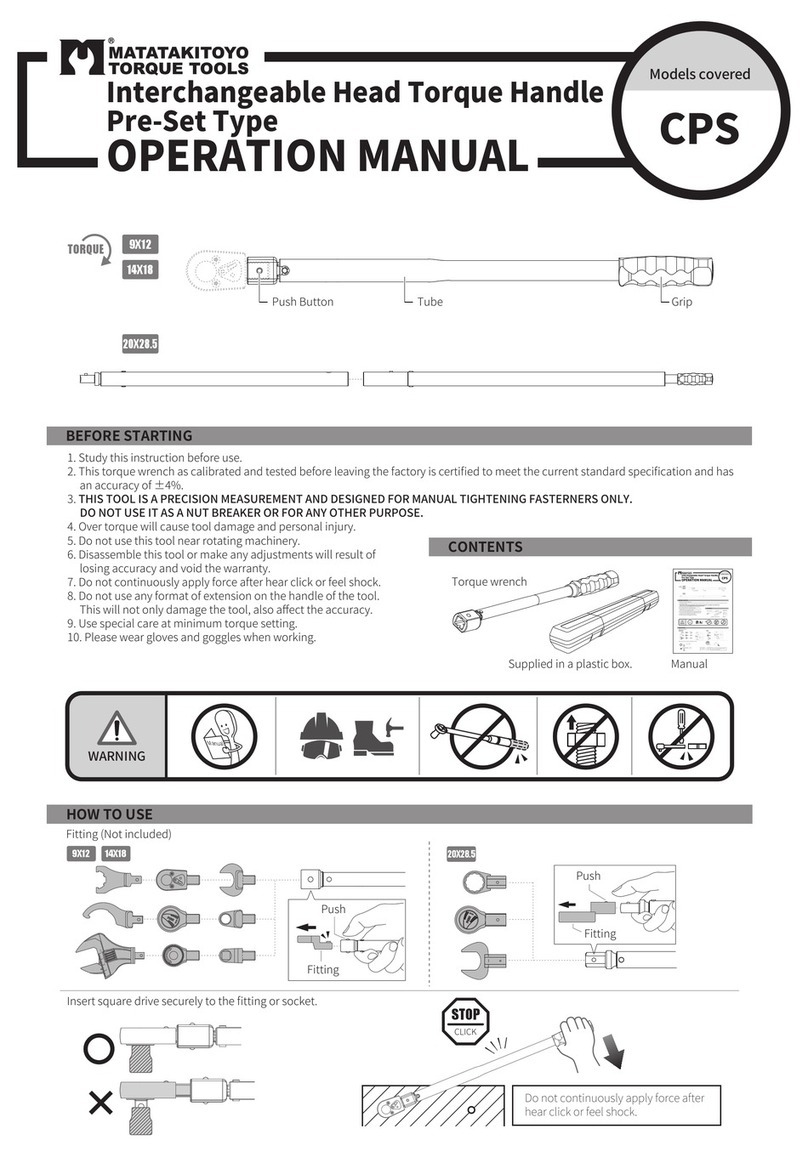

TORQUE CONVERSION FACTORS

MAINTENANCE AND STORAGE

HOW TO SET TORQUE VALUE

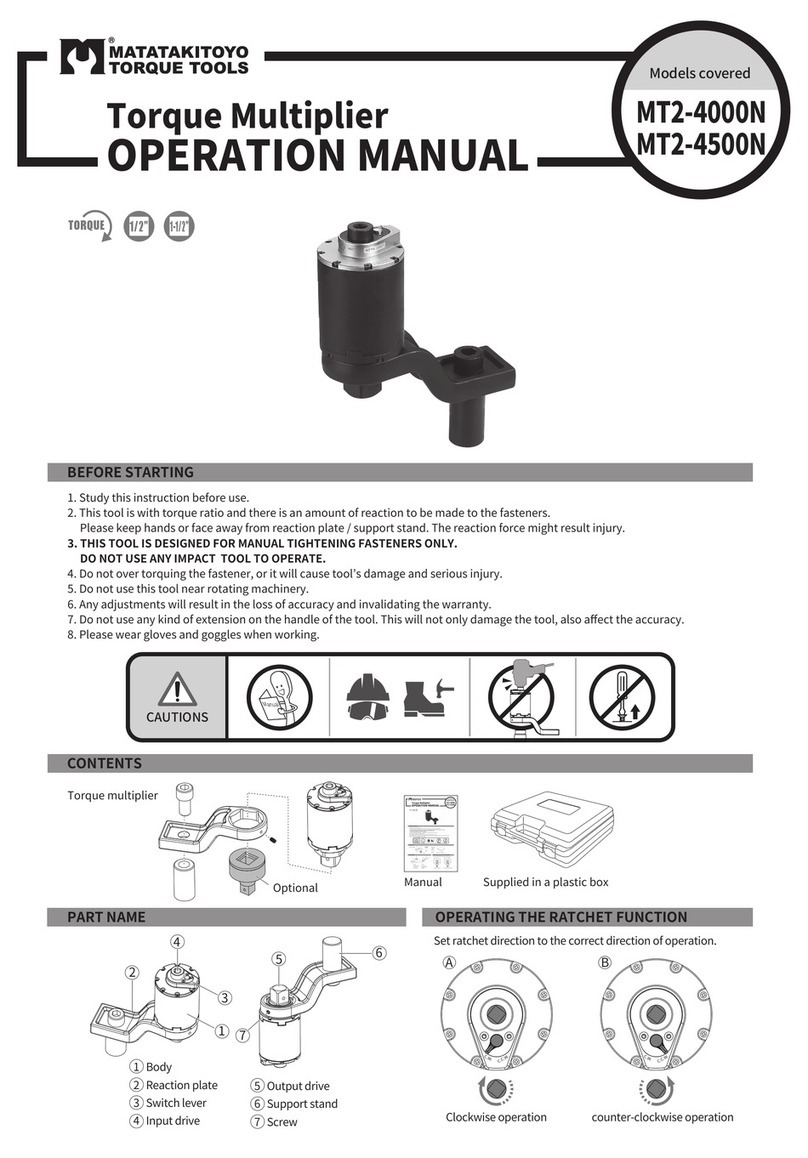

12 months

5000 cycles

Unit : mm

Accuracy : ± 4%

Units to be

converted

1 mN.m

1 cN.m

1 N.m

1 ozf.in

1 lbf.in

1 lbf.ft

1 gf.cm

1 kgf.cm(kp.cm)

1 kgf.m(kp.m)

1

10

1000

7.062

113

1356

0.098

98.07

9807

0.1

1

100

0.706

11.3

135.6

0.01

9.807

980.7

0.001

0.01

1

0.007

0.113

1.356

0.0001

0.098

9.807

0.142

1.416

141.6

1

16

192

0.014

13.89

1389

0.009

0.088

8.851

0.0625

1

12

0.0009

0.868

86.8

0.0007

0.007

0.738

0.005

0.083

1

0.00007

0.072

7.233

10.2

102

10197

72

1152.1

13826

1

1000

100000

0.01

0.102

10.2

0.072

1.152

13.83

0.001

1

100

0.0001

0.001

0.102

0.0007

0.0115

0.138

0.00001

0.01

1

=mN.m =cN.m =N.m =ozf.in =lbf.in =lbf.ft =gf.cm =kgf.cm

(kp.cm)

=kgf.m

(kp.m)

Corresponding unit

Conversion-formula :

Units to be converted × Factor = Corresponding unit

Example : Convert 5 lbf.ft into cN.m

Solution : 5 × 135.6 = 678 cN.m

1. Pull the lock ring to unlocked.

2. Turn the adjustable handle clockwise or

counter-clockwise (Right or left) to set the desired torque.

3. Push the lock ring to set finished.

1. Please return torque value to the lowest reading when not in use. (see B) Do not turn below the lowest reading.

2. If this tool has not been used for a period of time, it shall be preloaded several times at its maximum torque setting.

This will allow internal lubricant to recoat.

3. Clean this tool by wiping with a clean cloth after operation and storage in a dry environment.

Do not dip any type of liquid in this tool. This may damage the internal of this tool.

4. This tool should be recalibrated a period of 12 months, or 5,000 cycles,

whichever occurs first. To contact with local vendor or

an authorized repair center for supporting.

B

A

Jun. 2023

03

Version

www.matatakitoyo.com Made in Taiwan

MATATAKITOYO TOOL CO., LTD.

No. 63, Ln. 493, Sec. 3, Zhongshan Rd., Tanzi Dist.,

Taichung City 42754, Taiwan

TEL : 886-4-2533 5893

Manufacturer